Biomass charcoal making equipment uses pyrolysis technology to recycle agricultural and forestry waste, becoming the core engine to promote the circular economy and sustainable agricultural development.

The biomass carbonization plant converts biomass waste into high-value-added biochar. At the same time, it achieves carbon fixation, emission reduction and resource regeneration. Biochar production equipment can not only solve agricultural waste pollution, but also achieve carbon neutrality goals.

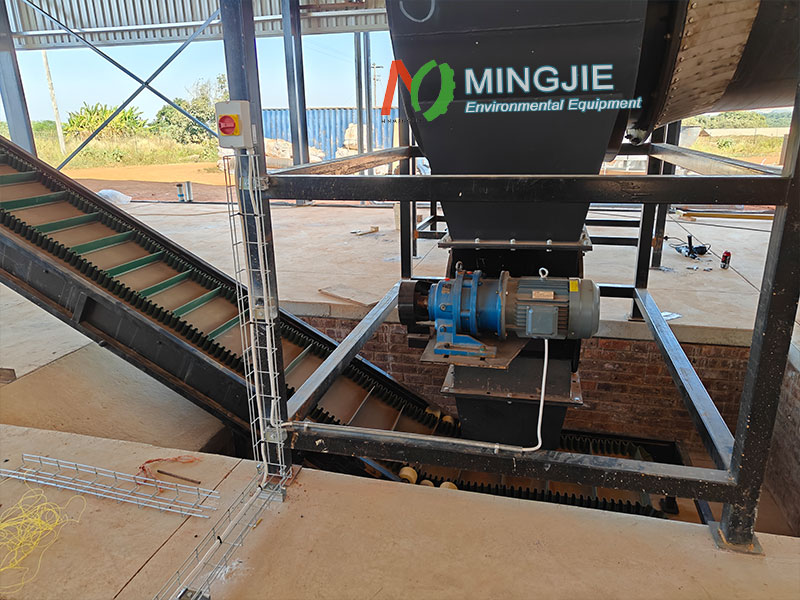

Mingjie biochar production equipment adopts a horizontal drum structure and can operate continuously for 24 hours. There is a waste biomass processing capacity of 500-5000kg/h, which can be used to process wood, rice husks, coconut shells, sludge, etc.

The biomass charcoal making equipment realizes the simultaneous drying and carbonization through a double-layer cylinder design. The biochar production equipment is equipped with a circulation pipeline and a heat exchanger to recycle the heat in the exhaust gas for drying the raw materials, reducing the dependence on external energy.

The fully enclosed operation ensures that there is no oxygen ingress and safety during the production process. The biomass charcoal making equipment is equipped with a PLC intelligent control system that can adjust parameters such as temperature and speed in real time.

The emission purification system uses multi-stage purification to reduce the tar content. The synthesis gas produced by the biomass charcoal making equipment can be used as fuel for the pyrolysis reactor.

Composition of Biomass Charcoal Making Equipment

The biochar making equipment is the core device for realizing carbonization of biomass under anoxic or low oxygen conditions. Its composition varies slightly due to different pyrolysis processes and scales, but it usually includes the following core systems.

Feeding and Pretreatment System

It can realize the storage, crushing, drying and uniform feeding of biomass raw materials to ensure the efficiency of pyrolysis reaction.

The raw material storage bin is used to temporarily store biomass raw materials and needs to be dust-proof and moisture-proof. The crushing and screening device crushes the raw material particle size to 5-20mm.

The drying system is used to dry the raw materials to reduce the energy loss in the pyrolysis process. When the moisture content of the raw materials is greater than 20%, the moisture content needs to be reduced to 15% by a dryer. The feed conveying device transports the pretreated raw materials to the pyrolysis reactor.

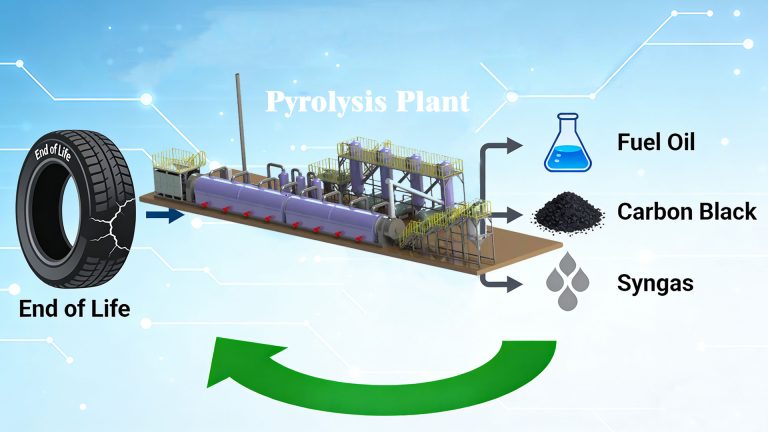

Pyrolysis Reactor System

It mainly provides a pyrolysis reaction site, controls key parameters (temperature, pressure, and residence time), and realizes thermal decomposition of biomass.

