Pyrolysis equipment uses pyrolysis technology to achieve the pyrolysis of plastic to fuel. Plastic pyrolysis is a technical process that decomposes plastic polymers into low molecular weight compounds by high temperature in an oxygen-free or low oxygen environment.

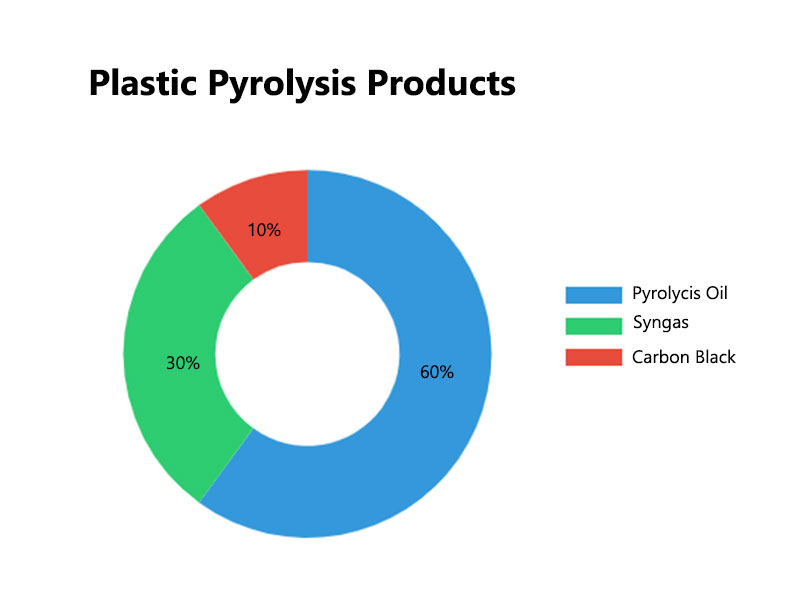

The pyrolysis reactor usually operates at a temperature range of 400-600°C, which can convert waste plastic into liquid fuel (pyrolysis oil), combustible gas and solid carbon black. Then the pyrolysis products are separated by condensation system.

Compared with direct incineration, plastic pyrolysis plant operates in an oxygen-deficient environment, which can significantly inhibit the generation of toxic substances. We equip pyrolysis equipment with advanced purification systems to ensure that exhaust gas meets emission standards.

The Pyrolysis Of Plastic To Fuel process can reduce the volume by more than 80% and convert it into high-value energy products. It is estimated that 1 ton of plastic waste can produce about 700 kilograms of liquid fuel after pyrolysis, which is equivalent to the calorific value of 0.6 tons of crude oil.

The non-condensable combustible gas produced during the Pyrolysis Of Plastic To Fuel process can be purified and reused as fuel in heating devices. This makes the heat energy required for plastic pyrolysis completely self-sufficient, without the need for external heat sources.

Pyrolysis Of Plastic To Fuel Process

Plastic Pyrolysis Oil (PPO) is used as fuel for pyrolysis plastic. Its acquisition is a systematic process, covering raw material pretreatment, pyrolysis reaction, product separation and refining. Each step has a key impact on the yield and quality of PPO.

Screening of Raw Materials

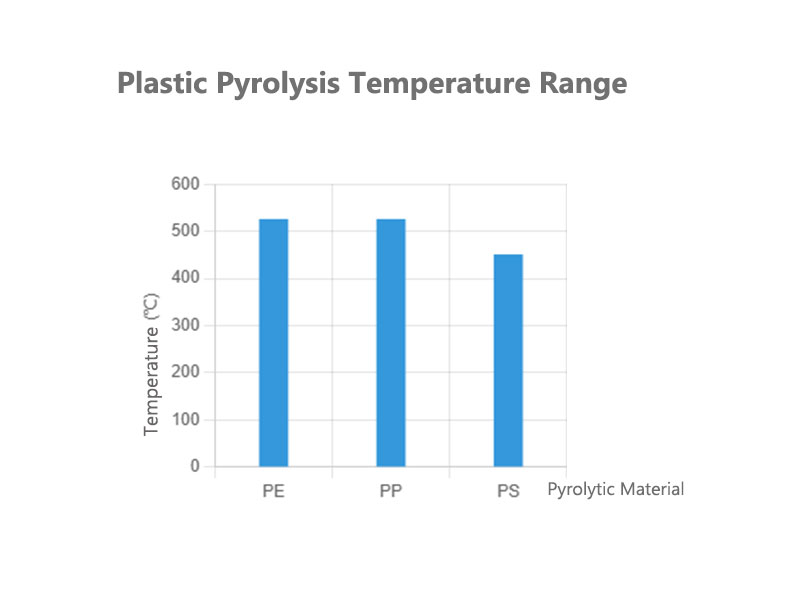

The raw materials for Pyrolysis Of Plastic To Fuel come from a wide range of sources, including discarded plastic products, industrial plastic scraps, etc. In order to obtain high-quality PPO, the collected plastics need to be sorted to separate different types of plastics, such as polypropylene (PP), polyethylene (PE), and polystyrene (PS).

