Aluminum plastic composite materials are widely used in packaging, construction, electronics, medical, and many other fields due to their excellent properties such as lightweight, moisture resistance, heat insulation, and corrosion resistance. However, they are among the most difficult wastes to recycle. Currently, the most common treatment method is aluminum plastic waste pyrolysis.

These aluminum plastic wastes include aluminum foil bags for food packaging, aluminum-plastic blister packs for pharmaceuticals, aluminum-plastic composite panels for building insulation, and packaging materials for electronic components.

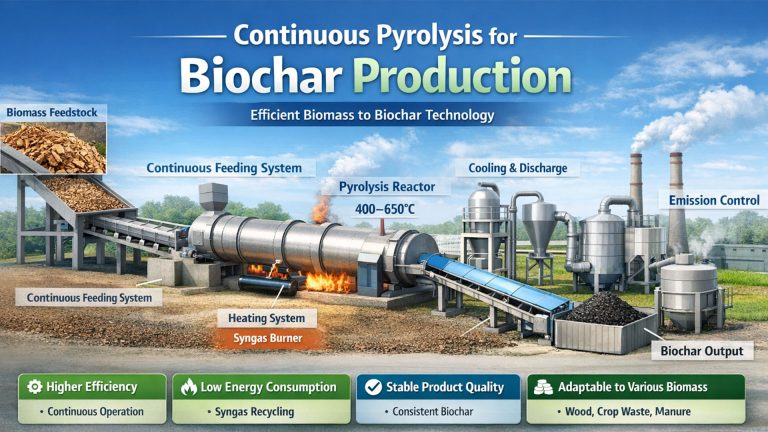

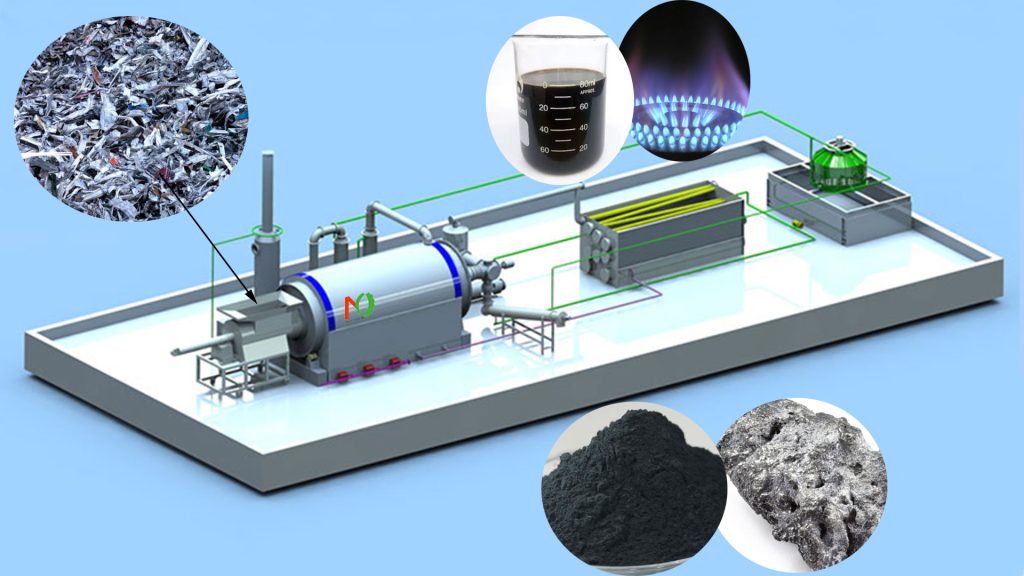

Pyrolysis equipment heats the material at high temperatures (approximately 400–600°C) in an oxygen-free environment, causing the plastic to partially decompose into fuel oil and syngas. The advantage of aluminum plastic waste pyrolysis is that it can simultaneously recover energy and aluminum, with low pollution.

Advantages of Aluminum Plastic Waste Pyrolysis Equipment

Plastic pyrolysis equipment can precisely and efficiently separate aluminum and plastic under safe and environmentally friendly conditions. This not only recovers recycled aluminum with a purity of over 95%, but also reduces the high energy consumption and pollution associated with primary aluminum smelting.

Plastic pyrolysis machine can also convert plastics into fuel oil through pyrolysis, replacing some fossil fuels and realizing the transformation of waste into energy.

