Recently, Mingjie company received feedback from South African customers about their waste tire pyrolysis project. The client stated that their waste tire pyrolysis project has started running and has achieved good results. The following pictures show the solid waste pyrolysis equipment running site.

The successful operation of the client’s tire pyrolysis project has profoundly impacted the waste tire processing industry and related sectors. This project has set a benchmark within the waste tire processing industry, providing other companies with successful experience and operational models to draw upon.

From a related industry perspective, the pyrolysis oil produced by the tire pyrolysis project provides a new source of raw materials for the refining industry. This alleviates the pressure of traditional oil resource shortages and reduces refineries’ dependence on imported crude oil.

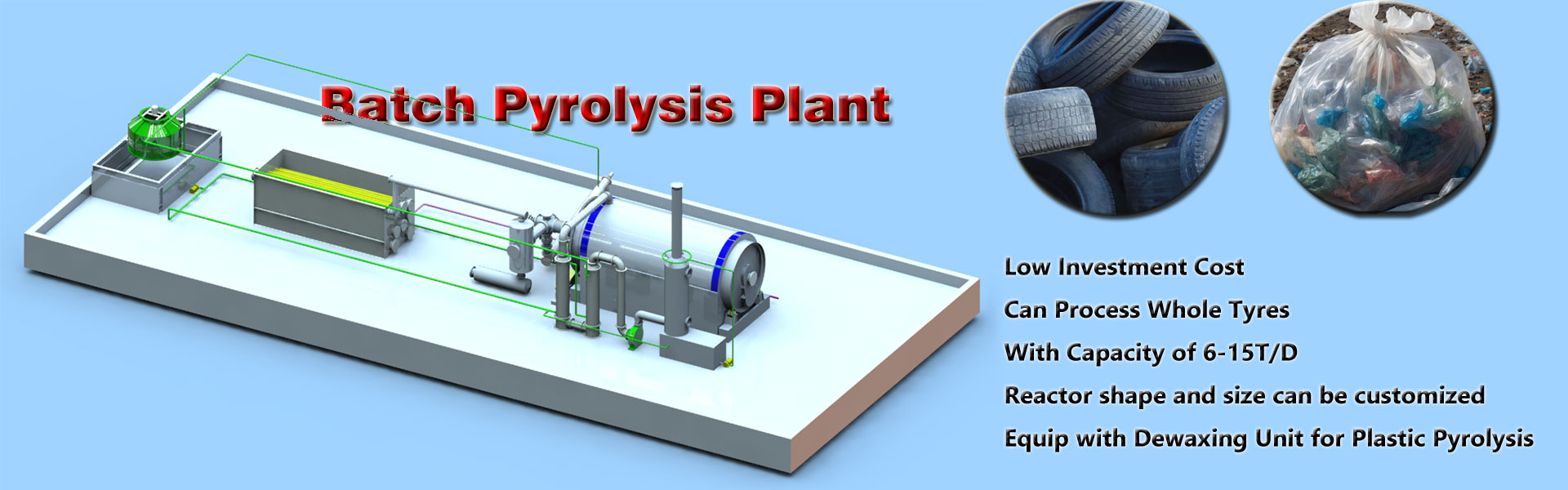

The batch pyrolysis equipment used by the customer. It offers flexibility, controllability, and adaptability, making it a preferred solution for small and medium scale waste tire recycling.

Advantages of Batch Waste Pyrolysis Equipment

Compared to continuous pyrolysis equipment, batch waste pyrolysis equipment is more suitable for small and medium-sized production capacity needs. Its core advantages are reflected in three aspects.

High adaptability to raw materials: Scrap tires do not require highly standardized pre-treatment, and can be directly processed in various specifications (passenger and truck tires). Even small amounts of rubber product scraps can be mixed in, reducing raw material sorting costs.

