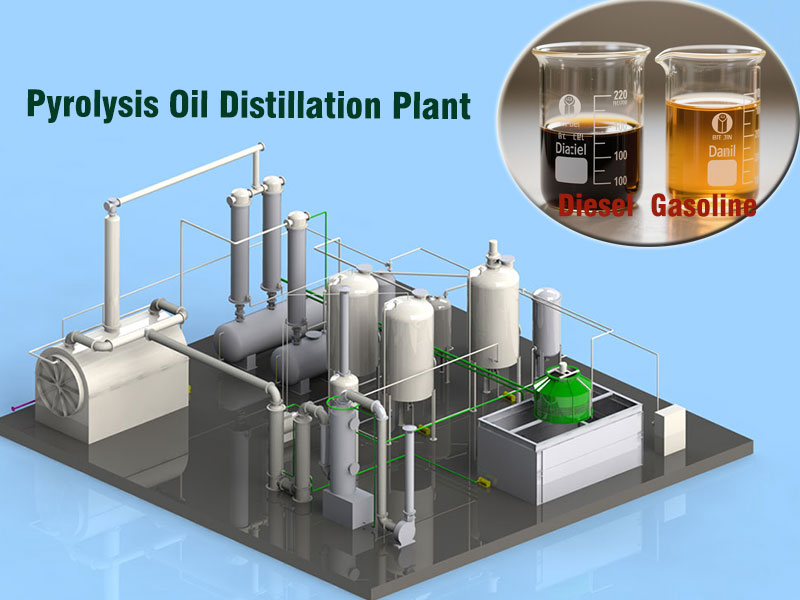

Pyrolysis technology is an effective way to treat solid waste. It can convert plastics and tires into valuable products such as pyrolysis oil, synthesis gas and carbon black. Pyrolysis oil usually contains various impurities and harmful substances. Such as sulfur, nitrogen, oxygen heteroatom compounds, and high molecular weight heavy components. This limits its further application. By distilling and purifying plastic and tire pyrolysis oil, the distillation plant can realize the conversion of Plastic Pyrolysis Oil To Diesel.

The plastic pyrolysis oil to diesel distillation project has been applied. In Europe, some companies have used plastic pyrolysis oil diesel for municipal vehicles, with a replacement rate of up to 30%.

Plastic Pyrolysis Oil

The composition of plastic pyrolysis oil varies depending on the type of plastic, but generally it mainly contains various hydrocarbon compounds.

Take the common polyolefin plastic pyrolysis oil as an example. It contains a large amount of straight-chain and branched alkanes, olefins (such as hexane, heptane, octene), and may also contain a small amount of aromatics (benzene, toluene, xylene).

At the same time, some plastics may contain additives such as plasticizers and flame retardants. There are also some organic compounds containing chlorine, phosphorus, and nitrogen atoms in plastic pyrolysis oil.

Properties of Plastic Pyrolysis Oil

From the physical properties, plastic pyrolysis oil is usually a light yellow to dark brown liquid with a density generally between 0.8 – 0.95g/cm³. It is similar to the density of conventional petroleum-based fuel oil. Its viscosity is relatively low and its fluidity is good.

However, as the content of heavy components in pyrolysis oil increases, the viscosity will increase. The boiling point range of pyrolysis oil is relatively wide, covering from low-boiling light components at room temperature to high-boiling heavy components. This also determines that plastic pyrolysis oil can be separated into different fractions in the pyrolysis oil distillation plant by controlling the temperature.

Plastic Pyrolysis Oil To Diesel

The principle of plastic pyrolysis oil to diesel is to use distillation equipment to separate the diesel component from the plastic pyrolysis oil. Then, the harmful impurities in the fraction are removed or converted by refining methods (such as acid and alkali washing, adsorption), and its key properties are improved by additives. Finally, renewable diesel fuel that meets the use requirements is obtained.

Distillation is the separation basis of Plastic Pyrolysis Oil To Diesel, and effective refining and stabilization are the key to obtaining qualified diesel products.

Plastic pyrolysis oil is a complex hydrocarbon mixture with a very wide boiling point range produced by cracking plastic macromolecules. Diesel components usually refer to fractions that boil and condense within a certain temperature range (mainly around 180°C – 350°C).

The pyrolysis oil distillation can only separate by boiling point, but the target fraction in pyrolysis oil still contains a large amount of impurities that affect diesel quality (such as oxygenated compounds, olefins, solid particles, moisture, etc.). It needs to be removed or converted through subsequent refining processes.

Pyrolysis Oil Distillation Process

Pre-treatment

Pretreatment is to remove solid particles, water or other substances that may clog the pyrolysis oil distillation tower or damage the equipment. The pretreatment methods mainly use sedimentation, filtration, centrifugal separation, and dehydration.

Generally, the pyrolysis oil is placed in a sedimentation tank first. Let it stand for a period of time to allow the water to naturally settle to the bottom of the tank under the action of gravity. Then the water is discharged through the bottom valve.

For situations where the water content is high or it is difficult to completely separate by standing, a centrifugal dehydrator can be used. Centrifugal force is used to accelerate the separation of oil and water, so that the water content in the pyrolysis oil is reduced to less than 1%.

Vacuum Distillation

Vacuum distillation (Negative Pressure Distillation) can reduce the boiling point of each component in pyrolysis oil. It avoids side reactions such as cracking and coking of pyrolysis oil at high temperature, and can also save energy. The pressure of vacuum distillation is generally controlled between 1-10kPa.

The waste oil distillation plant includes distillation reactor, oil-gas condenser, etc. The pyrolysis oil distillation reactor is the main place for heating and vaporizing pyrolysis oil, and its material is usually high temperature and corrosion resistant stainless steel. The oil-gas condenser is used to finely separate the vaporized pyrolysis oil vapor.

Depending on the different boiling points of the components of pyrolysis oil, fractions with different boiling point ranges are collected in turn during the pyrolysis oil distillation process. For plastic pyrolysis oil, the fractions collected at 100-200℃ are usually light gasoline fractions, which can be used to blend gasoline or as chemical raw materials. The fractions collected at 200-300℃ can be used as blending components of diesel fractions, and after proper blending, they can meet the use requirements of some diesel engines.

Pyrolysis Oil Refining

Pyrolysis Oil Refining the crude diesel fraction can remove harmful impurities and improve its color, odor and stability. The main methods of Pyrolysis Oil Refining include Acid Washing, Alkali Washing, activated clay adsorption, and filtration.

The conversion of plastic pyrolysis oil to diesel is an important way to realize the resource utilization and energy substitution of waste plastics. The technical route of pyrolysis oil pretreatment-distillation-refining has an industrial foundation.