Basic Principle of Aluminum Plastic Pyrolysis

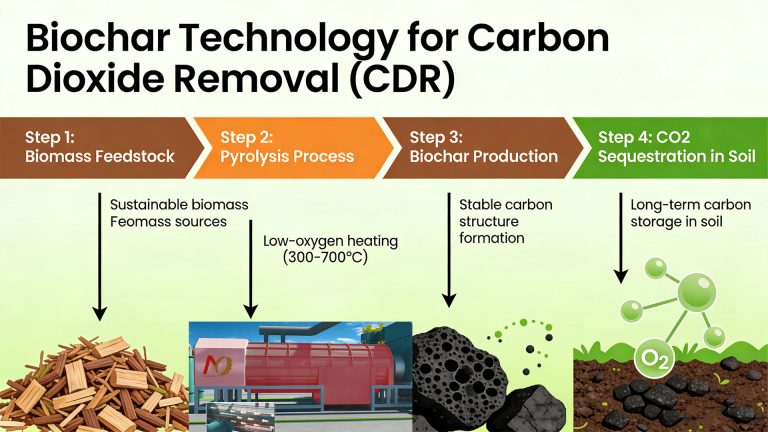

The principle of aluminum plastic waste pyrolysis is to heat aluminum-plastic waste at high temperatures in an oxygen-free or oxygen-deficient environment. This process converts the high molecular weight organic matter into combustible gases, liquid fuels, and coke. Aluminum, with a melting point much higher than that of plastics, remains solid, thus achieving efficient separation of aluminum and plastics.

The core principle utilizes the difference in thermal stability between plastics and aluminum. In an oxygen-free environment at 400℃-600℃, the large molecular chains of plastics break down, gradually decomposing into small-molecule combustible gases, liquid pyrolysis oil, and a small amount of solid char residue. Aluminum, with a melting point of 660℃, remains solid within the normal pyrolysis temperature range and does not undergo chemical changes.

Mingjie pyrolysis plant adopts an environmentally friendly design throughout the entire process, including exhaust gas purification, wastewater recycling, efficient waste recovery, and safe disposal of residue. It ensures that solid waste treatment process meets national emission standards.

Aluminum Plastic Pyrolysis Technology Application

Currently, aluminum plastic waste pyrolysis technology has been industrialized both domestically and internationally.

Europe, America, and Japan have adopted advanced pyrolysis technology and comprehensive recycling systems, forming large-scale, intensive aluminum plastic pyrolysis processing industries.

They emphasize the refined optimization of pyrolysis processes and the high-value utilization of products. Some companies further refine pyrolysis oil into high-end chemical products, increasing the industry’s added value.

In China, multiple provinces have established numerous aluminum plastic waste pyrolysis processing projects, forming mature industrialization models.

The aluminum plastic waste recycling plant includes pretreatment production line, pyrolysis system, a pyrolysis oil refining production line, and a supporting environmental protection system. It achieves an annual processing capacity of 30,000 tons of aluminum plastic waste, producing 15,000 tons of fuel oil and 13,500 tons of aluminum powder annually. The economic and environmental benefits are significant.

Pyrolysis Plant Manufacturer – Mingjie Group

Mingjie Group has developed core equipment, such as continuous pyrolysis equipment and high-efficiency exhaust gas treatment systems. These can effectively reduce aluminum plastic waste pyrolysis equipment investment and operating costs, and improve resource recovery efficiency and product quality.

Mingjie pyrolysis plant is suitable for various aluminum plastic composite materials, solving the problem of poor material adaptability in traditional methods. Whether it’s packaging, construction, electronics, or medical aluminum-plastic waste, efficient processing can be achieved by adjusting pyrolysis parameters.

For infectious aluminum plastic waste in the medical field, the high-temperature pyrolysis process effectively kills pathogens, achieving an inactivation rate of over 99.99%. The closed-loop pyrolysis process avoids the risk of pathogen spread, making it significantly safer than traditional treatment methods.

Modern aluminum plastic waste pyrolysis equipment adopts an automated control system. It can monitor key parameters, such as temperature, pressure, and gas composition in real time. Simultaneously, the equipment is equipped with comprehensive safety protection devices and an emergency response system, ensuring the personal safety of operators and stable production.