Printed circuit board PCB pyrolysis has environmental advantages, while simultaneously utilizing resources such as metals and resins from waste circuit boards. Pyrolysis technology allows for the large-scale processing of waste circuit boards, reducing secondary pollution while recovering resources.

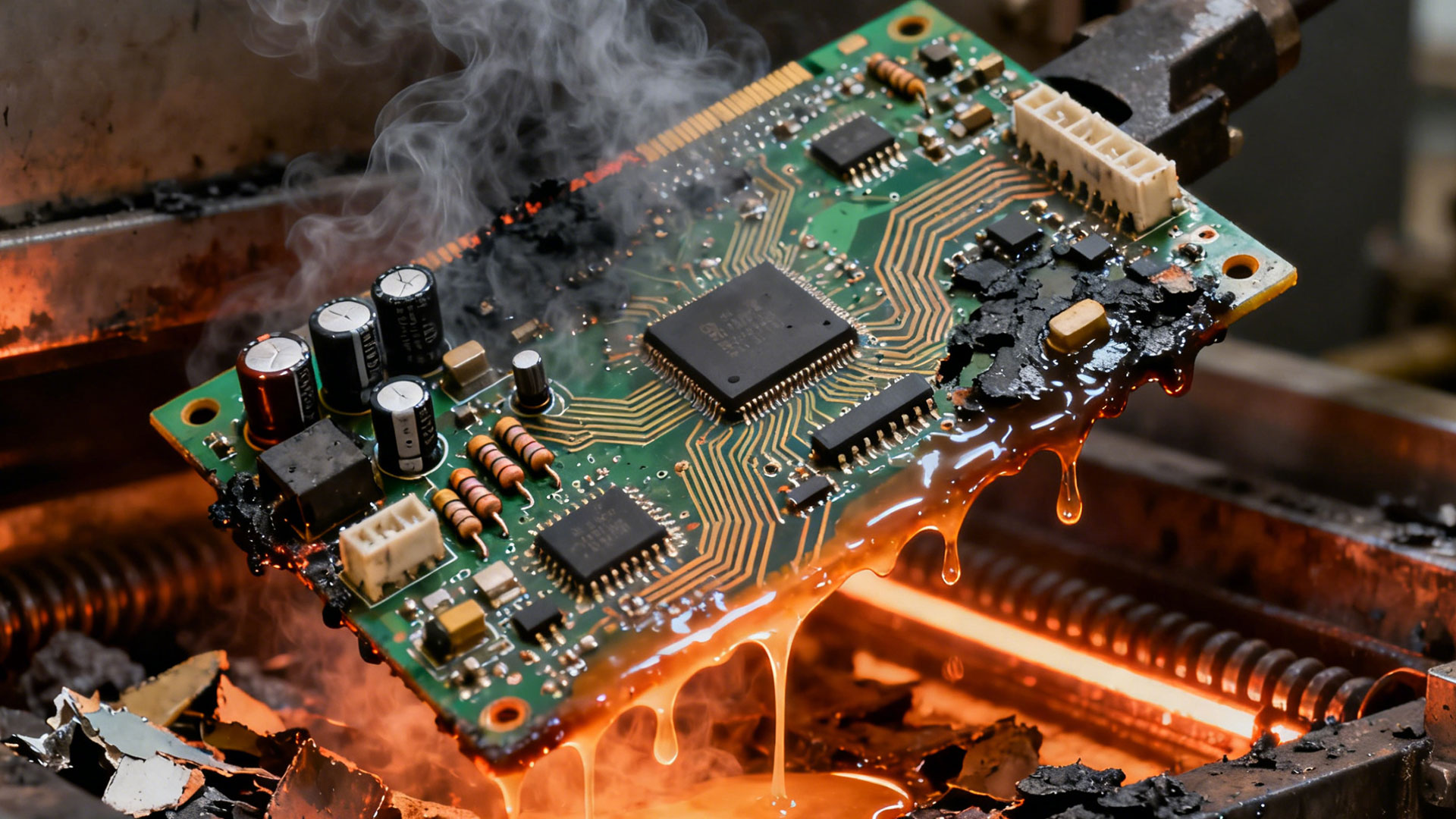

PCB pyrolysis involves heating circuit boards under anaerobic or oxygen-deficient conditions, causing organic polymers to decompose and generate gaseous and liquid products. The pyrolysis oil can be used as fuel or chemical feedstock, while the remaining portion is a mixture of inorganic non-metallic residues and metals.

Continuous pyrolysis system can handle various hazardous wastes, including waste circuit boards and waste resins. It offer significant advantages in energy utilization, energy saving, and emission reduction.

The entire PCB pyrolysis process is automated, ensuring continuous and stable operation. The syngas, after purification and recovery, can be used for heating the pyrolysis equipment. This significantly reduces the consumption of primary resources and mitigates environmental pollution.

Advantages of Waste Printed Circuit Board PCB Pyrolysis

Pyrolysis technology demonstrates significant advantages in the treatment of waste printed circuit boards, particularly in resource recovery and environmental impact.

