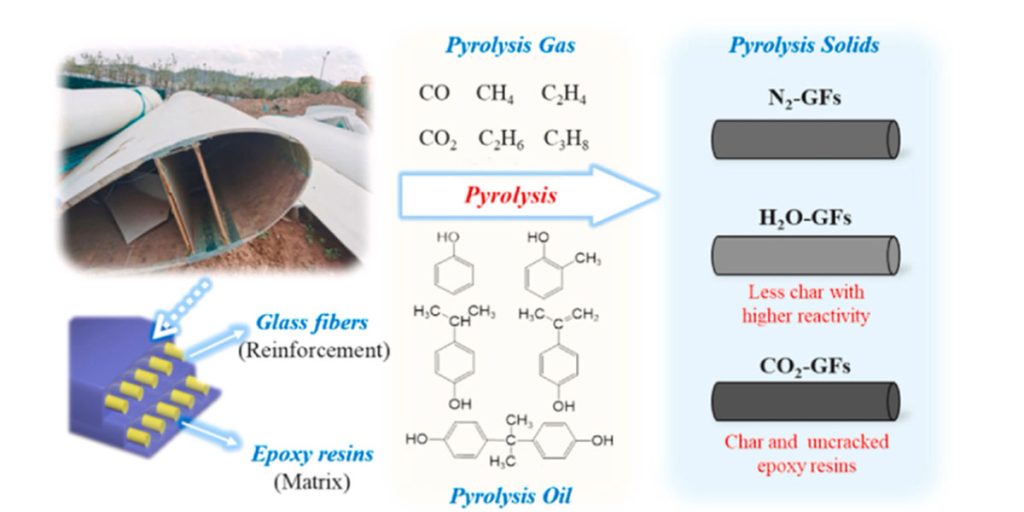

Pyrolysis has emerged as one of the most promising methods for the sustainable treatment of waste wind turbine blades (WWTBs). This is because it effectively recovers high-value products (glass fiber) and generates pyrolysis gas and pyrolysis oil, thereby reducing landfill space waste and harmful emissions. Compared to other end-of-life treatment methods, waste wind turbine blade pyrolysis requires significantly less energy.

Traditional landfill and incineration methods are limited by resource waste and environmental pollution. While purely mechanical processing is environmentally friendly, it reduces mechanical performance and loses energy value, while chemical processing raises questions about its economic viability.

Pyrolysis technology can break down and separate polymeric organic matter in WWTBs at high temperatures without producing dioxins. Simultaneously, pyrolysis oil and gas provide energy, and glass fiber and small amounts of metal components can be directly recycled and reused. This method significantly improves the resource utilization rate of WWTBs, avoiding land occupation and environmental pollution.

Pyrolysis of waste wind turbine blade recycling not only improves the processing efficiency of WWTBs but also reduces energy consumption and carbon emissions.

