In April 2023, Mingjie Group completed the shipment of MJL-15 semi-continuous medical waste pyrolysis plant for sale to Guatemala. The customer sent some pictures of the equipment and said it was ready for installation.

The client planned a pyrolysis plant to process mixed medical waste. We equip the semi-continuous medical waste pyrolysis plant with hydraulic automatic feeder, spiral automatic slag discharge system, integrated oil and gas condensation system, and stainless steel dust removal system.

Component of Medical Waste Pyrolysis Plant

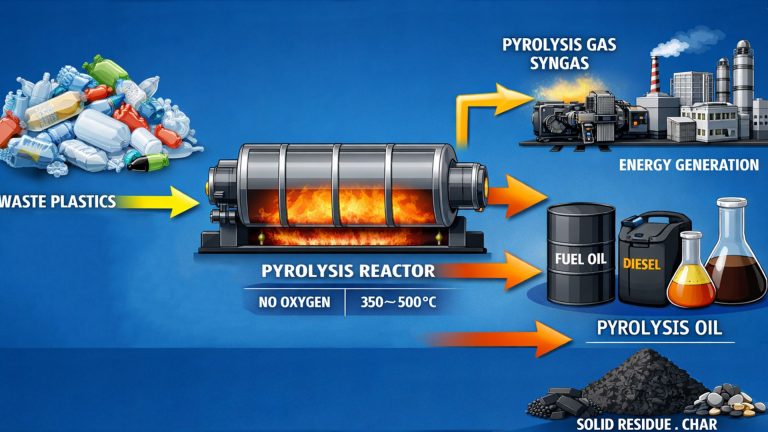

Pyrolysis Reactor

The pyrolysis reactor is the core equipment in the medical waste pyrolysis plant. And the medical waste pyrolysis process is carried out under oxygen-free or anoxic conditions. The reactor body is made of stainless steel, which is resistant to high temperature and corrosion.

Double-Layer Insulation Structure: The pyrolysis reactor adopts a double-layer insulation function. It heats the internal medical waste to a specific temperature range through an external heating system. Under the condition of lack of oxygen or hypoxia, the medical waste undergoes pyrolysis reaction. This environment can promote the decomposition of organic matter in medical waste and avoid complete combustion to produce a large amount of harmful gases and pollutants. At the same time, the pyrolysis plant realizes the reduction and harmless treatment of medical waste.

Pyrolysis Waste to Energy: In the pyrolysis reactor, the organic components in medical waste will be converted into a variety of products, such as combustible gas, liquid fuel oil and solid carbon black. These final products of medical waste pyrolysis plant have certain economic value and can be further recycled.

Sealing Structure Design: The pyrolysis reactor is usually designed with a sealed structure. It has good sealing and pressure resistance to prevent harmful gases and substances generated during the pyrolysis process from leaking into the environment. At the same time, the reactor is also equipped with corresponding safety devices. Safety equipment ensures the safety of medical waste pyrolysis plant equipment and personnel.

Stirring and Mixing Materials: A stirring device is provided inside the pyrolysis reactor, which is used to make the medical waste evenly heated in the reactor and improve the efficiency and uniformity of the pyrolysis reaction. Stirring can also promote the full mixing of materials, so that medical waste of different components can better undergo pyrolysis reaction. The stirring device prevents the accumulation or coking of materials in the reactor and ensures the stable progress of the pyrolysis process.

Automatic Feeding System

The hydraulic automatic feeder can automatically transport medical waste to the feed port of the pyrolysis furnace according to the preset program. It can accurately control the rhythm and amount of feeding according to the processing speed and feeding requirements of the pyrolysis furnace. In the end, the medical waste pyrolysis plant achieved continuous and stable feeding, improved feeding efficiency, and ensured the continuity of the pyrolysis process.

Medical waste is contagious and harmful. The feeder must ensure good sealing during the feeding process to prevent waste leakage and odor. The hydraulic automatic feeder usually adopts a sealing structure design, such as a sealing cover, a sealing ring, etc. It controls the opening and closing of the sealing device through the hydraulic system to ensure smooth feeding. At the same time, the hydraulic automatic feeding system can also effectively avoid the pollution of medical waste to the environment and ensure the health and safety of operators.

Automatic Slag Discharge System

The automatic spiral slag discharge system is mainly used to discharge the waste slag in the continuous medical waste pyrolysis plant continuously and automatically. It can achieve the functions of efficient slag discharge, slag-liquid separation, blockage prevention, and sealed transportation.

The automatic spiral slag discharge system uses the principle of spiral pushing to continuously and stably transport the waste slag from the production site to the designated discharge site. During the slag discharge process, the automatic spiral slag discharge system can usually achieve the initial separation of slag and liquid.

The spiral structure design can effectively prevent the waste slag from being blocked during transportation and ensure the normal operation of the slag discharge system. The spiral rotation can generate continuous pushing force on the waste slag, making it difficult for the waste slag to accumulate and agglomerate.

The automatic spiral slag discharge system adopts a sealed conveying pipeline, which can effectively prevent the waste slag from leaking and raising dust during transportation. This can avoid the pollution of the surrounding environment by the waste slag and keep the medical waste pyrolysis plant clean.

Oil-Gas Condensation System

The oil-gas condensation system is mainly used to process oil-gas mixture and convert the gaseous oil into liquid oil. It can realize the recovery of oil and gas, reduce oil and gas pollution and improve the quality of pyrolysis oil products.

The oil and gas condensation system realizes the recovery of oil and gas by cooling and condensing. It condenses the light oil components such as gasoline in the oil and gas into liquid and collects them in the oil tank. This not only avoids the direct discharge of oil and gas into the atmosphere, but also allows the pyrolysis oil to be reused.

Dust Removal System

The stainless steel dust removal system is mainly used to capture, separate and purify the dust generated during the pyrolysis of medical waste. It can achieve efficient dust removal, improve the working environment, protect the medical waste pyrolysis plant, avoid dust explosions and recover useful substances.

Through the rationally designed air duct and efficient filtering device, the stainless steel dust removal system can effectively capture dust particles of various sizes. Whether it is fine powder dust or larger dust particles, they can be adsorbed and collected. Ultimately, the gas meets the emission standards and reduces pollution to the environment.