The rotary kiln reactor of charcoal making equipment drives the raw materials to move by rotating the cylinder. The inner wall of the reactor is made of high-temperature resistant alloy (such as 310S stainless steel), which can withstand temperatures of 300-1000℃.

The heating system adopts external heating and internal heating. It heats the outside of the reactor, and the heat is transferred to the raw materials through the wall. The internal heating type uses the gas generated by pyrolysis to burn in the reactor for heat supply.

The temperature/pressure control device monitors the temperature in the reactor in real time and is arranged at the feed inlet, middle, and discharge port. The pressure transmitter monitors the air pressure in the reactor and maintains it by adjusting the fan frequency.

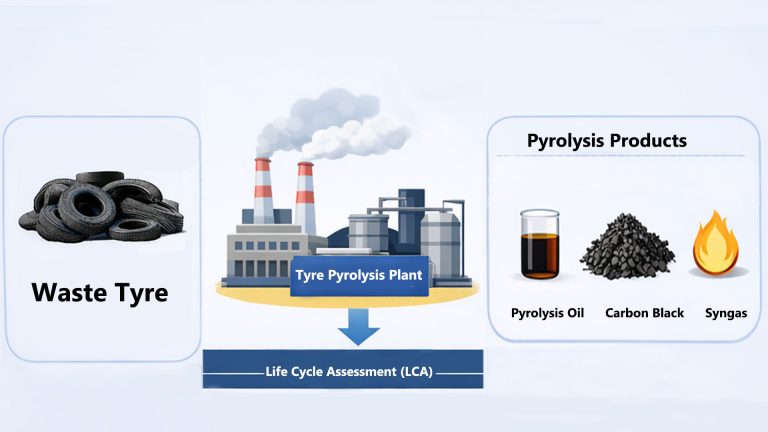

Separation and Collection System

Its function is to separate and collect the pyrolysis products (gas, liquid, solid) to achieve resource utilization.

The charcoal making equipment spiral discharger discharges the pyrolyzed biochar from the bottom of the reactor, and a water-cooled jacket is required to prevent carbon oxidation.

The liquid product is recovered by a multi-stage condensation system.

The synthetic gas product (pyrolysis gas) is treated by purification device, such as a bag filter and a washing tower. The charcoal making equipment purification system can remove particulate matter and acidic gases such as HCl and H₂S. The purified gas can be used to heat the reactor.

Energy and Power System

It mainly provides power and heat source for equipment operation to ensure continuous and stable operation of the system.

The induced draft fan provides system negative pressure to promote the flow of pyrolysis gas. The vacuum pump is used in the vacuum pyrolysis process to maintain the negative pressure in the reactor. The speed is adjusted by the frequency converter.

The heating system is mainly used for external heating process. The biomass combustion furnace produces high-temperature flue gas to heat the reactor, with a thermal efficiency of ≥85%. The gas boiler provides clean energy heating, which is suitable for scenes with high environmental protection requirements.

Automatic Control System

Its function is to realize real-time monitoring and automatic adjustment of charcoal making equipment operating parameters.

The PLC control cabinet connects sensors and actuators to achieve automatic control of feed volume, temperature and pressure. The human-machine interface displays operating data (such as temperature curve, feed speed, product output) in real time and supports parameter setting and fault alarm.

Summary

The biomass charcoal making equipment realizes the full process automation control of biomass from feeding, pyrolysis reaction to product separation through the coordinated work of multiple systems. As a professional pyrolysis plant manufacturer, Mingjie Group has 2 styles of biochar production equipment.

- Small biomass pyrolysis equipment (processing capacity of 50-100kg/h) adopts a skid-mounted design.

- Large industrial biomass charcoal making equipment (500-5000kg/h) adopts a modular layout, which is convenient for installation, commissioning and later maintenance.