In February 2020, Mingjie Group completed the installation of two sets of batch tire pyrolysis equipment for sale to Thailand. This Thai customer has been running several pyrolysis plants to process waste tires. They had previously purchased 5 sets pyrolysis plants from Mingjie Group.

The previous reactor door was too small, so this time our pyrolysis reactor has been improved. We have improved the size and color of the pyrolysis reactor door. The initial heating fuel for the tire pyrolysis equipment can be selected from natural gas, diesel, LPG, wood and pyrolysis oil. The synthesis gas produced by tire pyrolysis can also be recycled for internal reactor heating.

The final products of tire pyrolysis equipment are pyrolysis oil, carbon black, steel wire and synthetic combustible gas. Tire pyrolysis plant can not only solve the environmental problems caused by the accumulation of waste tires, but also turn waste into treasure. The increase of waste tires makes pyrolysis machine a new trend in tire waste management.

Waste Tire Pyrolysis Plant Manufacturer

Mingjie Group is a professional waste tire pyrolysis equipment manufacturer, we have provided customized environmental solutions to more than 200 customers around the world. And have successfully implemented a number of small, medium large-scale tire recycling pyrolysis projects in more than 30 countries, winning wide recognition.

We not only have an independent technical research and development team, but also a professional manufacturing team and sales service team. The price of pyrolysis plant is very competitive.

Advantages of Mingjie Tire Pyrolysis Equipment

- High quality: The pyrolysis reactor adopts a 16-18mm double-layer stainless steel design, which is resistant to high temperature and high pressure and is not easy to crack.

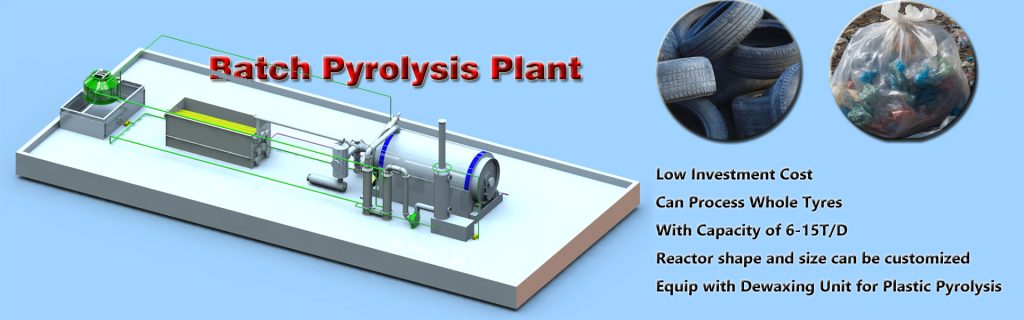

- High efficiency: The batch pyrolysis plant does not require pre-treatment processes such as cleaning, crushing, and drawing. The whole tire can be directly sent into the pyrolysis reactor. The processing capacity is 6-15T/D to meet different needs.

- High oil yield: The multiple condensation system is adopted to fully cool the oil and gas, and the oil yield is high.

- High slag discharge efficiency: Automatic spiral slag discharge is adopted to avoid fly ash phenomenon.

- Safety: Equipped with safety valves, electric pressure gauges, thermometers, and alarm safety devices, the safety of the pyrolysis plant is greatly improved.

- Environmental protection: Equipped with exhaust gas purification devices, flue gas purification devices, and carbon black collection devices, the entire pyrolysis process meets environmental protection standards.

Conclusion

Mingjie Group has designed different types of waste tire pyrolysis machines to meet the different needs of customers. Including skid-mounted small pyrolysis plant, batch pyrolysis plant, semi-continuous pyrolysis plant and fully continuous pyrolysis plant. They are suitable for waste tire pyrolysis projects of different sizes.

There are many types of waste tyres, mainly including large truck tyres, car tires, and bicycle tires. Generally, waste tires with higher rubber content and lighter wear have higher oil yields.