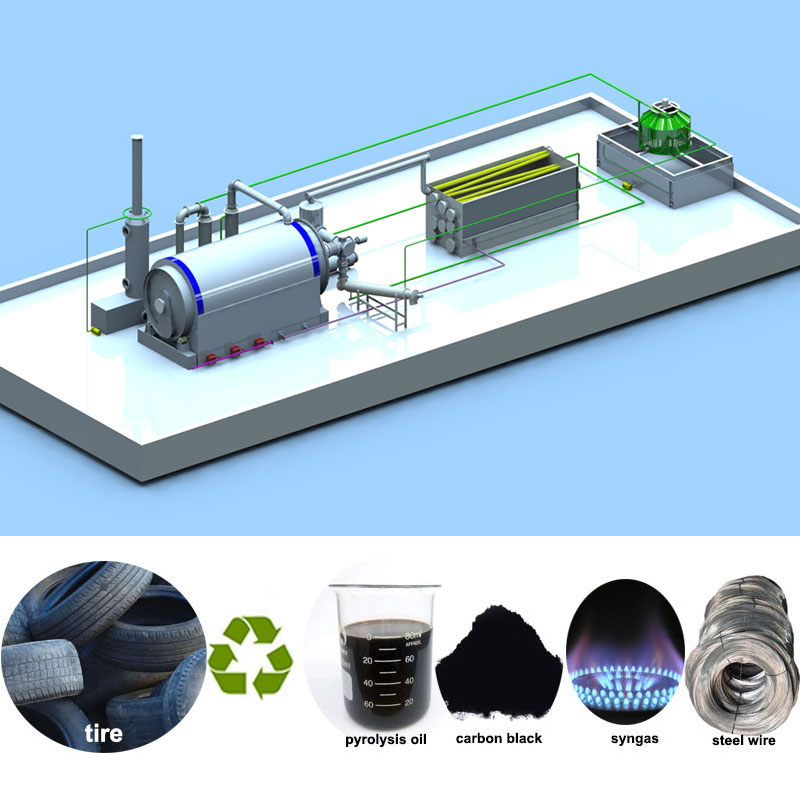

Waste tyres are converted from waste to energy through pyrolysis plant. The waste tyre pyrolysis products mainly include pyrolysis oil, carbon black, steel wire and syngas. These tyre pyrolysis products are all of economic value.

Pyrolysis oil is one of the core high value-added waste tyre pyrolysis products, with a typical yield of 40–45%. Tyre pyrolysis oil is a complex mixture of hydrocarbons. Due to its high energy density (HHV 43 MJ/kg), using it as a fuel for the combustion system is a feasible method for recycling waste tires. It can be used as an alternative energy source, helping to reduce the use of petroleum fuels and reduce the trend of its price increase.

Carbon black is the main solid product in tyre pyrolysis process, with a content of about 30-35%. The Recycled Carbon Black (rCB) is in powder form and contains impurities (such as ash, a small amount of steel wire, and heavy metals). It can be used directly as a rubber filler, plastic reinforcing agent, or activated as an adsorption material or conductive material.

