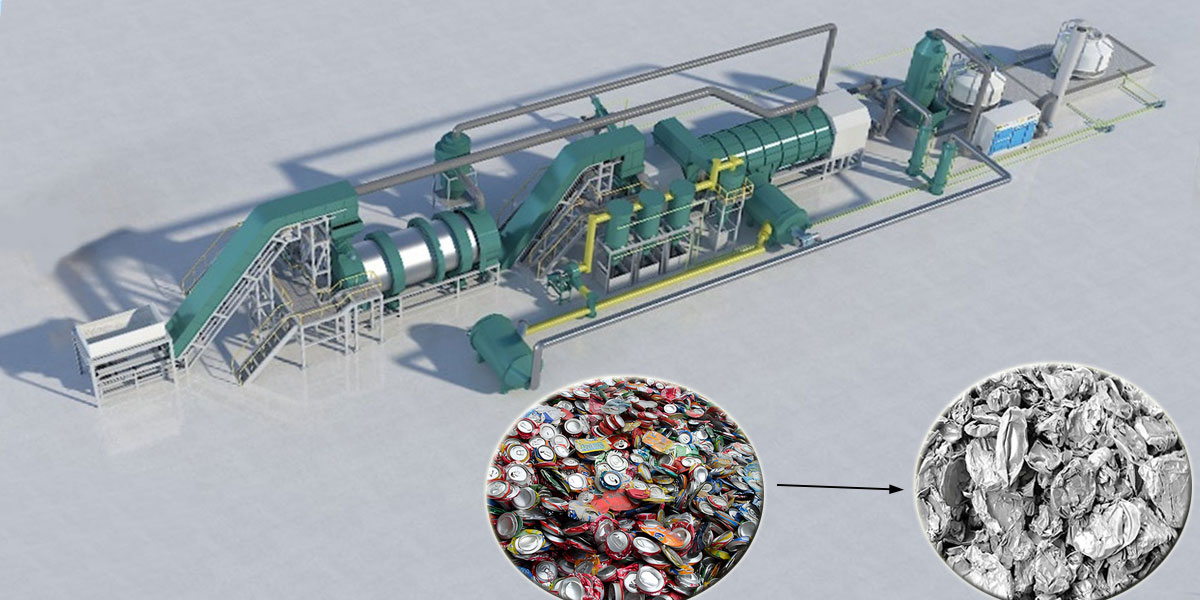

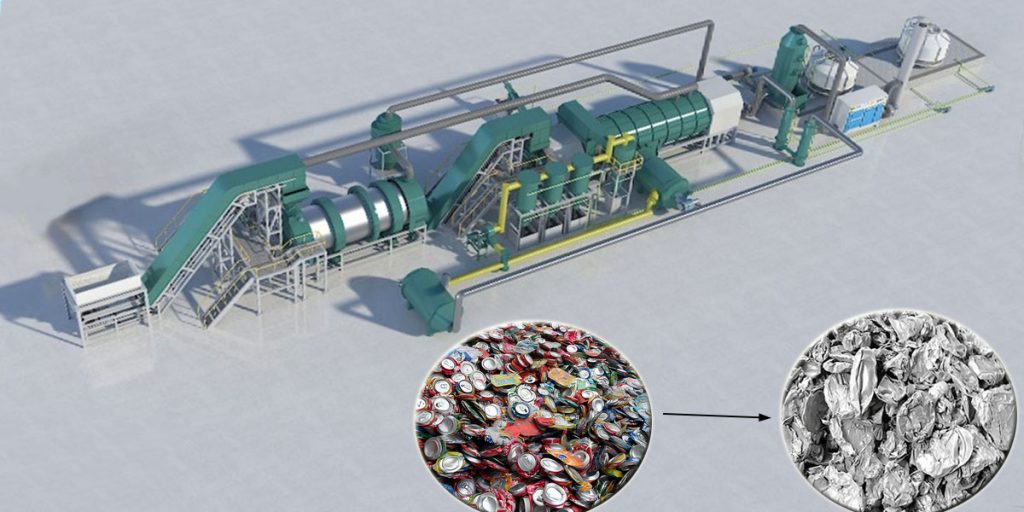

Pyrolysis carbonization equipment demonstrates significant potential and value in the field of aluminum can paint stripping. It primarily utilizes pyrolysis carbonization technology, currently the most efficient aluminum can paint stripping technology.

