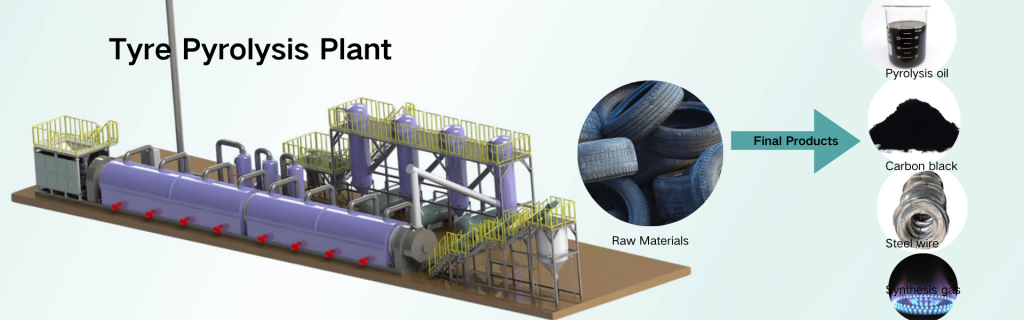

Murfitts Industries, the UK’s largest tire recycler, and tire giant Michelin have jointly announced a waste tire disposal and pyrolysis plant project. The tire pyrolysis plant focuses on recovering energy and materials from waste tires.

Murfitts plans to invest £14 million to build a waste tire recycling and pyrolysis facility at Michelin’s tire retreading plant in Stoke-on-Trent, UK. The tire recycling pyrolysis plant is expected to be fully operational by the end of 2026.

Murfitts primarily uses pyrolysis technology to generate energy from waste tires. This energy will be used to power production at the Michelin tire plant, which is expected to reduce CO2 emissions by 1,500 tons annually.

In addition to energy recovery, the waste tire disposal pyrolysis process also produces recovered carbon black (rCB) and tire pyrolysis oil (TPO).

The pyrolysis plant recovers raw materials through pyrolysis technology, treating waste tires by thermal decomposition in an oxygen-free environment. The recovered carbon black can be used in a wide range of products, including new tires. The tire pyrolysis oil can be used in other materials and as an alternative fuel.

Furthermore, this waste tire pyrolysis process produces syngas, which can be directly supplied to tire factories. This syngas can replace the natural gas produced by tire production, thereby reducing tire production’s reliance on fossil fuels.

Pyrolysis Plant for Waste Tire Disposal

Pyrolysis plant will represent a breakthrough in the tire lifecycle. They can recover energy and pyrolysis products from tires, feeding them directly back to tire manufacturers for use in the production of new tires.

Tire pyrolysis plants for waste tire disposal are a win-win for the tire industry, local governments, the national economy, and the environment.

Driven by stricter environmental policies and growing demand for resource recycling, waste tire pyrolysis technology is maturing. This technology can convert waste tires into high-value products such as pyrolysis oil and recycled carbon black, achieving efficient resource recycling.

A complete waste tire disposal system can achieve near-complete recovery of the rubber, steel wire, and fiber contained in tires.

How Does Pyrolysis Plant Recycle Waste Tires

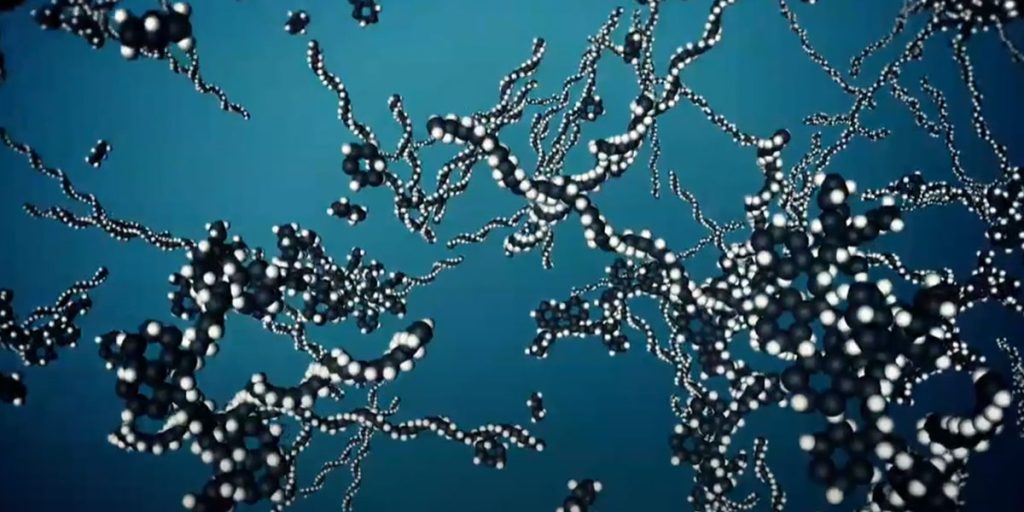

The core of tyre pyrolysis plant lies in the molecular cracking process in a high-temperature, oxygen-free environment.

In the pretreatment stage, after the tires are disassembled and separated, the rubber portion is broken into small pieces and fed into the cracking furnace.

At temperatures of 400-500°C, the rubber macromolecules break apart, producing an oil-gas mixture. This mixture is condensed and separated to produce pyrolysis oil, while the uncondensed combustible gas is recycled into the heating system.

The solid residue after tyre pyrolysis is carbon black. After grinding and pelletizing, it can be made into recycled carbon black products of various specifications.

Economic Benefits of Tire Pyrolysis Products

The tire pyrolysis process typically produces four main products, each with its own specific market and value.

Tire Pyrolysis Oil (TPO)

Comprising approximately 40-50% of the output, it is the most valuable primary tire pyrolysis product. Its price is linked to international crude oil prices and is the primary source of revenue for pyrolysis waste tire disposal projects.

Tire pyrolysis oil can be sold directly as a fuel for heavy industries (such as cement plants, power plants, and boiler rooms), offering a competitive price alternative to traditional heavy oil.

After processing in pyrolysis oil distillation plant, pyrolysis oil can be separated into light fuel oil and diesel fractions, which offer higher value.

Pyrolysis oil can also be used as a chemical feedstock to extract scarce chemicals, such as benzene, toluene, and xylene.

Recovered Carbon Black (rCB)

Comprising approximately 30-35% of the total output, rCB represents the tyre pyrolysis product with the greatest value potential. After modification and purification, the crude carbon black’s value far exceeds its value as a fuel.

Tire pyrolysis carbon black can be directly used as low-grade carbon black for the production of rubber products or as a plastic filler.

After further processing (pelletization, modification, and purification), the crude carbon black’s performance approaches that of industrial-grade carbon black. It can be used in industries such as tire manufacturing, cables, and coatings, significantly increasing its price.

Steel Wire

The output ratio is approximately 10-15%. Steel wire prices fluctuate with the scrap steel market price, are transparent and stable, and provide a stable supplementary revenue source for the project.

Tire bead wire is of high quality and can be directly sold as high-quality scrap steel to steel smelters after recycling.

Syngas

The output ratio is approximately 5-10%. Its main components are combustible gases such as methane and hydrogen. These gases are typically not sold directly, but rather recycled during the production process for heating the reactor itself. This significantly reduces the system’s external energy consumption, significantly lowering operating costs.