Wood biochar production is a promising method for assessing the energy content of forest biomass. Biochar is a stable form of carbon obtained by converting small wood particles through a pyrolysis process. Wood biochar can be used as a solid fuel, as well as for other applications, such as as a soil conditioner.

Large-scale wood biochar production offers a dual benefit: removing wood from municipal solid waste and utilizing it to produce valuable products. Biochar has attracted considerable attention as a soil conditioner due to its carbon sequestration capacity and its ability to improve soil aggregation, water retention, and organic matter content. Biochar is produced through biomass pyrolysis process, a thermal conversion process performed in the absence of oxygen.

A wide variety of wood products are found in municipal solid waste. These include materials such as plywood, particleboard, and furniture, as well as painted or treated wood. This waste wood can introduce pollutants into the environment, negatively impacting crops and soil.

Wood Biochar Production Process

Raw Material Analysis for Wood Biochar Production

Not all wood is suitable for biochar production, different wood types have their own strengths and weaknesses.

Common hardwoods, such as oak and maple, have high lignin contents, which allow them to form more stable biochar with a rich porous structure during pyrolysis. Lignin acts as the “skeletal support” of biochar, and a high lignin content provides structural stability. These abundant pores significantly increase the biochar’s surface area, resulting in excellent adsorption properties. These hardwood biochars are ideal for soil conditioning, helping the soil retain water and nutrients.

Softwoods, such as pine, while having slightly lower lignin content than hardwoods, grow quickly, are widely available, and are relatively inexpensive. These woods are an economical option for large-scale wood charcoal making. In the energy sector, biochar derived from softwoods can be used as fuel for heating, power generation, and other applications.

Wood Pretreatment

After selecting the wood, pre-treatment is crucial. Drying is the first step. Excessive moisture content in the wood impedes pyrolysis and consumes additional energy for water evaporation. For example, freshly felled wood can have a moisture content of over 50%. If used directly for pyrolysis, a significant amount of energy is used to heat and vaporize the moisture. This not only reduces pyrolysis efficiency but also potentially affects the quality of the biochar.

The wood’s moisture content is reduced to an appropriate range through natural air drying or artificial drying. Generally, 10% to 20% is ideal. This ensures smooth pyrolysis and improves biochar yield and quality.

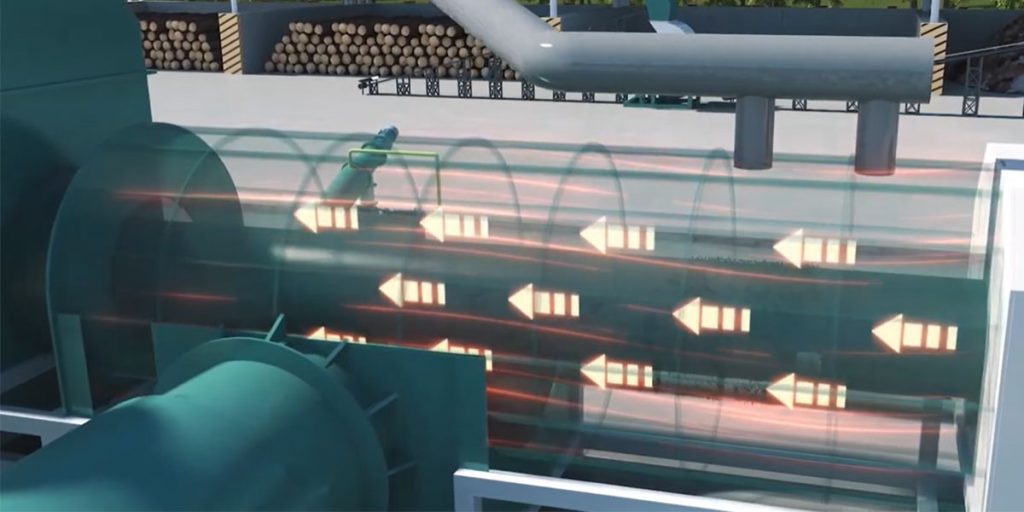

The next step is pulverization. The wood is pulverized into particles of an appropriate size to ensure more uniform heating during pyrolysis. Smaller particles allow heat to be transferred quickly and evenly throughout the wood, promoting a more uniform pyrolysis reaction. This also prevents localized overheating and incomplete pyrolysis, helping to improve the stability of the biochar quality.

Biomass Pyrolysis Process

The primary products of biomass pyrolysis are fuel gas, liquid bio-oil, and solid biochar. The biomass pyrolysis process is flexible, and product yields can be controlled by process parameters (heating rate, temperature, and residence time of steam and solids in the reactor).

In wood pyrolysis, carbonization time and temperature are important. However, the combination of these two factors (expressed in terms of heating rate) determines the properties of the resulting charcoal.

At lower temperatures, such as between 300 and 500°C, the biomass pyrolysis reaction is relatively slow, resulting in a relatively high biochar yield. The resulting biochar has a predominantly microporous pore structure, which allows for strong adsorption of small molecules such as water and ammonia. It is suitable for applications in air purification and water filtration.

As the temperature rises to 500-700°C, the carbon content of the wood biochar production increases significantly, and the microporous structure gradually shifts to a coexistence of mesopores and micropores. This significantly enhances the biochar’s adsorption capacity for organic pollutants. In soil remediation, wood biochar can effectively adsorb organic pollutants such as pesticide residues and polycyclic aromatic hydrocarbons.

If the temperature continues to rise to 700-900°C, the production of gaseous products increases significantly, and the biochar yield decreases accordingly. At this point, more amorphous carbon forms on the biochar surface, further enhancing its surface area and chemical stability. It exhibits even greater potential in industrial catalysis. In terms of time, within a certain range, longer pyrolysis times lead to more complete biochar decomposition and more stable structure and properties. However, excessive pyrolysis times not only increase production costs but may also lead to over-pyrolysis of the biochar. This damages the biochar’s pore structure and reduces its performance.

For example, in biomass pyrolysis machine using oak wood as raw material, the pyrolysis temperature was set at 600°C. A pyrolysis time of 2 hours produced biochar with a rich pore structure and moderate carbon content, which effectively adsorbed heavy metal ions from the soil. However, when the pyrolysis time was extended to 4 hours, although the biochar’s chemical stability improved, its pore structure partially collapsed, and its adsorption performance slightly decreased.

Benefits of Wood Biochar

- Biochar can significantly improve soil structure. Its rich pore structure significantly increases soil porosity.

- Biochar also has a positive and profound impact on soil microbial communities. It provides an ideal habitat for microorganisms, promoting their reproduction and growth.

- Biochar has great potential to increase crop yields and quality, providing strong support for sustainable agricultural development.

- Biochar’s strong carbon sequestration capacity makes it a powerful tool for combating climate change.

Large-scale promotion of wood biochar production and application will significantly reduce atmospheric carbon dioxide levels. It will effectively mitigate the greenhouse effect and make a significant contribution to addressing global climate change.