The waste tyre pyrolysis process involves heating waste tyres at high temperatures in an oxygen-deficient environment, breaking them down into high-value-added products. The main products of waste tyre pyrolysis are pyrolysis oil, carbon black, steel wire, and syngas.

Pyrolysis technology is currently one of the most promising technologies for achieving resource recovery and harmless disposal of waste tyres.

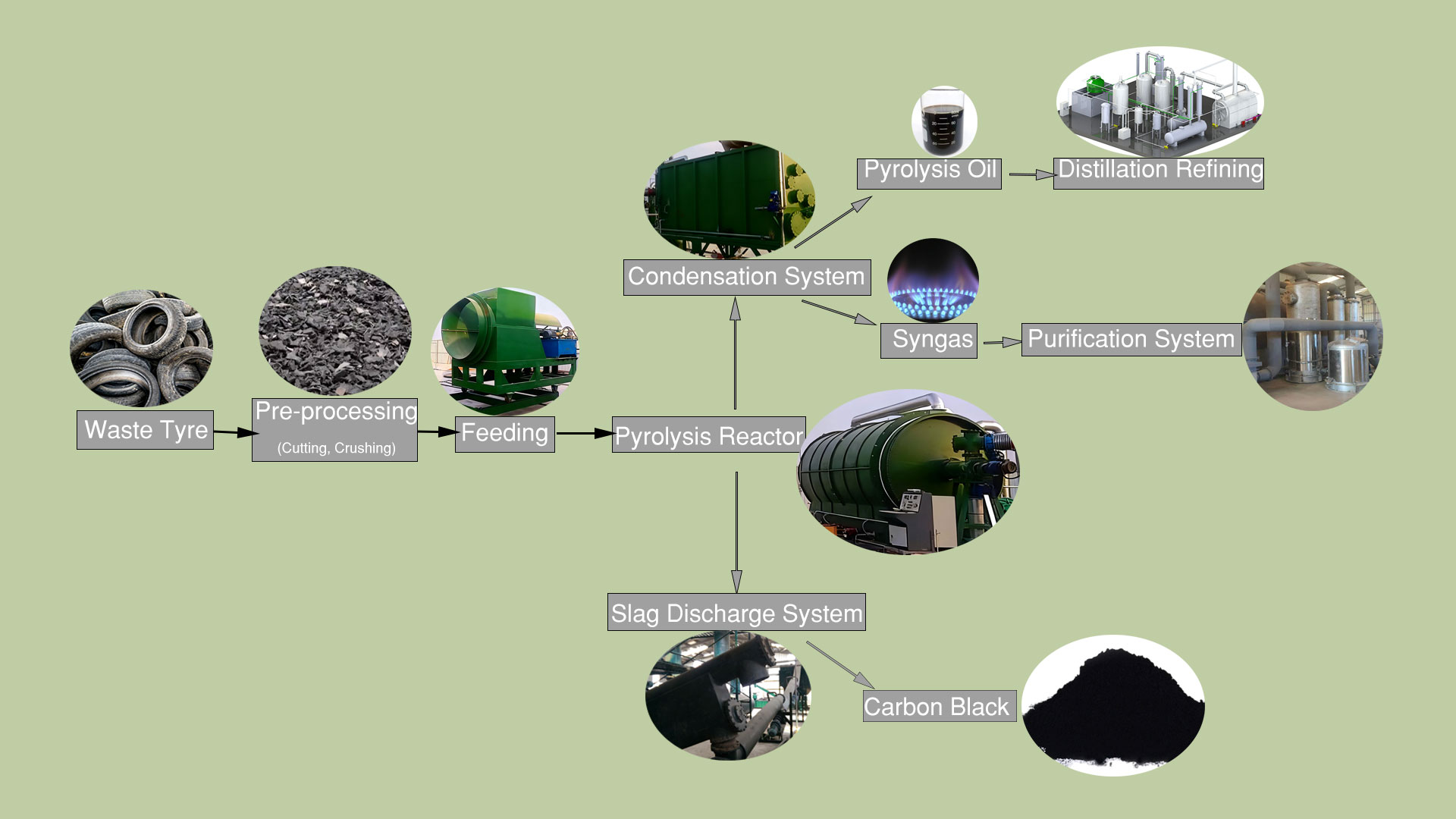

The entire waste tyre pyrolysis process can be clearly divided into the following core stages:

Waste tire – Pretreatment (cutting/shredding/steel wire removal) – Feeding (screw feeder) – Pyrolysis reaction (core step) – Carbon black collection via a slag discharge system – Oil and gas condensation (producing pyrolysis oil and syngas) – Syngas purification system to provide heat to the reactor.

