On October 28, 2025, Mingjie Group completed the shipment of three sets MJ-15 pyrolysis equipment for sale to Romania. We equip these pyrolysis machines with condensation systems, advanced exhaust systems, and control systems.

The MJ-15 pyrolysis equipment for sale to Romania features a large furnace door and high processing capacity. It effectively addresses the challenges of treating both domestic and industrial solid waste.

Pyrolysis equipment plays a vital role in resource recovery and environmental protection. It heats organic matter in an oxygen-free or oxygen-deficient environment, causing it to undergo a decomposition reaction, ultimately converting waste into energy.

Why choose Mingjie Group

This collaboration stems from both parties’ shared commitment to environmental protection and their deep appreciation for advanced technology.

With the acceleration of industrialization in the Romanian customer’s region, the disposal of various types of organic waste is becoming increasingly challenging. Traditional treatment methods are not only inefficient but also place significant strain on the environment.

The customer has been searching globally for an effective solution to this challenge. The use of Mingjie pyrolysis plant in Romania projects has given the customer hope. The pyrolysis equipment’s processing capacity and environmental performance have earned their recognition.

The customer held several in-depth discussions with the Mingjie sales team via email and phone, further discussing the equipment’s technical details, application cases, and pricing.

To ensure the pyrolysis equipment fully met the customer’s needs, the Mingjie sales team also invited the customer to a site visit. Upon arrival, the customer team received a warm welcome and, accompanied by technical staff, toured the pyrolysis equipment production workshop.

During the visit, the customer raised a series of professional and detailed questions. The technical staff provided detailed and professional answers to various questions, including those regarding the pyrolysis equipment’s stability, maintenance costs, and energy consumption.

After multiple rounds of technical exchanges, business negotiations, and rigorous equipment testing and evaluation, the two parties ultimately reached a cooperation agreement.

Pyrolysis Equipment for Sale to Romania Contributes to Environmental Protection

The three sets of pyrolysis equipment for sale to Romania is not only a successful commercial collaboration, but also a significant symbol of the two parties’ joint progress in the field of environmental protection. This demonstrates both parties’ determination to contribute to the development of global environmental protection.

The pyrolysis equipment for sale to Romania will effectively reduce environmental pollution during organic waste treatment in Europe.

Utilizing advanced pyrolysis technology, pyrolysis equipment for sale to Romania can convert waste plastics into reusable resources. This significantly reduces harmful gas emissions and the environmental impact of waste. According to relevant statistics, using pyrolysis equipment to treat waste plastics can reduce harmful gas emissions by over 80%.

From a resource recycling perspective, pyrolysis equipment can convert various types of organic waste into valuable energy, achieving resource recycling. This resource recycling model is particularly important in the context of increasingly scarce global resources.

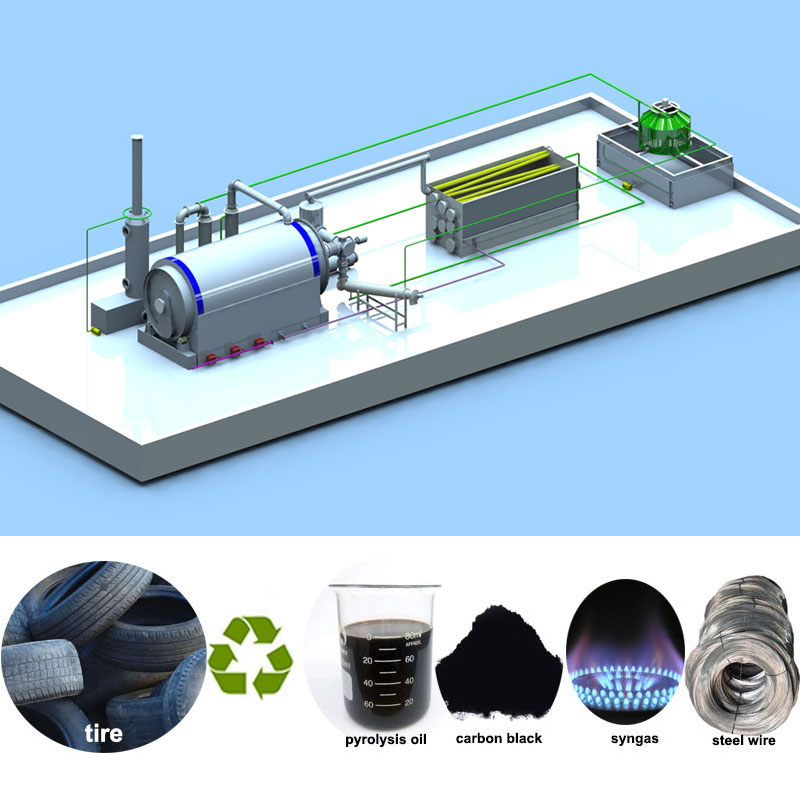

Through pyrolysis, waste tires can be decomposed to produce pyrolysis oil, carbon black, syngas, and steel wire. Tyre pyrolysis oil can be used as fuel or a chemical feedstock. Carbon black can be used in industries such as rubber and plastics, and steel wire can be recycled. This not only reduces reliance on virgin resources but also lowers waste treatment costs, resulting in positive economic and environmental benefits.

Pyrolysis equipment for sale to Romania also plays a key role in contributing to carbon emission reduction. Pyrolysis equipment can significantly reduce carbon emissions when treating organic waste compared to traditional treatment methods.

Take the treatment of oily sludge as an example. Traditional incineration produces significant carbon dioxide emissions. Pyrolysis equipment, however, uses pyrolysis technology to convert the organic matter in oily sludge into fuel oil and combustible gas. This achieves energy recovery and reduces carbon dioxide emissions. It is estimated that using pyrolysis equipment to treat oily sludge can reduce carbon emissions by approximately 1.5 tons per ton.