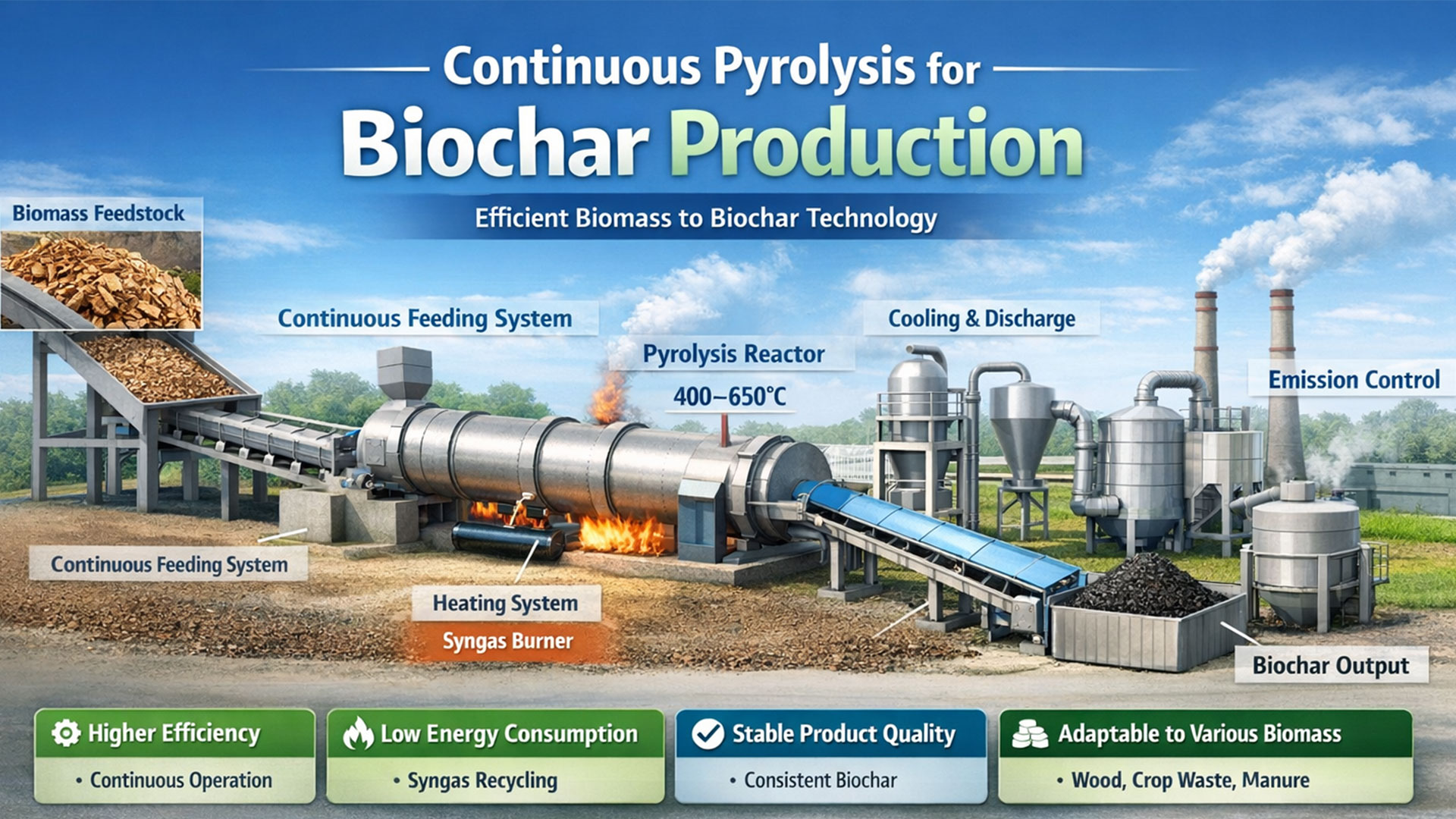

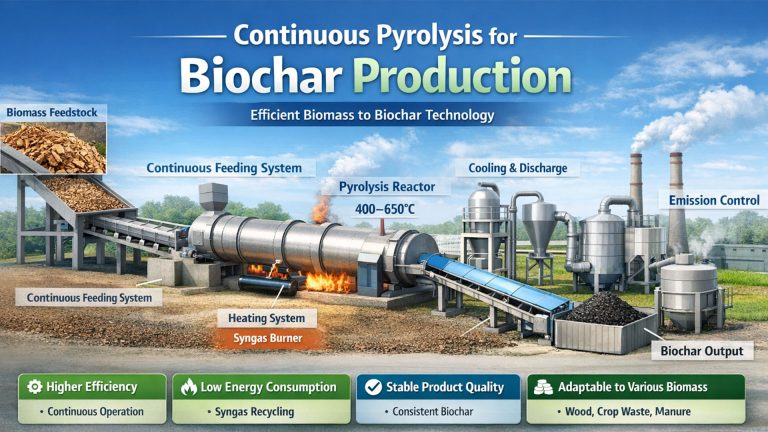

Continuous pyrolysis for biochar production breaks away from the batch pyrolysis model, enabling continuous feeding of biomass raw materials and continuous discharge of biochar. The biochar production line can operate continuously 24 hours a day without interruption. It can process several tons or even tens of tons of biomass raw materials per hour, greatly improving the efficiency of biochar production.

During the continuous pyrolysis of biomass, the operating conditions such as temperature and pressure inside the pyrolysis equipment remain relatively stable. This avoids temperature fluctuations caused by frequent starts and