Positive Environmental Impact of Pyrolysis Technology

Compared to traditional disposal methods like landfill and incineration, waste tire pyrolysis offers irreplaceable environmental advantages. Its core value lies in its mitigation of pollution across multiple environmental media: solid waste, air, and soil.

Solid Waste Reduction

From the perspective of solid waste reduction, pyrolysis technology can reduce the volume of scrap tires by over 90%. Data shows that after pyrolysis, one ton of scrap tires produces only approximately 10%-15% solid residue (primarily carbon black and steel wire). These residues can be further recycled. The steel wire can be magnetically separated and then recycled back into steelmaking, while the carbon black can be purified and modified for use in the production of rubber products, coatings, or soil conditioners.

This waste tyre pyrolysis process completely eliminates the problems of traditional landfill disposal, which include occupying land, breeding mosquitoes, and posing fire hazards. It also avoids leachate pollution caused by the long-term accumulation of scrap tires in the soil.

Air Pollution Control

In terms of air pollution control, pyrolysis technology significantly reduces harmful gas emissions. Traditional incineration directly releases large amounts of highly toxic substances, such as sulfur dioxide (SO₂), nitrogen oxides (NOₓ), and dioxins. In contrast, waste tyre pyrolysis process, conducted in an oxygen-free or oxygen-deficient environment, significantly reduces dioxin production.

Tire pyrolysis plant utilizes exhaust gas treatment systems to control emission concentrations of gases such as SO₂ and NOₓ below national emission standards.

Furthermore, the syngas (such as methane and hydrogen) produced by pyrolysis can be reused as fuel to heat the pyrolysis furnace. This can replace traditional fossil energy sources and indirectly reduce carbon emissions from fossil fuel combustion.

Pyrolysis Waste to Energy

From an environmental perspective, pyrolysis technology achieves a closed “waste-to-energy” loop through resource recycling. Waste tires are primarily composed of rubber, carbon black, and steel wire. The waste tyre pyrolysis process breaks down the rubber polymer chains, producing fuel oil (40%-50%), combustible gas (10%-20%), and recycled carbon black (30%-35%).

The fuel oil can be used as industrial boiler fuel or as a chemical feedstock. The recycled carbon black can partially replace virgin carbon black in the production of products, such as tires and rubber seals.

How to Achieve Green Sustainable Development through Waste Tyre Pyrolysis Process

To achieve the green and sustainable development of waste tire pyrolysis technology, a comprehensive prevention and control system must be established from three perspectives: technology upgrades, waste tyre pyrolysis process control, and policy oversight.

Technological Upgrades: Improving Exhaust Treatment Efficiency

To address exhaust pollution, it is necessary to optimize the exhaust gas treatment process and establish a multi-stage treatment system combining “condensation + adsorption + catalytic combustion.”

First, a condensation tower condenses most of the VOCs and particulate matter in the exhaust gas into a liquid, recovering the fuel oil. Second, activated carbon is used to adsorb the remaining small-molecule VOCs. Once saturated with adsorption, the activated carbon can be thermally regenerated and recycled.

Finally, a catalytic combustion unit completely oxidizes the difficult-to-adsorb VOCs into CO₂ and H₂O. The catalytic combustion temperature can be controlled at 300-400°C, further reducing energy consumption and NOₓ production.

In addition, high-efficiency bag filters can be used to control dust emissions during the pretreatment process.

Waste Tyre Pyrolysis Process Control

Reducing pollutant generation through process parameter optimization is key to source control. Pyrolysis temperature, heating rate, and residence time significantly influence product distribution and pollutant emissions. Excessively high temperatures increase PAH production. Excessively low temperatures lead to incomplete rubber decomposition, increasing the amount of residue.

In addition, the use of “staged pyrolysis” technology can further reduce toxic emissions.

Strengthening raw material management can also reduce pollution risks. Waste tires undergo rigorous pretreatment before entering the pyrolysis system.

- Impurities such as metal wheels and stones are removed from the tires.

- Magnetic separation is used to separate steel wire to prevent oxidation in the pyrolysis furnace, producing iron oxide dust.

- Crushed rubber particles are cleaned to remove surface oil and dust.

Policy Regulation

Sound policies and regulations are essential for promoting environmentally friendly development in the pyrolysis industry. Countries should expedite the development of specific environmental standards for waste tire pyrolysis, clarifying emission limits for exhaust, wastewater, and solid waste.

At the same time, an Environmental Impact Assessment (EIA) system should be established for pyrolysis projects. This requires that tire pyrolysis projects assess their potential impacts on the surrounding air, soil, and water before construction, and develop risk prevention and control plans.