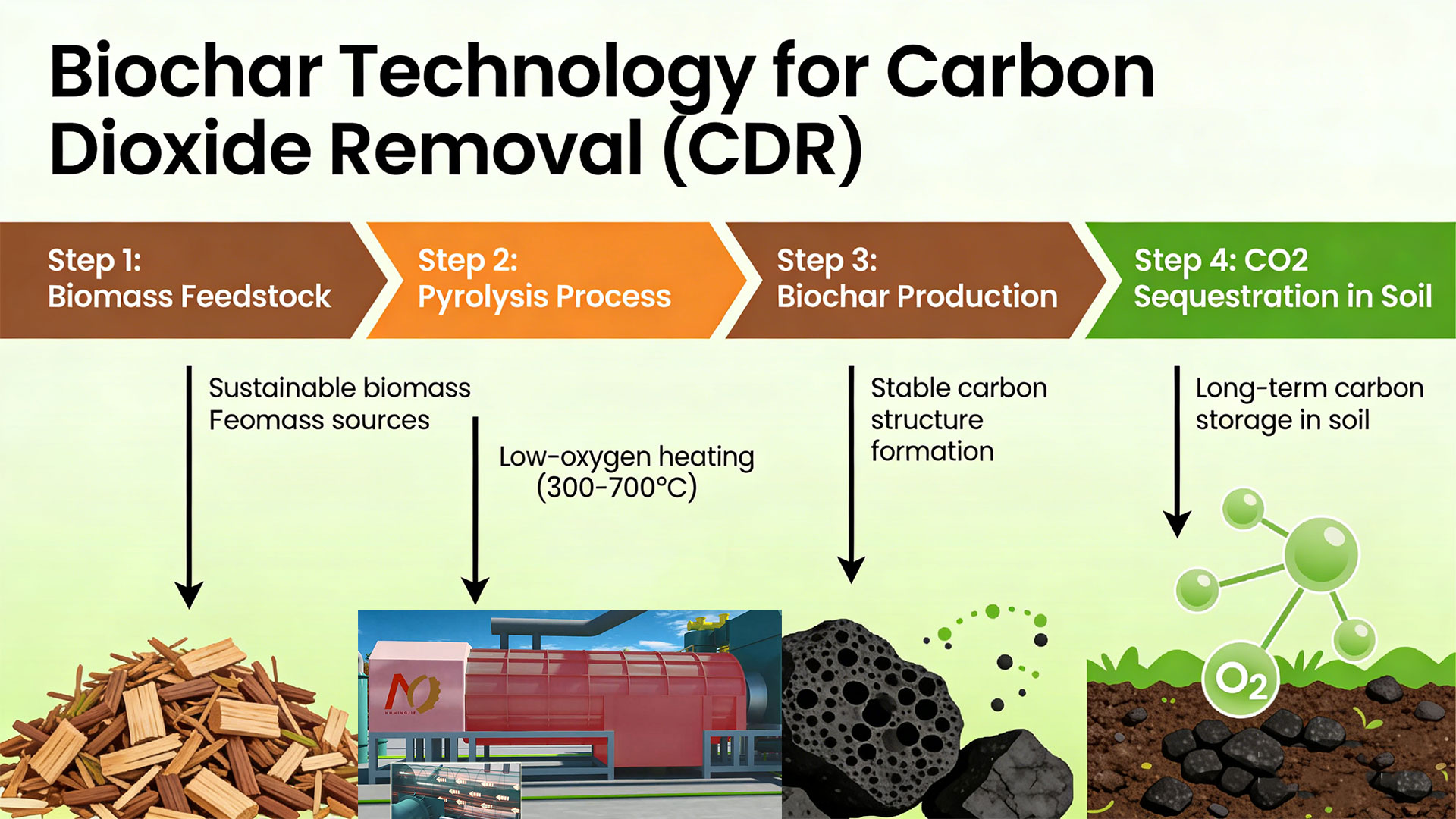

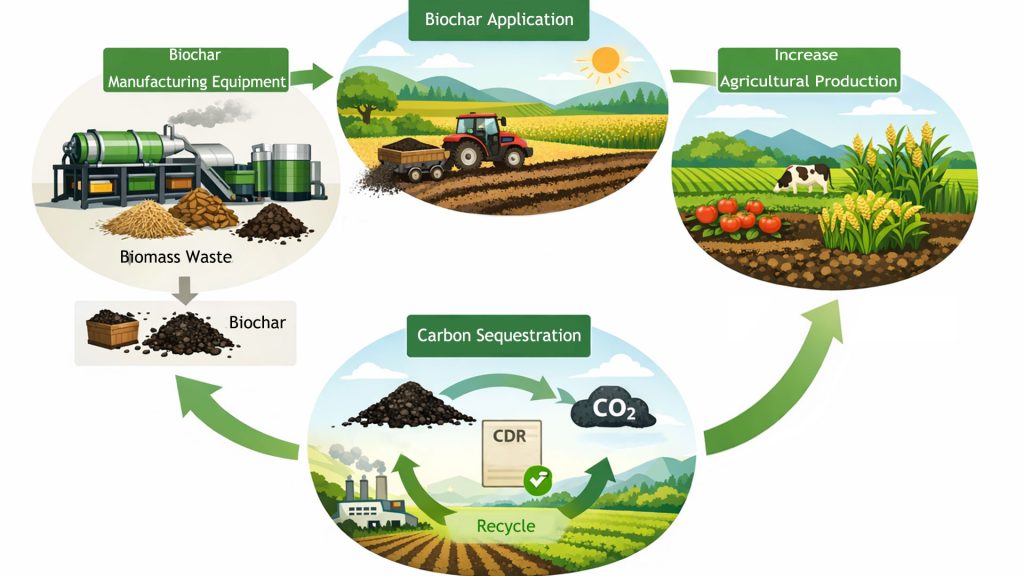

Biochar technology is a process that converts biomass waste (such as crop residues and wood waste) into a stable carbon-based solid material by heating it under oxygen-deficient conditions. This biochar technology was initially used to improve soil health and fertility. However, with the exacerbation of global climate change, biochar has gradually been recognized as an effective long-term carbon sequestration solution.

In early 2026, Microsoft continued to expand its procurement strategy in the field of carbon dioxide removal (CDR). It announced a new biochar carbon removal agreement with the Indian company Varaha. Under this agreement, Microsoft will