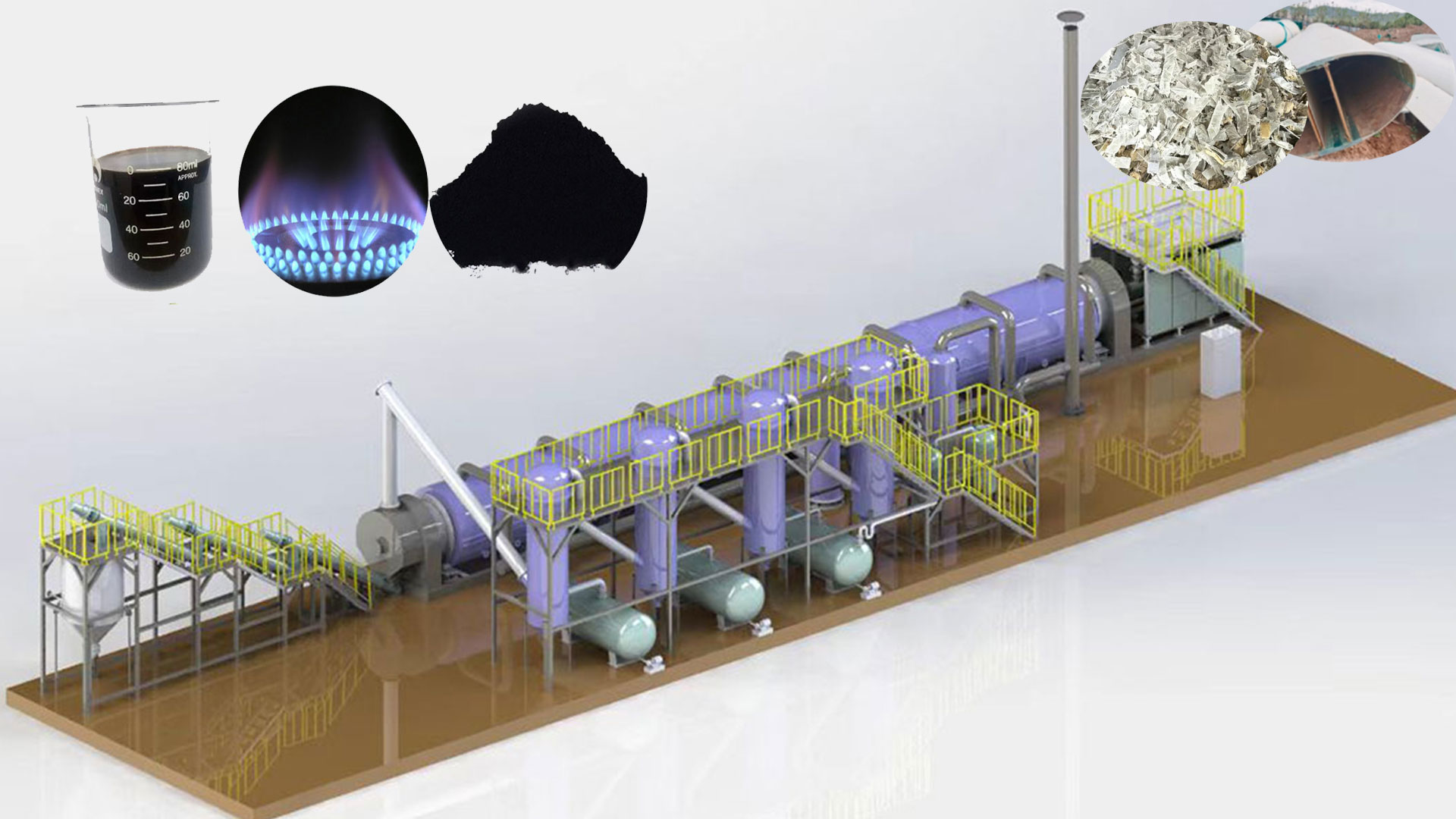

A Tennessee-based company uses pyrolysis system to recover glass fiber from shredded waste wind turbine blades. The company heats the waste wind turbine blades to over 300°C in an anaerobic environment to obtain pyrolysis gas, pyrolysis oil, and glass fiber. The syngas produced by the pyrolysis machine are used as fuel to sustain the pyrolysis reaction, while the liquid fuel can be used in other industrial processes.

Core of Wind Turbine Blade Pyrolysis System

The core of the waste wind turbine blade pyrolysis system is pyrolysis-separation-purification. It breaks the chemical bonds between fibers and resin in the blades, achieving efficient separation of different components.

Pretreatment System

The pretreatment system crushes and dries the waste turbine blades.