Highly Efficient Resource Recovery

Pyrolysis technology enables the efficient separation and recovery of various components from waste circuit boards. Research data shows that the distribution of electrical waste pyrolysis products varies among different types of circuit boards.

- Computer circuit board pyrolysis yields 68.9% solid products, 4.7% gaseous products, and 22.7% liquid products.

- Television circuit board pyrolysis yields 60.0% solid products, 6.5% gaseous products, and 28.5% liquid products.

- Mobile phone circuit board pyrolysis yields 82.2% solid products, 2.3% gaseous products, and 15.2% liquid products.

This difference is mainly due to the varying organic matter content in different types of circuit boards.

In the solid residue after PCB pyrolysis, metals are effectively enriched, greatly improving the efficiency and purity of subsequent metal recovery. Experiments have shown that pyrolysis significantly improves the recovery rate of metals such as tin, lead, aluminum, and magnesium. Especially valuable metals like gold and silver from circuit boards can be efficiently recovered through the enriched residue after pyrolysis.

Significant Environmental Advantages

Compared to traditional incineration, PCB pyrolysis technology offers significant advantages in controlling hazardous substances. By conducting thermal decomposition in an anaerobic or oxygen-deficient environment, the pyrolysis process effectively inhibits the formation of highly toxic substances such as dioxins.

Furthermore, researchers have developed a solution to address the issue of pyrolysis byproducts of brominated flame retardants in circuit boards by adding co-pyrolysis agents. Adding co-pyrolysis agents such as zeolite or Fe₃O₄ during pyrolysis effectively fixes bromine. This significantly reduces the content of brominated organic compounds in the liquid-phase products, making phenol and its homologues the main components. Bromine primarily exists in the form of inorganic bromides.

This technological breakthrough greatly reduces the environmental risks of the PCB pyrolysis process and increases the utilization value of pyrolysis products.

Pyrolysis Products of Waste Printed Circuit Boards

The pyrolysis of waste printed circuit boards produces solid, liquid, and gaseous three-phase products. These pyrolysis products have specific utilization pathways.

Pyrolysis Oil

Pyrolysis oil is the main liquid-phase product of waste PCB pyrolysis. It is rich in phenolic compounds, especially phenol and alkylphenols. These phenolic substances are important chemical raw materials and can be used to produce resins, adhesives, and plastics. Through distillation and purification, the purity of phenols in pyrolysis oil can meet industrial raw material standards.

However, the potential presence of brominated organic compounds in pyrolysis oil is a major obstacle to its high-value utilization. Adding a co-pyrolysis agent can significantly reduce the content of brominated organic compounds in pyrolysis oil.

Syngas

Pyrolysis gas mainly consists of H₂, CH₄, CO₂, and CO. It has a certain calorific value and can be used as fuel gas. In the pyrolysis process, the pyrolysis gas is usually collected and purified to provide heat for the pyrolysis process itself. This forms a closed-loop energy utilization, reducing external energy consumption.

For large-scale pyrolysis equipment, excess pyrolysis gas can also be used for power generation. This energy self-sufficiency model significantly improves the economic efficiency and environmental friendliness of the pyrolysis process.

Solid Residue

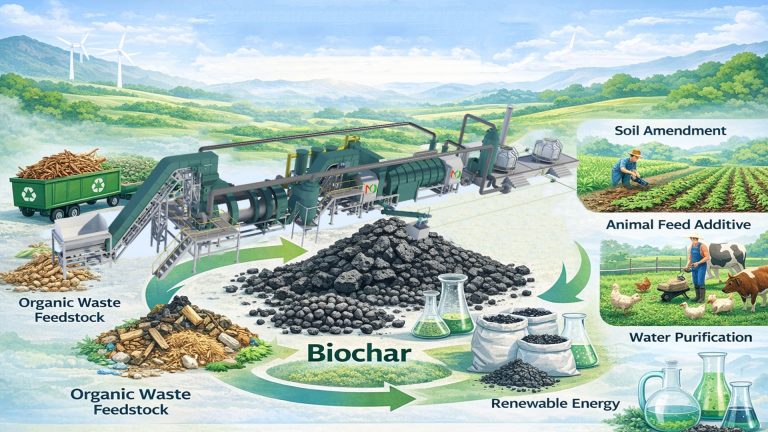

The solid residue after PCB pyrolysis mainly consists of glass fibers, metals, and carbonaceous residue. These solid products have multiple resource recovery pathways.

Metal: The solid residue contains a high concentration of metals, especially copper. Since organic matter has been removed through pyrolysis, the metals are more easily recovered through physical separation methods (magnetic separation).

Glass Fibers: Pyrolyzed glass fibers largely retain their original shape and properties. They can be used as reinforcement in composite materials for the production of low-grade boards or as additives in building materials.

Carbonaceous Slag: The carbonaceous slag produced by pyrolysis has certain adsorption properties. After activation treatment, it can be used as an adsorbent.