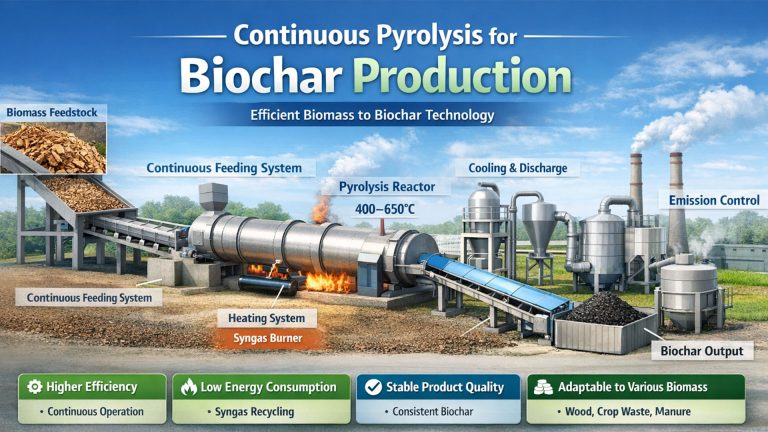

Mingjie carbonization machine has relatively mature biomass pyrolysis technology, and adopts full continuous pyrolysis to improve efficiency and quality of biochar production. The large carbonization machine cost is relatively high, and for small enterprises and farmers, the financial pressure is relatively large.

In the working process of biomass carbonization machine, energy consumption cost cannot be ignored. The pyrolysis process requires a lot of energy to maintain a high temperature environment, which increases production costs. The collection and transportation costs of biomass raw materials are also relatively high, especially in areas where the raw materials are more dispersed.

According to relevant studies, the depreciation of biochar production equipment, energy consumption and raw material costs account for 25-35%, 20-30% and 30-40% of the production cost of biochar, respectively. This leads to the lack of competitiveness of biochar prices in the market.

Carbonization Machine Manufacturers

In the global biochar machine industry, a number of competitive enterprises have emerged. These biomass carbonization plant manufacturers adopt different competitive strategies to enhance their competitiveness. Technological innovation is one of the core strategies of many enterprises.

These carbonization machine manufacturers have developed various types of biochar equipments for different application fields and customer needs. Such as large-scale continuous biochar equipments, small charcoal machines and coconut shell charcoal machines.

Mingjie Group is one of carbonization machine manufacturers in China. We have occupied a certain share in the pyrolysis plant market with its in-depth understanding of the market and good customer relations. By providing personalized solutions and high-quality after-sales service to meet customers’ special needs, Mingjie Group has won the trust and support of customers.

What is the Biomass Carbonization Machine Cost for 2,000T/D?

This question cannot be answered meaningfully. As you will see from other answers to such questions, there needs to be a detailed assessment:

What is your feedstock?

How wet/dry is it?

Does it need size reduction, if so, what are the losses and sieving/screening requirements?

What utilities doe you have, or not have?

What is your aim to pyrolyse the material?

What products are you looking to make? Charcoal, pyrolysis liquids, syngas for heat, power, CHP?

Where is the plant to be located?

What financing are you going to use?

Permitting? How easy, and what are the costs?

Such questions as these and many more need to be answered.

Advanced Equipment Determines Carbonization Machine Cost

The R&D investment of biomass carbonization plant in pyrolysis technology, equipment manufacturing, etc. For example, explore new pyrolysis processes and biochar equipment designs to improve pyrolysis efficiency and reduce energy consumption. This is the main factor affecting the biomass carbonization machine cost.

The biomass raw materials are pretreated by crushing and drying system, which is conducive to improving the uniformity of the raw materials, thereby improving the biomass pyrolysis efficiency and biochar quality.

Mingjie biomass carbonization reactor adopts advanced temperature control technology to achieve precise control of the pyrolysis process and improve the yield and quality of biochar. The reactor is resistant to high temperature, corrosion and high strength, which can improve the service life and reliability of the biochar making machine.

By introducing advanced sensor technology, automatic control technology and artificial intelligence algorithms. Biochar making machine can achieve precise control of the pyrolysis process.

The biochar making machine adopts energy recovery technology. While producing biochar, the combustible gas are collected and purified to heat the biomass pyrolysis reactor. Advanced flue gas purification system can effectively treat exhaust gas to meet emission standards.

Biochar Equipment for Sustainability

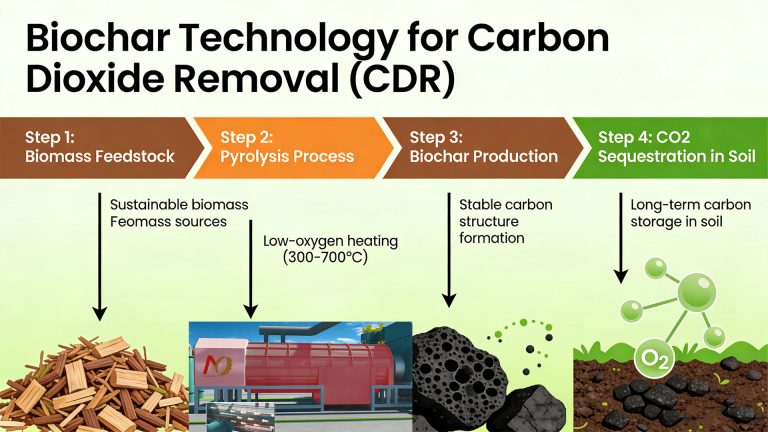

Biochar equipment is a key equipment for realizing the resource utilization of biomass waste. It has shown great application value and development potential in many fields such as environmental protection, agriculture, and industry.

- From an environmental protection perspective, biochar equipment effectively solves the problem of biomass waste treatment and reduces environmental pollution. At the same time, it plays a positive role in alleviating the greenhouse effect through carbon sequestration.

- In the agricultural field, biochar has a significant effect on improving soil structure, fertility and crop yield.

- In industry, biochar, as a raw material and energy substitute, reduces production costs and reduces harmful gas emissions.

According to relevant reports, the global biochar machine market sales reached more than 600 million US dollars in 2024, showing its important position in the market. It is estimated that by 2030, the global biochar machine market will reach 1.046 billion US dollars, with an average annual compound growth rate (CAGR) of 9.48%.