purchase over 100,000 tons of carbon dioxide removal over the next three years. Through this collaboration, Microsoft not only further accelerates the achievement of its carbon neutrality goals, but also promotes the development of biochar technology in the global carbon market.

Biochar Advantage: Carbon Sequestration Capacity

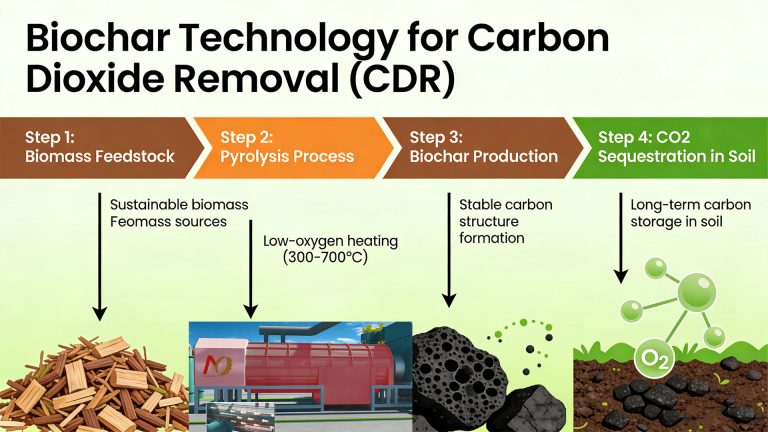

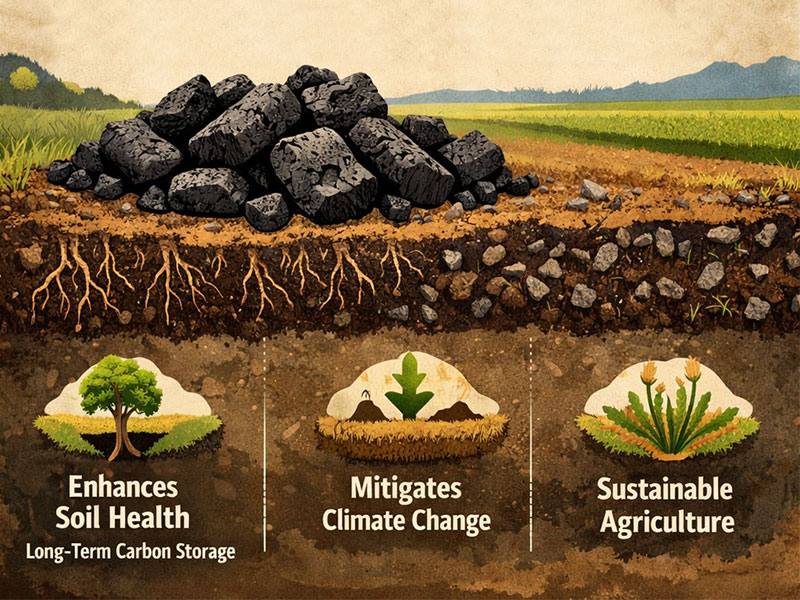

The greatest advantage of biochar lies in its long-term, stable carbon sequestration capacity. Once biochar is added to the soil, it can continuously fix carbon for hundreds of years. This not only reduces the concentration of carbon dioxide in the atmosphere but also improves soil structure and promotes agricultural development.