stops, allowing the pyrolysis reaction to proceed under more ideal conditions, thus ensuring a stable supply of biochar. This efficient and stable production process makes continuous pyrolysis technology very suitable for large-scale industrial production needs, meeting the growing market demand for biochar.

Continuous Biomass Pyrolysis Plant for Biochar Production

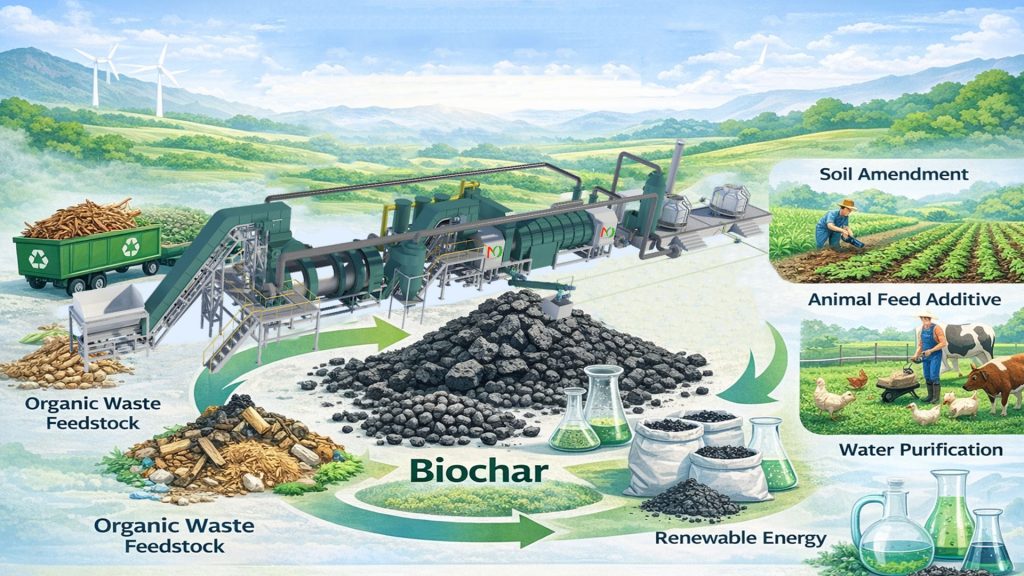

Continuous pyrolysis for biochar production enables the efficient utilization of biomass resources. It converts biomass into various useful products such as biochar, pyrolysis gas, and bio-oil. This avoids biomass waste, facilitates resource recycling, and aligns with the principles of sustainable development.

