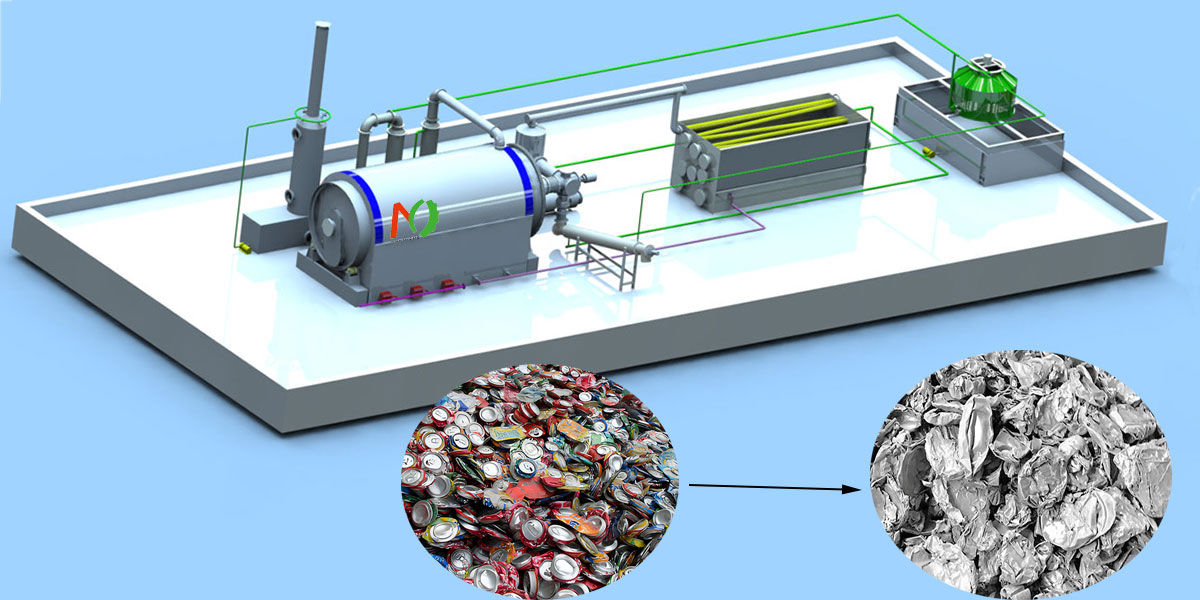

The pyrolysis device can be used in aluminum can recycling, stripping cans of paint. This is a crucial step in aluminum can recycling, removing paint, ink, and coatings from the can surface. This results in clean aluminum, which is then smelted into high-quality aluminum alloys.

The core of pyrolysis machine for removing paint from aluminum cans is to decompose the paint into small molecules through pyrolysis technology. This simultaneously prevents the aluminum can substrate from melting or oxidizing due to high temperatures, ultimately achieving separation of the paint layer from the aluminum.

The coating on the outside of aluminum cans is a complex multi-layer system. These coatings are mainly composed of high molecular polymers, such as epoxy resins, acrylics, and polyesters.

The organic components in aluminum can coatings undergo pyrolysis at temperatures between 300-500°C. In an oxygen-deficient atmosphere, the organic coating decomposes into gases and pigment ash.

Aluminum melting point is approximately 660°C, and the pyrolysis temperature is far below this. In the pyrolysis reactor, only a very thin oxide film may form on the surface of the aluminum can, while the main structure remains intact.

How Does Pyrolysis Device Remove Paint from Aluminum Cans?

Pyrolysis device primarily consists of a feed system, a pyrolysis reactor, a heating system, and an exhaust gas treatment system.

Feeding: Flattened cans are fed into the feed system via a conveyor. The feed system of pyrolysis device typically includes a silo, a belt conveyor, and a sealed feed mechanism to prevent air from entering the furnace.

Heating and Paint Stripping: The material is slowly heated to approximately 500°C to 600°C within the pyrolysis reactor. At this temperature, paint and coatings on the surface rapidly decompose and carbonize, separating from the aluminum substrate.

The pyrolysis reactor is typically a slowly rotating drum with a high-temperature resistant lining inside and an external heating system. This pyrolysis system maintains a low-oxygen environment within the furnace by controlling the feed and exhaust, preventing excessive oxidation of the aluminum.

Discharge and Cooling: The depainted aluminum flakes are discharged from the furnace tail and immediately cooled to a safe temperature. The discharge system includes a discharge seal and a water-cooled screw conveyor. This ensures rapid cooling of the aluminum material after exiting the furnace to prevent re-oxidation.

Exhaust Gas Treatment: The resulting flue gas is introduced into the exhaust gas treatment system. After thorough combustion and purification, it meets emission standards. The exhaust gas treatment system is crucial. It treats volatile organic compounds (VOCs), smoke, and small amounts of harmful gases generated during the waste pyrolysis process.

Finished Product: Clean aluminum flakes with a slight metallic luster are obtained. Metal recovery is high, and aluminum burnout is minimal (typically less than 1%).

Through the above process, pyrolysis device achieves efficient and environmentally friendly removal of aluminum can exterior paint. It is suitable for the pre-processing stage of aluminum can recycling and reuse, such as melting ingots and processing into new aluminum products.

Pyrolysis Plant for Aluminum Can Paint Removal Advantages

Compared to chemical immersion and sandblasting, modern pyrolysis plant is the only industrialized, environmentally friendly, and economical option for can stripping.

- Efficiency: Continuous production with large processing capacity (ranging from several hundred kilograms to several tons per hour).

- High Quality: Thorough paint removal ensures pure aluminum. The smelted aluminum is of high quality and contains few impurities.

- Environmental Protection: The pyrolysis device is equipped with a comprehensive exhaust gas treatment system, meeting stringent environmental emission standards.

- Economical: The value of the recovered aluminum far exceeds the processing cost, resulting in excellent economic benefits.

Mingjie Group offers a variety of pyrolysis plant types, including batch, semi-continuous and continuous pyrolysis plant. They can all be used to remove paint from aluminum cans.