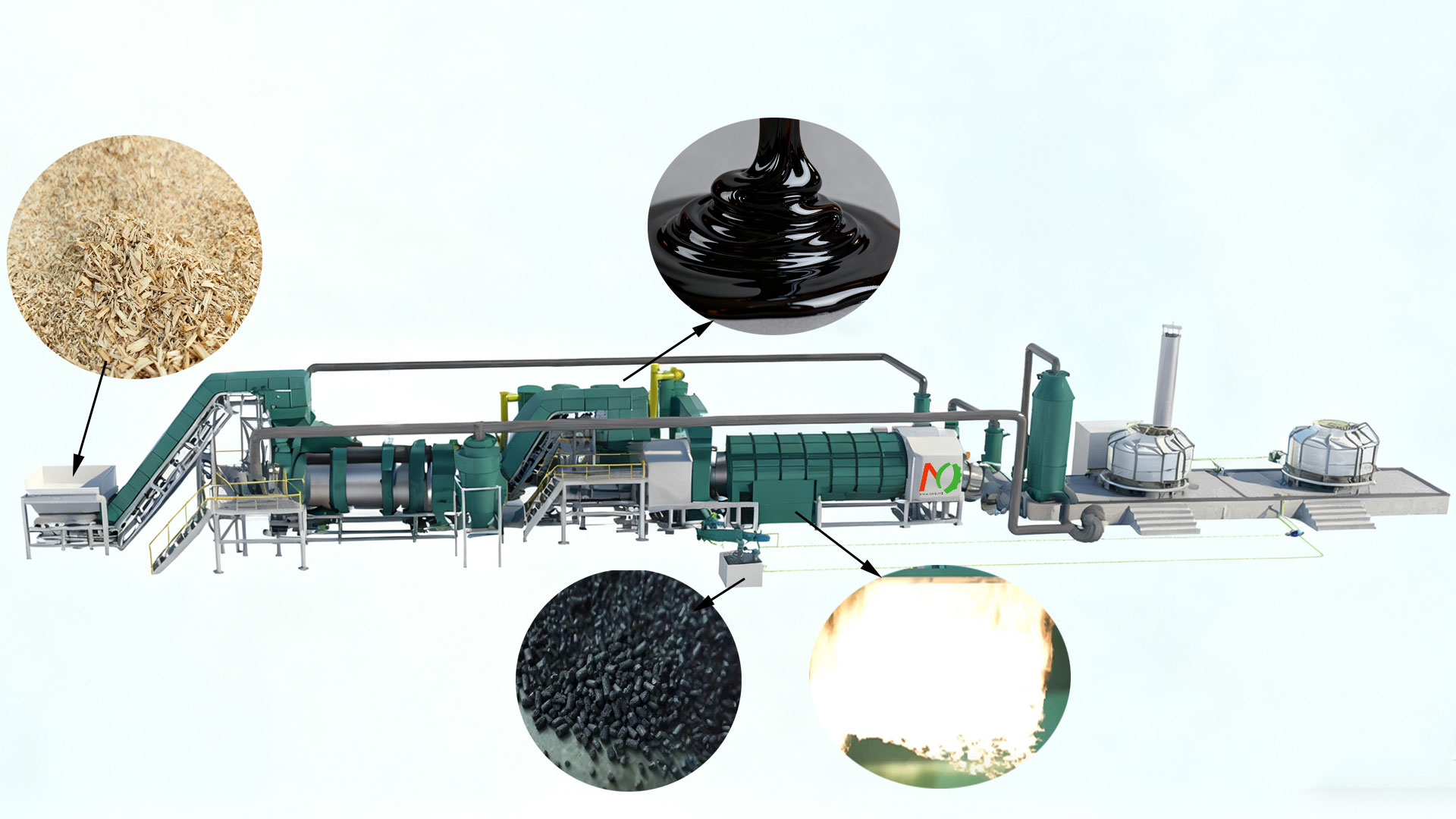

Wood chips pyrolysis machine can convert wood processing residues into high-value-added biochar. It shows broad application prospects in energy supply, soil improvement, and environmental pollution control.