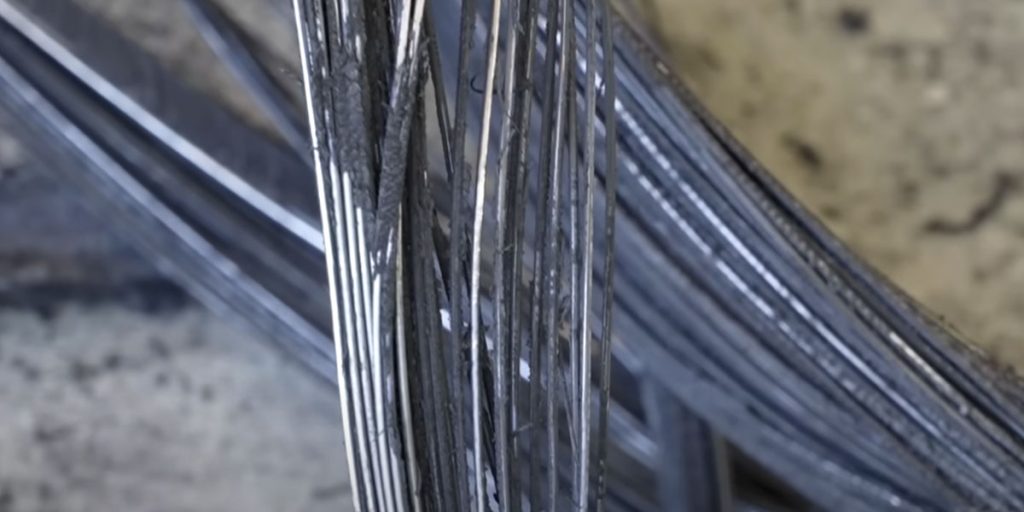

Steel wire (15%) has a high recycling value and can be directly smelted back into the furnace and reused in steel production.

The proportion of gas produced by tire pyrolysis is minimal (10%). The gas produced during the pyrolysis process has a sufficiently high calorific value. It can provide the energy required for pyrolysis, and the surplus gas can be used to generate electricity.

How to Collect Tyre Pyrolysis Products

The batch pyrolysis plant can process the entire tire. The steel wire in the tire does not undergo a chemical reaction during the pyrolysis process and the steel wire remains in the reactor. Once the tyre pyrolysis reactor has cooled, it can be pulled out.

When processing waste tires in a continuous pyrolysis plant, the raw materials need to be crushed into rubber powder without steel wire. Therefore, before the tires enter the continuous pyrolysis reactor, the steel wires need to be screened out.

The carbon black is discharged through a water-cooled spiral slag discharge system. It can be directly collected into packaging bags or storage rooms.

The oil and gas generated by tyre pyrolysis are transported to the condensation system through the gas channel, and tyre pyrolysis oil is obtained through multi-stage cooling.

Non-condensable combustible gases (methane, acetylene, carbon monoxide, and hydrogen) are collected in other storage tanks through a gas recovery device and supplied to the burner of the heating system as fuel.

How to Achieve Environmental Protection

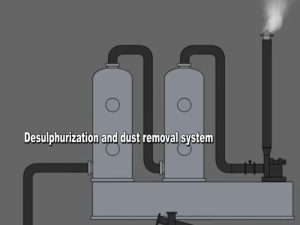

Waste Gas Treatment

Two types of waste gas emissions are generated during the waste tire pyrolysis process. The first is the tail gas generated when the waste tire is pyrolyzed in the pyrolysis reactor. The other is the waste gas generated when the pyrolysis reactor is heated. The first waste gas is a non-condensable combustible gas, which will be used again to heat the pyrolysis reactor. The flue gas purification system consisting of a desulfurization purification tower and a dust removal device will purify the second waste gas.

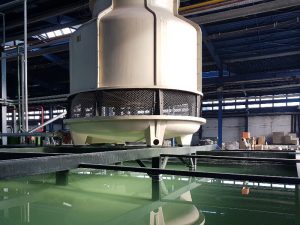

Wastewater Treatment

All the water used in the waste tire pyrolysis facility is circulating water, and there is no wastewater discharge.

Waste Solid Treatment

Recycled Carbon Black is the residue left in the waste tire pyrolysis equipment. It is a by-product of waste tire pyrolysis and can be sold directly.

Tyre Pyrolysis Oil Application

Tyre pyrolysis oil is a common industrial fuel that can replace furnace oil or industrial diesel. This fuel oil is mainly used for mechanical equipment that does not require high fuel quality, such as steel mills, boiler heating, cement plants, and even heavy fuel oil generators.

Tire pyrolysis oil can also be processed into diesel for use in heating systems, power plants and agricultural equipment (such as trucks, ships, generators, elevators, etc.). Distillation equipment can convert waste engine oil or pyrolysis oil into diesel.