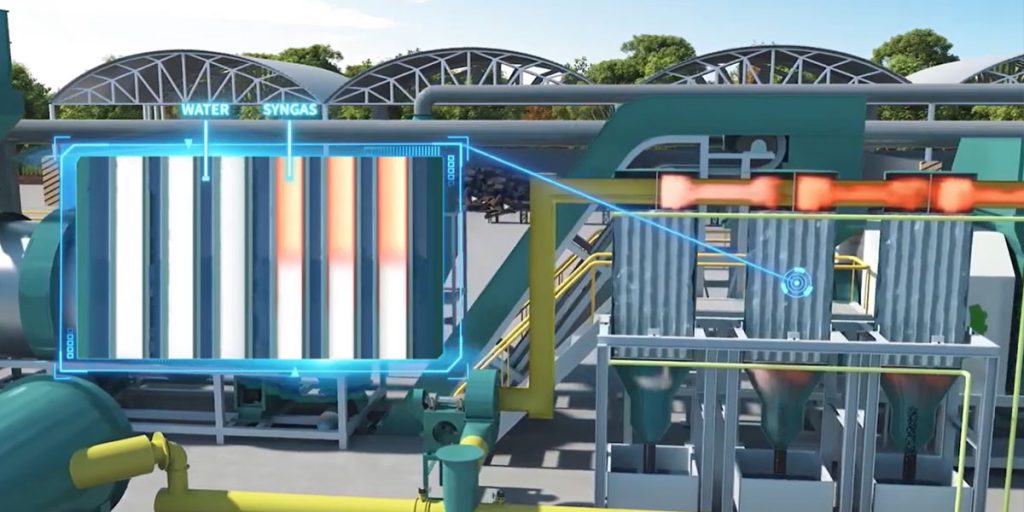

In October 2025, after the Korean customer received the machine, Mingjie Group immediately arranged professional engineers to guide the installation of biochar equipment in South Korea. The following diagram shows the installation of a biomass pyrolysis plant.

Mingjie Group has advantages in technology research and development and biochar equipment applications. We provide customized waste pyrolysis solutions tailored to our customers’ needs.

Biochar equipment in South Korea consists of several large components, including carbonization pyrolysis reactor, cooling system, separation system, and purification system. The accessories of biochar production equipment include monitoring instruments, safety devices, automatic control systems, etc. They play an indispensable role in the stable and safe operation of biochar equipment.

Preparations Before Biochar Equipment Installation

Before installing biochar production equipment, a series of preliminary preparations must be completed, including site planning and equipment inspection. Inventorying and inspecting equipment and tools is also essential. This can prevent installation delays.

Site planning is the primary task. It involves scientifically and rationally determining the installation site based on the equipment’s size, production process, and future expansion needs. Ensure sufficient space to accommodate the main equipment while also allowing for ample space for auxiliary facilities, operating corridors, and material storage areas.

If the installation site is located outdoors, climate factors must be fully considered, ensuring protective measures, such as wind, rain, and sun protection.

During mainframe installation, it is crucial to strictly follow the installation sequence. Generally, the equipment’s base support components are installed first. Next, major components (pyrolysis reactor) are installed. After hoisting the components to their installation location, they are precisely positioned and adjusted. They are then secured using bolts, welding, and other methods.

Biochar equipment in South Korea is more than just an environmentally friendly tool for handling challenging waste. It is also a key component of strategies for achieving sustainable agricultural development and addressing climate change.

Benefits of Biochar Equipment in South Korea

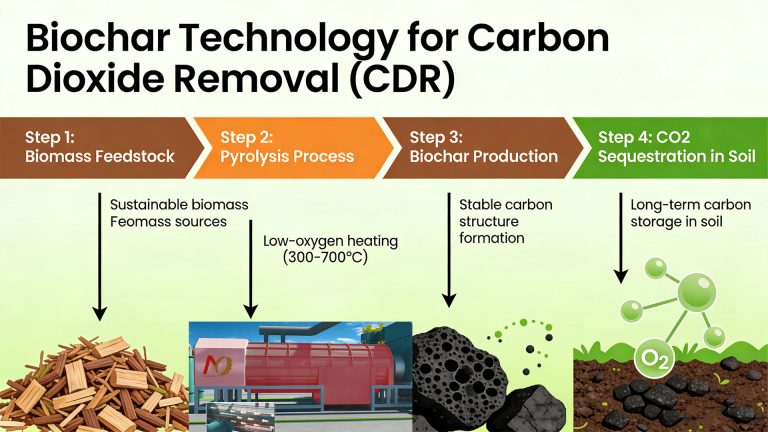

Biochar equipment processes organic waste and converts it into valuable biochar. This effectively reduces waste management costs. Compared to traditional composting or anaerobic digestion, the biomass pyrolysis process can completely kill pathogens and avoid the production of odors and leachate.

Biochar is the main product of biomass carbonization equipment. It improves soil structure, retains moisture and nutrients, and reduces the use of chemical fertilizers. Biochar equipment in South Korea contributes to sustainable agricultural development.

Biochar sequesters carbon in the soil over the long term, making it a key negative emissions technology for achieving carbon neutrality. Biochar equipment in South Korea can help businesses alleviate the significant pressure to reduce emissions. The Biochar equipment in South Korea integrates feeding, pyrolysis, tail gas treatment and char collection systems, meeting strict emission standards.

During the biochar production process, combustible syngas and bio-oil are simultaneously produced. These byproducts can be collected to provide energy for the pyrolysis process itself. Excess energy can even be used for power generation or district heating, improving the overall project’s economic viability.

Applications of Biochar Production

Soil conditioner: Biochar is applied directly to farmland to improve the physical, chemical, and biological properties of the soil.

Biocal fertilizer: Biochar is mixed with fertilizers, microorganisms, and other ingredients to create a highly effective slow-release fertilizer.

Livestock and poultry bedding: Biochar is applied to livestock farms to absorb harmful gases like ammonia, improving the breeding environment. It can then be returned to the fields after use.

Environmental remediation: Biochar has a large surface area and adsorption capacity, which can be used to treat sewage and purify soil contaminated by heavy metals or organic matter. Some environmental protection companies use biomass carbonization equipment to treat sludge and purify industrial wastewater.