Wood chips, as one of the main wastes generated by the forestry and wood processing industries. They have long been mostly incinerated or discarded, causing resource waste and environmental pollution. The emergence of pyrolysis technology has given waste wood chips a new possibility for high-value utilization. Through a controllable thermochemical conversion process, pyrolysis machine transforms wood chips into various high-value products, such as biochar, bio-oil, and syngas.

Wood Chips Pyrolysis Products

The three types of wood chips biomass pyrolysis products have different physicochemical properties. They exhibit diverse application value in energy, agriculture, and the environment.

Biochar

Biochar is a solid product of wood chips pyrolysis. It possesses a high specific surface area, abundant porous structure, stable carbon structure, and strong adsorption capacity. Biochar can be used as a soil conditioner, adsorbent, and fuel.

Soil Conditioner: Applying biochar to soil increases soil porosity, improves soil aeration and water retention. Simultaneously, the biochar can adsorb heavy metals and organic pollutants in the soil, thereby reducing their bioavailability and crop absorption. Furthermore, the stable carbon in biochar can remain in the soil for a long time, playing a role in carbon sequestration and emission reduction.

Adsorption materials: Utilizing the high adsorption properties of biochar, it can be used in wastewater and waste gas treatment. Compared with activated carbon, biochar has lower production costs and more readily available raw materials.

Energy carrier: The calorific value of biochar is approximately 20-25 MJ/kg (close to that of coal). It can be used directly as a solid fuel or mixed with coal for combustion, reducing the consumption of fossil fuels.

Bio-oil

Bio-oil is a dark brown liquid product of wood chips pyrolysis. It is characterized by its complex composition, high water content, low calorific value, and poor stability. Its applications require refining or modification.

Energy Applications: Through technologies such as hydrorefining and catalytic cracking, bio-oil can be converted into liquid fuels to replace fossil fuels. In addition, bio-oil can be directly used for heating in industrial boilers or as fuel for power generation equipment.

Chemical Production: Bio-oils contain a large number of high-value organic compounds, such as phenols, aldehydes, ketones, and organic acids. These compounds can be extracted through separation and purification techniques and used in the production of chemical products such as resins, coatings, fragrances, and pharmaceutical intermediates.

Soil Remediation Agents: The phenolic compounds in bio-oils have certain bactericidal and insecticidal effects. After dilution, they can be used as soil remediation agents to improve the structure of soil microbial communities.

Syngas

Syngas is a gaseous product of wood chips pyrolysis, primarily composed of H₂ and CO, with trace amounts of CO₂, CH₄, and N₂. Its applications mainly include:

Energy Applications: Syngas can be used directly as fuel for gas turbine power generation or internal combustion engine propulsion.

Chemical Synthesis: Utilizing the H₂ and CO in syngas, liquid fuels or chemicals can be produced through the Fischer-Tropsch synthesis reaction. Furthermore, syngas can be used to produce ammonia, hydrogen, etc.

Cogeneration: Syngas can be used for combustion heating while simultaneously driving a small generator to produce electricity, achieving combined heat and power (CHP).

Wood chips pyrolysis machines are highly efficient biomass-to-biochar conversion devices. They not only realize the resource utilization of forestry waste but also provide an important way to solve energy crises and environmental problems. The conversion from waste wood chips to biochar creates economic value and brings significant environmental benefits.

Currently, Mingjie wood chips pyrolysis machines have achieved large-scale industrial application. They can process various biomass, such as rice husks, wood chips, straw, coconut shells, palm kernel shells, sugarcane bagasse, and animal manure.

These biochar production equipment have been recognized in several countries, including Saudi Arabia, South Africa, South Korea, Chile, Vietnam, and Tanzania. Some biochar plants have already achieved large-scale production and sales of biochar.