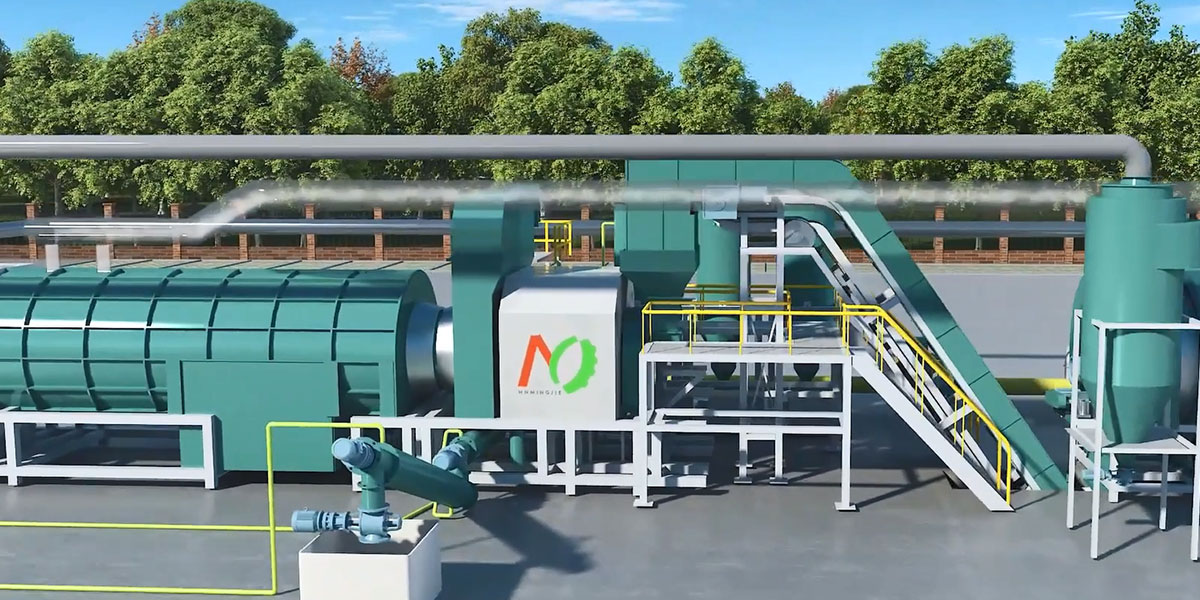

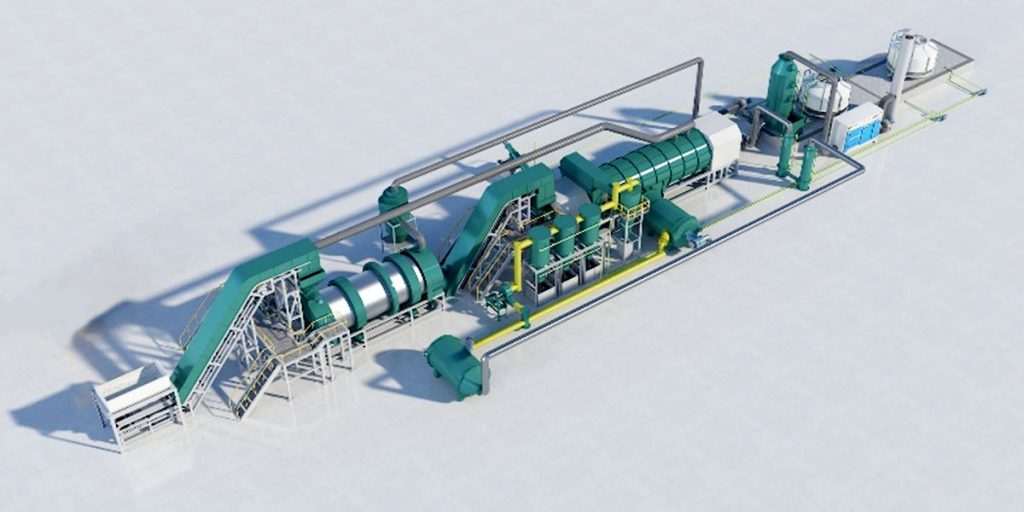

When applying pyrolysis technology to sewage sludge projects, the cost of the sludge pyrolysis plant is a significant issue. A sludge pyrolysis plant requires significant investment, encompassing a complete pyrolysis treatment system. This includes drying equipment, a feed system, a pyrolysis reactor, product separation equipment, and exhaust gas treatment equipment.

