The MJT-3000 wood biochar production plant has been operational for 5 months since its installation in South Africa was completed. It can process 2500-3000 kg of wood chips per hour and convert them into biochar. The biochar production equipment utilizes continuous pyrolysis technology to fix the carbon in biomass into stable biochar. Simultaneously, it recovers thermal energy and syngas, enabling energy recycling.

Wood Biochar Production Plant Operation Process

Once the installation and preparation of the wood biochar production plant are complete, the wood chip pyrolysis equipment can be started according to the standard operating procedures.

The loading process requires strict control of the loading quantity.

Generally, the loading amount of the pyrolysis reactor should not exceed 80% of its effective volume to ensure sufficient space for heat exchange and reaction during the pyrolysis process. This also prevents overloading from affecting the pyrolysis efficiency. During loading, ensure that the wood chips are evenly distributed in the pyrolysis furnace to prevent localized accumulation.

A conveyor belt transports the wood chips from the silo to the pyrolysis furnace, and a vibrating feeder ensures continuous vibration of the material during transport to prevent blockages.

Starting the heating process is a crucial step in the pyrolysis reaction.

Based on the type of biochar machine and the requirements of the pyrolysis process, the heating temperature and heating rate should be set appropriately. Typically, the initial heating temperature can be set at 100-150°C and maintained for a period to allow sufficient evaporation of moisture from the wood chips. The heating rate during this stage should not be too fast, generally controlled at 5-10°C/min.

After the moisture has evaporated, gradually increase the heating temperature to the required temperature for the pyrolysis stage (200-600°C). At this point, the heating rate can be appropriately increased to 10-20°C/min. During the heating process, closely monitor the operation of the heating system to ensure a uniform temperature increase.

During the pyrolysis reaction stage, the reaction conditions must be strictly controlled.

The reaction time is generally between 1 and 3 hours, it isdepends on factors such as the type of wood chips, particle size, and pyrolysis temperature. During the reaction, ensure that the pyrolysis reactor maintains an oxygen-deficient or low-oxygen environment. Simultaneously, the gaseous and liquid products generated during waste biomass pyrolysis should be collected and processed promptly.

The pyrolysis gas contains combustible gases, which can be transported through pipes to a burner for combustion, providing part of the energy for the biochar equipment. Tar and other liquid products are collected through a condensation device and can be further processed and utilized.

The wood biochar production plant is equipped with a high-efficiency heat exchange system and waste heat transfer pipelines. It can fully utilize the waste heat generated during the carbonization process for preheating and pyrolysis of wood chips. This is of great significance in reducing energy consumption and improving energy utilization efficiency.

The biochar carries a certain amount of heat during the discharge process and is discharged using a water-cooled screw conveyor. This cools the biochar to room temperature before storage or packaging.

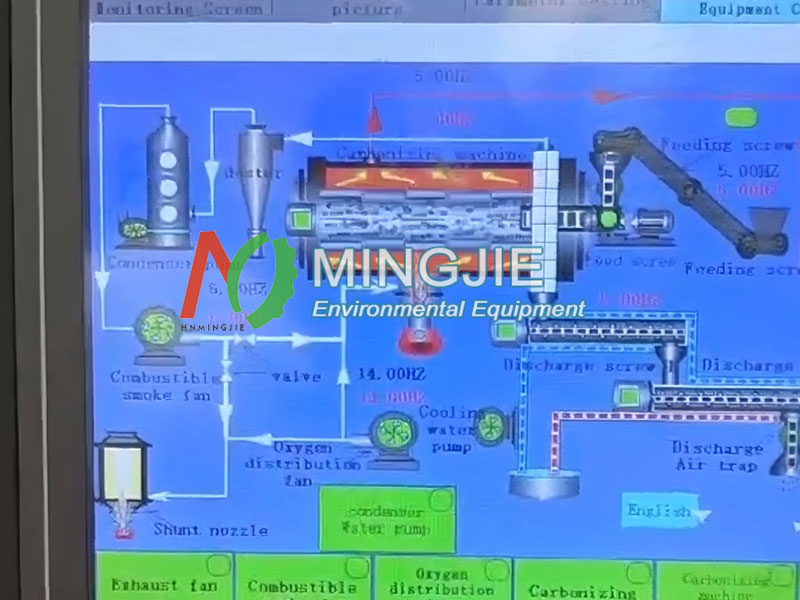

The automated control system enables remote monitoring of wood biochar production plant.

The continuous biomass pyrolysis plant is equipped with an intelligent temperature control system and real-time monitoring devices. This ensures a stable wood chip pyrolysis process and improves the consistency of the biochar product.

Operators can monitor the wood biochar production plant operating status in real time through the monitoring interface, including temperature and pressure changes in the pyrolysis reactor, material conveying status, and the working status of various equipment components. This monitoring function not only facilitates equipment management for operators, but also allows for the timely detection of abnormal operating conditions.

Summarize

Biochar production equipment can convert low-value biomass into high-value products by waste biomass pyrolysis technology. Simultaneously, it achieves carbon sequestration, pollution control, and resource recycling. For investors or users, selecting the appropriate biochar production equipment based on raw material characteristics, production scale, and local policies is crucial to maximizing its economic and environmental value.

The MJT-3000 wood biochar production plant utilizes a continuous pyrolysis reactor, enabling large-scale industrial production with high efficiency. It is ideally suited for solid waste treatment centers or specialized biochar production facilities.