Because different plastics have different pyrolysis characteristics and product compositions, pyrolysis of mixed plastics will make the products complex and affect the quality of PPO. For example, chlorine-containing polyvinyl chloride (PVC) will produce acidic gases during plastic pyrolysis process, which will not only corrode Pyrolysis Of Plastic To Fuel equipment but also pollute pyrolysis oil.

Pyrolysis Of Plastic Waste

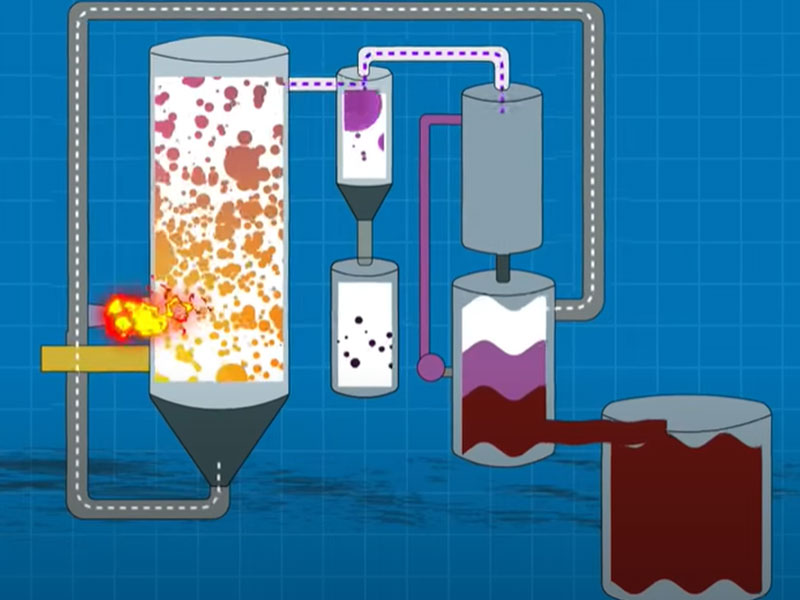

The pretreated plastic is sent to the pyrolysis reactor for reaction. The pyrolysis reactor is heated by external heating or syngas to maintain the temperature in the reactor within a suitable range. During the Pyrolysis Of Plastic To Fuel process, the plastic molecular chain breaks and gradually decomposes into small molecular gaseous, liquid and solid products.

The pyrolysis reaction time of waste plastics varies depending on the process and raw material type, generally ranging from 30 minutes to several hours. During this period, parameters (reaction temperature, pressure and residence time) must be strictly controlled to ensure that the Pyrolysis Of Plastic To Fuel reaction is sufficient and stable.

Pyrolysis Product Separation

The pyrolysis product of plastic is a mixture of gas, liquid and solid. First, the pyrolysis vapor is cooled by a condensing device to convert the condensable gas into liquid fuel, realizing the initial separation of gas and liquid. The uncondensed gas mainly contains small molecular gases such as hydrogen, methane, and ethane, which are further separated and purified by adsorption and absorption. The solid residue carbon black is separated from the system by filtering, screening and other methods.

Plastic pyrolysis oil (PPO) composition is similar to petroleum-based fuels and can be widely used in energy, chemical, materials and other fields.

Plastic pyrolysis oil can be used as a diesel blending component for diesel engines such as trucks and ships. The calorific value of plastic is about 40-45MJ/kg, and the sulfur content is low (<50ppm), which can reduce sulfide emissions. A British company mixed PPO with diesel in a 1:1 ratio and used it in garbage trucks, and its fuel consumption and emissions met EU standards.

Pyrolysis Of Plastic To Diesel

The pyrolysis oil obtained by preliminary separation contains a variety of impurities and is of low quality, so it needs to be distilled and refined.

The main principle of the waste oil distillation plant is to use the difference in boiling points of different components for separation. The pyrolysis oil is distilled through a fractionation tower to separate different fractions. Then, the quality of the pyrolysis oil is further improved through acid and alkali washing and filtration systems to meet the standard requirements for use as fuel or chemical raw materials.