Mingjie biochar production equipment adopts continuous pyrolysis technology. Through precise control of reaction conditions, it endows biochar with more ideal physicochemical properties, resulting in superior performance in various applications.

During the pyrolysis process, temperature is one of the key factors affecting biochar properties. The continuous biomass pyrolysis equipment is equipped with an advanced temperature control system that can precisely control the pyrolysis temperature within the set range.

Precise control of pyrolysis time also plays a crucial role in improving biochar quality. The continuous biomass pyrolysis equipment can precisely adjust the residence time of biomass in the pyrolysis reactor according to different biomass raw materials and product requirements.

For biomass feedstocks with high lignin content, appropriately extending the pyrolysis time allows for the complete decomposition of lignin. This results in the formation of more aromatic compounds, increasing the stability and adsorption properties of the biochar.

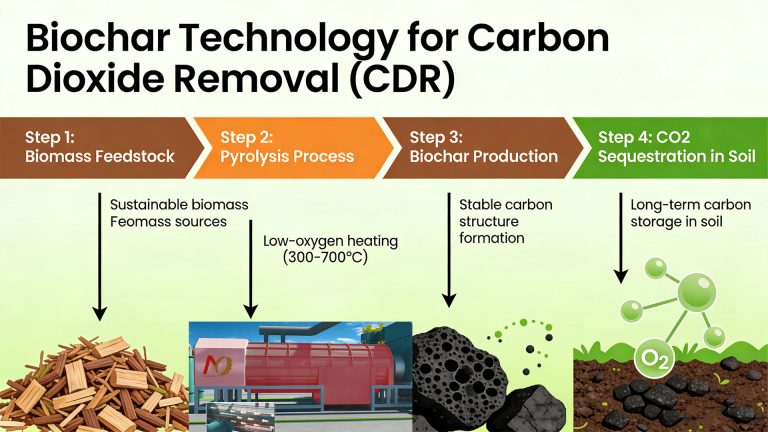

The reaction atmosphere during the continuous biomass pyrolysis process is also strictly controlled, maintaining an oxygen-deficient or low-oxygen environment. This prevents excessive oxidation of the biochar, ensuring its chemical stability.

Through these precise control methods, the biochar produced by the continuous pyrolysis equipment has a more developed pore structure, a higher specific surface area, and more stable chemical properties.

Environmental Benefits of Pyrolysis for Biochar Production

Mingjie continuous pyrolysis plant fully embodies the concept of green environmental protection in its production process, which is of great significance in reducing environmental pollution and promoting the sustainable utilization of resources.

From an energy utilization perspective, the pyrolysis gas generated during the continuous pyrolysis process can be recovered and reused as an energy source. The pyrolysis gas mainly consists of combustible gases such as hydrogen, carbon monoxide, and methane, with a lower heating value of 10-15 MJ/m³.

After purification, this pyrolysis gas can be directly introduced into the combustion system of the pyrolysis furnace, providing heat for the pyrolysis reaction. This achieves energy self-sufficiency, reduces reliance on external fossil fuels, and lowers carbon emissions.

In terms of reducing harmful gas emissions, continuous pyrolysis for biochar production has significant advantages. The biomass pyrolysis process is carried out under oxygen-deficient or low-oxygen conditions, avoiding complete combustion. This reduces the generation of harmful gases such as carbon dioxide, nitrogen oxides, and sulfur dioxide.

Compared with traditional biomass combustion methods, the carbon dioxide emissions from the continuous pyrolysis process can be reduced by more than 50%. And the emissions of nitrogen oxides and sulfur dioxide are also significantly reduced.

Mingjie continuous biomass pyrolysis plant for biochar production is equipped with a highly efficient exhaust gas purification system. It further processes the small amount of harmful gases produced during the pyrolysis process, ensuring that they meet strict environmental emission standards before being released. This effectively reduces pollution to the atmosphere.