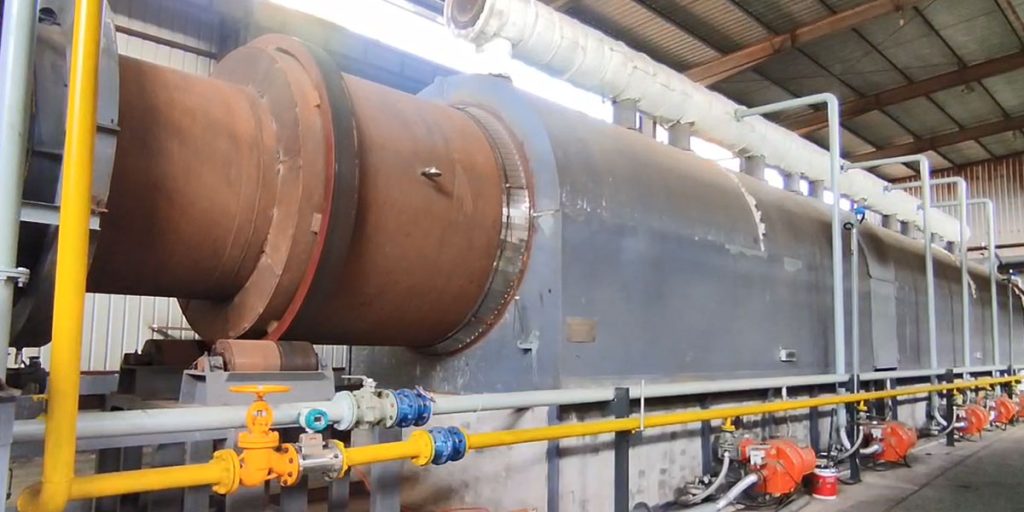

Pyrolysis Reactor

The wind turbine blade pyrolysis reactor is the core of the pyrolysis system. Pyrolysis reactors can be either rotary kiln pyrolysis furnaces or fluidized bed pyrolysis furnaces.

Rotary kiln pyrolysis furnaces are suitable for granular raw materials and offer good temperature uniformity. Fluidized bed pyrolysis furnaces have high thermal efficiency and large throughput. Both require maintaining an oxygen-free environment to prevent fiber oxidation and resin combustion.

- The pyrolysis temperature is 600-700℃. Below 600℃, the resin is not completely decomposed, leaving organic matter on the fiber surface. Above 700℃, the fibers are prone to carbonization, reducing their recycling value.

- The residence time is 30-60 minutes to ensure complete separation of resin and fiber, preventing fiber breakage.

- The heating rate is 5-10℃/min. Slow heating reduces pyrolysis oil cracking and increases the yield of oil phase products.

After waste wind turbine blade pyrolysis, the solid phase products account for 60%-70% (mainly fiber), the liquid phase accounts for 15%-25%, the gas phase accounts for 5%-10%, and the carbon black accounts for 3%-5%.

Pyrolysis Products Separation and Purification

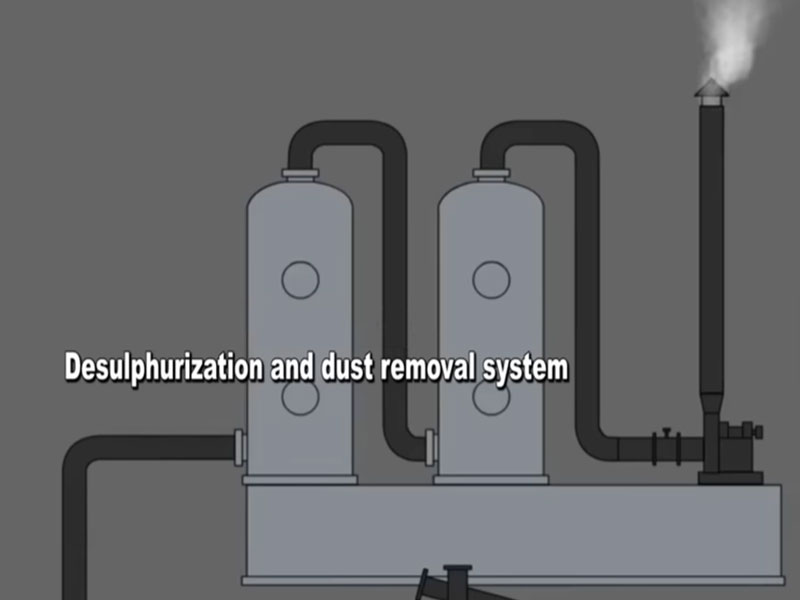

The mixed products discharged from the pyrolysis furnace first pass through a cyclone separator to separate solid fibers and carbon black. Then, a bag filter captures fine fiber dust.

The gaseous products (pyrolysis oil gas + combustible gas) are condensed in a condenser to separate pyrolysis oil and non-condensable gas. The non-condensable gas, after desulfurization and dehydration purification, can be reused for heating the pyrolysis reactor, achieving energy self-sufficiency.

In Summary

the waste wind turbine blade pyrolysis system offers dual benefits of resource recovery and environmentally friendly treatment. It solves the solid waste problem in the wind power industry while creating significant economic value.

With continuous technological advancements and sustained policy support, the pyrolysis system will move from pilot demonstrations to large-scale deployment. It will become a core piece of equipment in the green closed-loop system of the wind power industry.