Compared to other carbon dioxide removal methods, such as afforestation or carbon capture and storage (CCS), biochar production is less expensive. Furthermore, the biomass pyrolysis process is less susceptible to natural disasters or climate change. In addition, biochar technology has a natural connection with agricultural production. It can provide farmers with a source of income while improving soil health.

In recent years, the market demand for biochar technology as a carbon reduction solution has been growing rapidly. Biochar dominates the carbon removal (CDR) market in terms of delivered volume. Mingjie biomass pyrolysis plant has helped several companies achieve continuous biochar production.

- In 2023, biochar contributed approximately 94% of the delivered CDR carbon credits, totaling approximately 1 million tons of CO2 removed.

- In 2025, biochar continued to account for about 90% of the market share, driving the large-scale development of global CDR projects.

Biochar Application for Sustainable Development

Biochar, a carbon-rich material produced through the pyrolysis of organic waste, has emerged as a versatile tool for promoting sustainable urban development. Its key applications demonstrate its potential in various fields, including air quality improvement, waste resource utilization, carbon sequestration, soil remediation, and carbon reduction in the construction industry.

In agricultural soils, biochar promotes carbon sequestration by altering the microenvironment, increasing soil organic carbon, water retention capacity, and microbial abundance. Experimental data shows that biochar characteristics and soil properties jointly influence greenhouse gas reduction. CO₂ reduction is significant in sandy soils, while CH₄ reduction is more effective in clay soils.

The construction industry contributes nearly 40% of global carbon emissions, and biochar is being applied as a cement substitute, aggregate, or road base modifier.

- In cement systems, biochar exhibits good mechanical and adsorption properties due to its internal curing effect and provision of nucleation sites. Carbon storage in biochar-cement composites depends on adsorption capacity, CO₂ diffusion, and carbonation products.

- As an aggregate, biochar replacing 20% of sand can increase flexural strength by 26% and reduce weight by 10%.

- Carbon emissions from biochar concrete decrease with increasing biochar content. At a 5% inclusion rate, CO₂ emissions are reduced by 65.8 kg per cubic meter of concrete, representing a 20.6% reduction.

What Factors Affect Biochar Technology?

Biochar technology is highly dependent on feedstock selection and pyrolysis parameters.

Biomass feedstocks include plant sources (straw, wood), animal sources (manure), and other sources (food waste, sludge). These directly influence the elemental composition and functional group structure of the biochar. Biomass rich in minerals produces biochar with higher nutrient and ash content. Biomass rich in lignin and cellulose, on the other hand, produces biochar with a high aromatic carbon content.

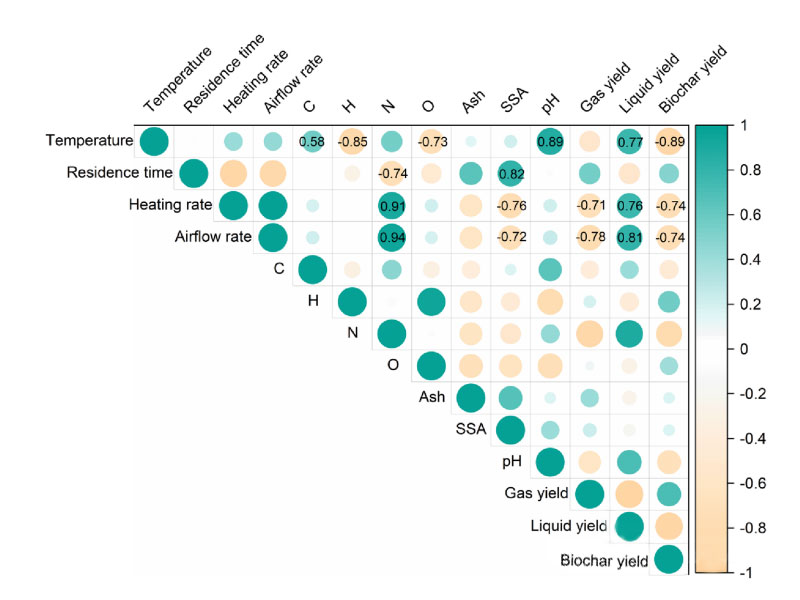

Pyrolysis parameters (heating rate, temperature, residence time, and atmosphere) significantly affect product distribution and biochar characteristics.

Pearson correlation analysis shows that pyrolysis temperature is negatively correlated with biochar yield, but positively correlated with fixed carbon content and pH value. High temperatures promote carbon stability and alkalinity but reduce yield. Residence time is positively correlated with specific surface area (R² = 0.82). Gas flow rate is negatively correlated with gas yield and specific surface area.