The paint stripping process removes organic coatings from the surface, preventing them from decomposing during high-temperature smelting and producing harmful gases that could contaminate the molten aluminum. Used aluminum cans are subjected to a rotary pyrolysis reactor at temperatures between 300 and 550°C, carbonizing and decomposing the paint layer, achieving a paint stripping efficiency exceeding 99.7%.

The accompanying flue gas treatment system incinerates the exhaust gases in a secondary combustion chamber. At the same time, the heat generated by combustion is recovered for heating. Combined with a cyclone dust collector and a spray filter, the exhaust gas meets environmental standards.

In contrast, traditional chemical paint stripping relies on acidic and alkaline reagents, which can easily cause water pollution and aluminum corrosion. Thermal paint stripping, on the other hand, uses a combination of pyrolysis technology and flue gas purification to control pollution and significantly improve environmental performance.

Aluminum Can Paint Pyrolysis Carbonization Process

Waste cans are first crushed and pre-processed before being fed into the carbonization furnace.

The temperature inside the pyrolysis carbonization equipment is controlled between 380°C and 500°C. Once heating reaches a certain temperature, heat is released primarily through the carbonization of the paint coating on the scrap aluminum.

In the high-temperature atmosphere, the paint coating on the scrap aluminum is carbonized, and the vibrations of the rotating kiln cause the paint to fall off. Simultaneously, moisture in the scrap aluminum is dried out, eliminating the possibility of water and aluminum melt reacting during the remelting process.

The high temperature cracks the organic polymers in the paint layer, converting them into combustible gases and a small amount of residual carbon. The aluminum substrate, due to its high melting point (660°C), remains solid.

The entire pyrolysis carbonization process of the aluminum cans lasts approximately 30 to 50 minutes. The final product is aluminum flakes with a paint removal rate exceeding 98%.

For thin-walled scrap with coatings or paint, the aluminum recovery rate is low if it is directly melted in the furnace. However, pre-melting with paint stripping significantly increases the recovery rate.

Advantages of Pyrolysis Carbonization Equipment

Significant Environmental Benefits: Pyrolysis carbonization equipment avoids the discharge of highly acidic and alkaline wastewater. Furthermore, through effective waste gas treatment, it reduces the emission of harmful substances such as dioxins. This significantly reduces environmental pollution.

Outstanding Economic Efficiency: Pyrolysis carbonization plant can increases the aluminum recovery rate to 92%-95%. The recycled aluminum is of high quality and can be directly used to produce high-quality recycled aluminum products, increasing product value. Furthermore, the combustible gases produced by pyrolysis can be reused for heating, achieving energy recycling and reducing production costs.

High Product Value: The aluminum flakes after paint removal are of high purity and can be directly used for smelting and casting recycled aluminum ingots. Furthermore, the combustible gases and carbon black produced by pyrolysis also have considerable economic value. The combustible gases can be reused as energy, and the residual carbon can be used to make products such as activated carbon.

Paint Stripping Application of Pyrolysis Carbonization Equipment

In practical applications, pyrolysis carbonization equipment has played a vital role in many companies.

A recycling company has achieved significant economic and environmental benefits after introducing pyrolysis carbonization equipment to process aluminum cans. Energy consumption per ton of recycled aluminum has been reduced by 15%, and flue gas treatment costs have been reduced by 40%.

A canning plant has introduced continuous pyrolysis carbonization equipment that can process 2 tons of waste cans per hour. The treated aluminum, after testing and conforming to the GB/T 3190-2020 standard, can be directly used in new can production. This achieves a high recycling rate for packaging materials.