Flexible and controllable operation: Utilizing a “batch feed – closed pyrolysis – batch discharge” model, pyrolysis temperature, time, and other parameters can be adjusted based on raw material characteristics. For example, when processing truck tires, the pyrolysis time can be appropriately extended. This avoids the product quality instability associated with continuous equipment due to raw material fluctuations.

Low investment and maintenance costs: Waste tire pyrolysis plant occupies a small footprint, with initial investment only one-third to one-half that of continuous pyrolysis plant. Furthermore, the core components (pyrolysis furnace and condensation system) are simple in structure, making ongoing maintenance easy.

Tire to Oil Pyrolysis Project Operational Results

Economic Benefits

The client’s tire pyrolysis project has demonstrated excellent economic benefits. Through efficient pyrolysis of waste tires, the project produces a large number of commercially valuable products.

- Pyrolysis oil, one of the main products, continues to see growing market demand and maintains a relatively stable sales price.

- The finely processed carbon black has found widespread application in industries such as rubber and plastics.

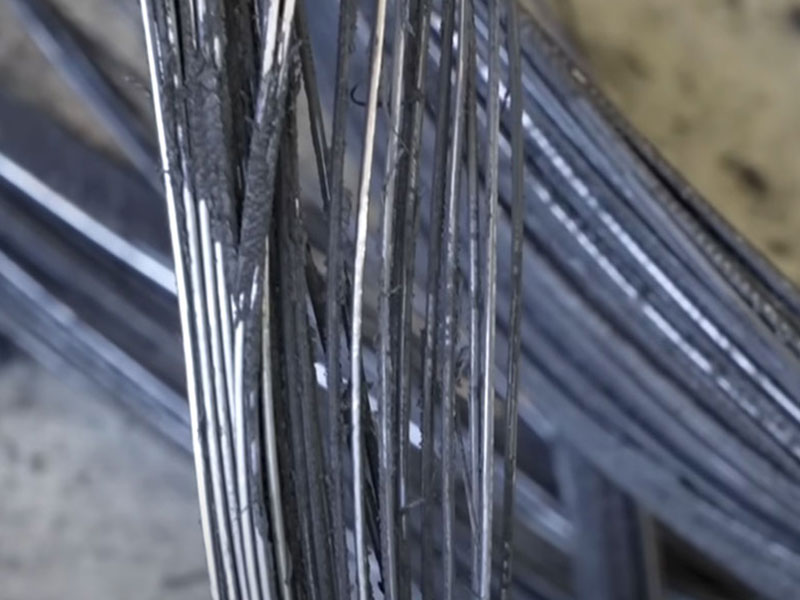

- In addition, the separated steel wire is also highly sought after by steel recycling companies.

The sale of waste tire pyrolysis products generates substantial revenue for the solid waste pyrolysis project. The waste tire pyrolysis project is highly profitable and attractive, generating significant economic benefits for the company and providing generous returns for investors.

Environmental Benefits

The client’s tire pyrolysis project has also achieved remarkable environmental benefits. Mingjie Group provides advanced pyrolysis technology and efficient exhaust purification equipment, significantly reducing harmful emissions.

Compared with traditional waste tire treatment methods, this project reduces sulfur dioxide emissions, nitrogen oxide emissions, and particulate matter emissions. This effectively improves surrounding air quality and reduces atmospheric pollution.

Regarding wastewater treatment, the waste tire pyrolysis project has established a comprehensive wastewater treatment system. This system recycles wastewater generated during the production process, reducing water waste.

Regarding waste residue, the tire pyrolysis project primarily consists of carbon black and minor impurities from pyrolysis. Through comprehensive utilization, waste residue generation has been significantly reduced, achieving zero emissions. Most of the carbon black is recycled and reused in the manufacture of rubber products, inks, and other products.

Resource recovery rate is a key indicator of waste pyrolysis to energy project environmental impact. Through pyrolysis technology, our client’s tire pyrolysis project efficiently recycles rubber, steel wire, carbon black, and other resources from waste tires. This maximizes resource utilization and reduces dependence on natural resources.