For some small sewage treatment plants or those in economically underdeveloped regions, the high cost of pyrolysis equipment can be a major barrier to the adoption of pyrolysis technology. The continuous sludge pyrolysis plant cost ranges from approximately $150,000 to $400,000 USD per daily ton of processing capacity. This means that a pyrolysis plant processing 100 tons of sludge per day could require an investment of between $15 million and $40 million USD.

Operating Cost of Sludge Pyrolysis Plant

Biomass pyrolysis plant also has relatively high operating costs, primarily encompassing energy consumption, raw material consumption, equipment maintenance, and labor costs.

In terms of energy consumption, the pyrolysis process requires a significant amount of heat energy to heat the sludge to the required temperature for pyrolysis, and this energy cost accounts for a significant portion of operating costs. Mingjie continuous biomass pyrolysis plant utilizes the waste heat generated during the pyrolysis process to dry and preheat the sludge. This not only reduces reliance on external energy sources and lowers energy costs, but also reduces carbon emissions.

Raw material consumption primarily involves auxiliary materials such as desiccants and adsorbents. While the individual costs are relatively low, they can accumulate significantly over time.

Equipment maintenance costs are also not negligible. Pyrolysis equipment operates under harsh conditions (high temperature and high pressure), making component wear and corrosion a concern. Regular maintenance and replacement are essential, increasing operating costs.

In terms of labor costs, the operation and management of sludge pyrolysis equipment requires specialized technicians, resulting in relatively high labor costs.

How to Reduce Sludge Pyrolysis Plant Costs?

The economic viability of a sludge pyrolysis project must be considered not just in terms of costs but also in terms of benefits. Ways to reduce sludge pyrolysis plant costs include co-processing and product value creation.

Co-processing: Locating the sludge pyrolysis plant near the wastewater treatment plant reduces sludge transportation costs. Using waste heat from the sludge pyrolysis plant to power the drying unit significantly reduces operating costs.

Selling biochar: Selling biochar as a soil conditioner, fertilizer, or adsorbent can generate substantial revenue. This is the most critical factor in improving the economic viability of sludge caronization project.

Energy Recovery: Utilizing syngas for grid-connected power or heat generation can also generate revenue.

Avoiding Disposal Costs: Pyrolysis significantly reduces sludge volume (>70%), avoiding the significant sludge transportation and landfill/incineration costs that would otherwise be incurred. These cost savings should be factored into the project’s economic benefits.

Policies and Subsidies: Many countries and regions offer tax incentives and subsidies for renewable energy, carbon reduction, and circular economy projects. This can effectively offset some of the initial investment.

Sludge Ppyrolysis Carbonization Project Advantage

Sludge pyrolysis carbonization projects offer multiple advantages, including pollution reduction, carbon emission reduction, and energy recovery.

Sludge pyrolysis technology converts sludge into biochar. Sludge biochar has a large surface area, abundant surface oxygen groups, and the ability to fix heavy metals and retain nutrients such as phosphorus and potassium. It can be used as a catalyst, adsorbent, and soil conditioner.

During the sludge pyrolysis and carbonization process, 93.94% of the carbon is converted into aromatic carbon and fixed in the biochar. The carbon remains in a stable state, and the pyrolysis gas produced can generate electricity and serve as a carbon sink.

Based on the accounting guidelines provided by the Intergovernmental Panel on Climate Change (IPCC) and combined with a life cycle assessment (LCA), carbon emissions from sludge treatment and disposal pathways were calculated. The results show that pyrolysis produces lower carbon emissions than traditional sludge landfill and incineration.