The environmental impact of continuous tire pyrolysis equipment is a complex issue that requires an objective approach. While it offers significant positive environmental benefits, it also carries potential negative impacts that must be strictly managed. The environmental impact of continuous tire pyrolysis equipment is highly dependent on the sophistication of the pyrolysis technology and the stringency of its operational management.

Positive Impacts of Continuous Tire Pyrolysis Equipment

Continuous tire pyrolysis equipment can transform tire waste into a resource. End-of-life tires are a difficult-to-degrade solid waste. Large accumulations not only occupy land, but also serve as mosquito breeding grounds and pose a fire risk. A continuous pyrolysis plant can efficiently process waste tires on a large scale, turning waste into valuable resources. It fundamentally addresses the problem of “black pollution.”

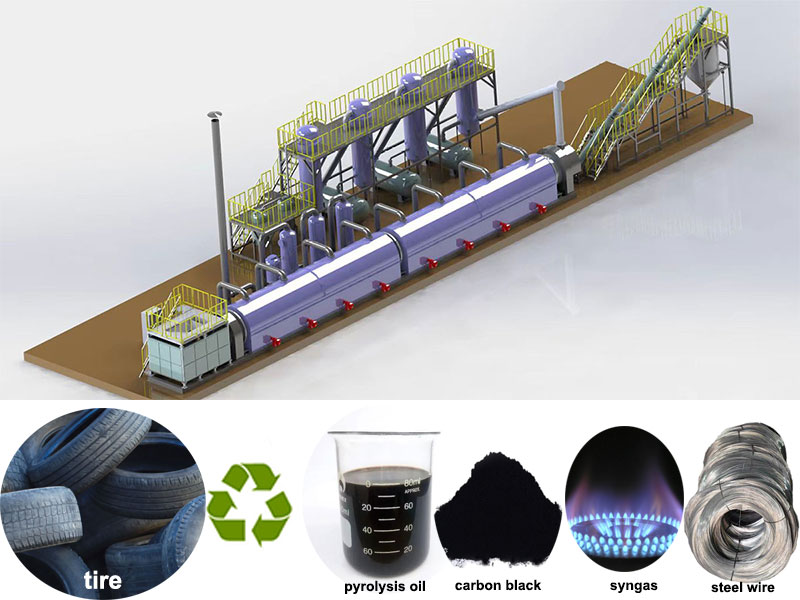

Continuous pyrolysis equipment can recover high-value resources from waste tires, including pyrolysis oil, carbon black, steel wire, and syngas.

- Pyrolysis oil can be used as fuel oil to replace some industrial fuels, reducing dependence on fossil fuels.

- Carbon black, after processing, can be used as a reinforcing agent in rubber and plastic production or as a pigment.

- Steel wire can be directly recycled as a raw material for steelmaking.

- Syngas can be recovered for reactor heating.

This aligns with the principles of a circular economy, and reduces carbon emissions and environmental pollution throughout the entire life cycle.

By recycling energy and materials, continuous tire pyrolysis equipment indirectly reduces greenhouse gas emissions associated with the production of new products.

Potential Negative Environmental Impacts

If tire pyrolysis equipment is poorly designed, improperly operated, or lacks adequate environmental protection system, it can cause serious environmental harm.

Flue Gas Treatment

Incomplete combustion of non-condensable combustible gases can produce CO and VOCs (volatile organic compounds), which can cause air pollution. A secondary combustion chamber is used to ensure complete combustion of combustible gases at high temperatures.

Poor equipment sealing during the tire pyrolysis process can lead to the leakage of VOCs and odorous gases. Mingjie’s continuous tire pyrolysis equipment utilizes a negative pressure system and advanced sealing technology to ensure continuous, sealed operation.

Dust is generated during the feeding and carbon black discharge stages. Our tire pyrolysis plant is equipped with efficient dust removal facilities, such as spray towers and baghouse dust collectors.

Wastewater Treatment

Equipment cooling water is typically recycled, which reduces the risk of contamination, but leakage prevention is necessary. A circulating cooling system can be constructed with regular replenishment to achieve zero emissions.

When condensing and recovering pyrolysis oil, a small amount of oily wastewater is generated. This wastewater has a complex composition and is highly polluting. This is a key issue to address! Wastewater treatment equipment (such as oil separation and biochemical treatment) must be installed. Treatment must meet standards before it can be reused or discharged. Direct discharge is strictly prohibited.

Inadequate ground anti-seepage measures can lead to the infiltration of wastewater and oil products. Strict anti-seepage treatment must be implemented on factory floors.

Solid Waste Disposal

Improper disposal of low-quality carbon black can create new solid waste. Carbon black can be pelletized or modified for further processing to increase its value.

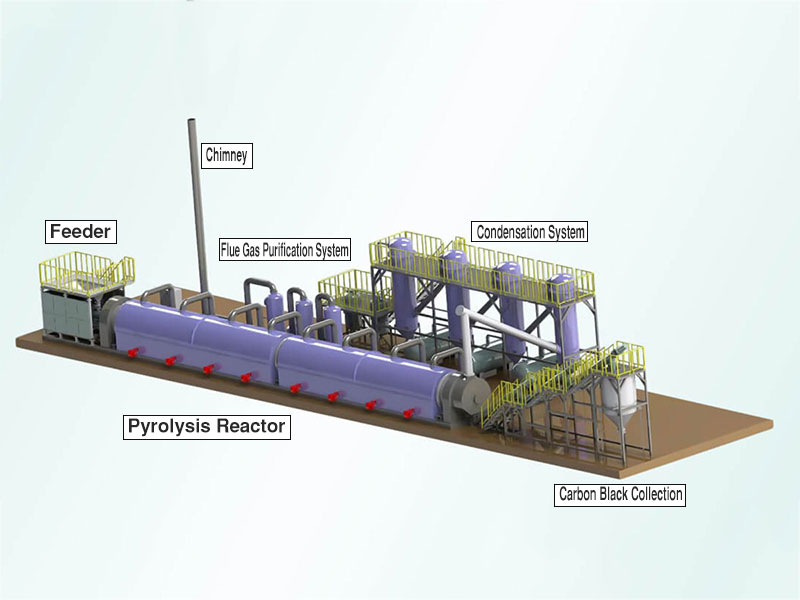

Continuous Pyrolysis Plant Manufacturer

Mingjie Group, a professional pyrolysis plant manufacturer, provides one-stop services for continuous tire pyrolysis. Under the premise of safe, environmentally friendly, and continuous and stable operation, continuous pyrolysis plants can achieve resource recovery, harmless disposal, and volume reduction of waste tires.

Continuous tire pyrolysis equipment features continuous and stable operation, intelligent control, low carbon emissions, and high economic efficiency. It boasts significant advantages in technological maturity, advanced equipment, and international recognition. Continuous pyrolysis equipment has now been commercialized.

Continuous pyrolysis equipment is widely used for various types of waste tires and rubber. The production line features a high degree of automation, with an automated intelligent control system providing real-time monitoring and processing of each system, ensuring intelligent and safe operation.

The continuous tire pyrolysis equipment operation is unaffected by external environmental factors such as weather. The entire pyrolysis process is completed within the sealed equipment pipeline, eliminating dust and VOC leakage and secondary pollution.

The non-condensable gas is purified and used as fuel for heating. It also utilizes flue gas waste heat recycling technology to save energy and reduce emissions. The material is cooled indirectly with circulating water, simplifying the process.