Pyrolysis of waste plastics into fuels, a common method of thermochemical conversion, is a popular and promising option in municipal solid waste recycling. Compared to biological recycling, pyrolysis of waste plastics is easier to scale up and can handle unsorted and contaminated waste.

Among numerous thermochemical pathways, pyrolysis has received considerable attention in recent years because it can environmentally friendly convert municipal solid waste into high-value fuels and chemicals.

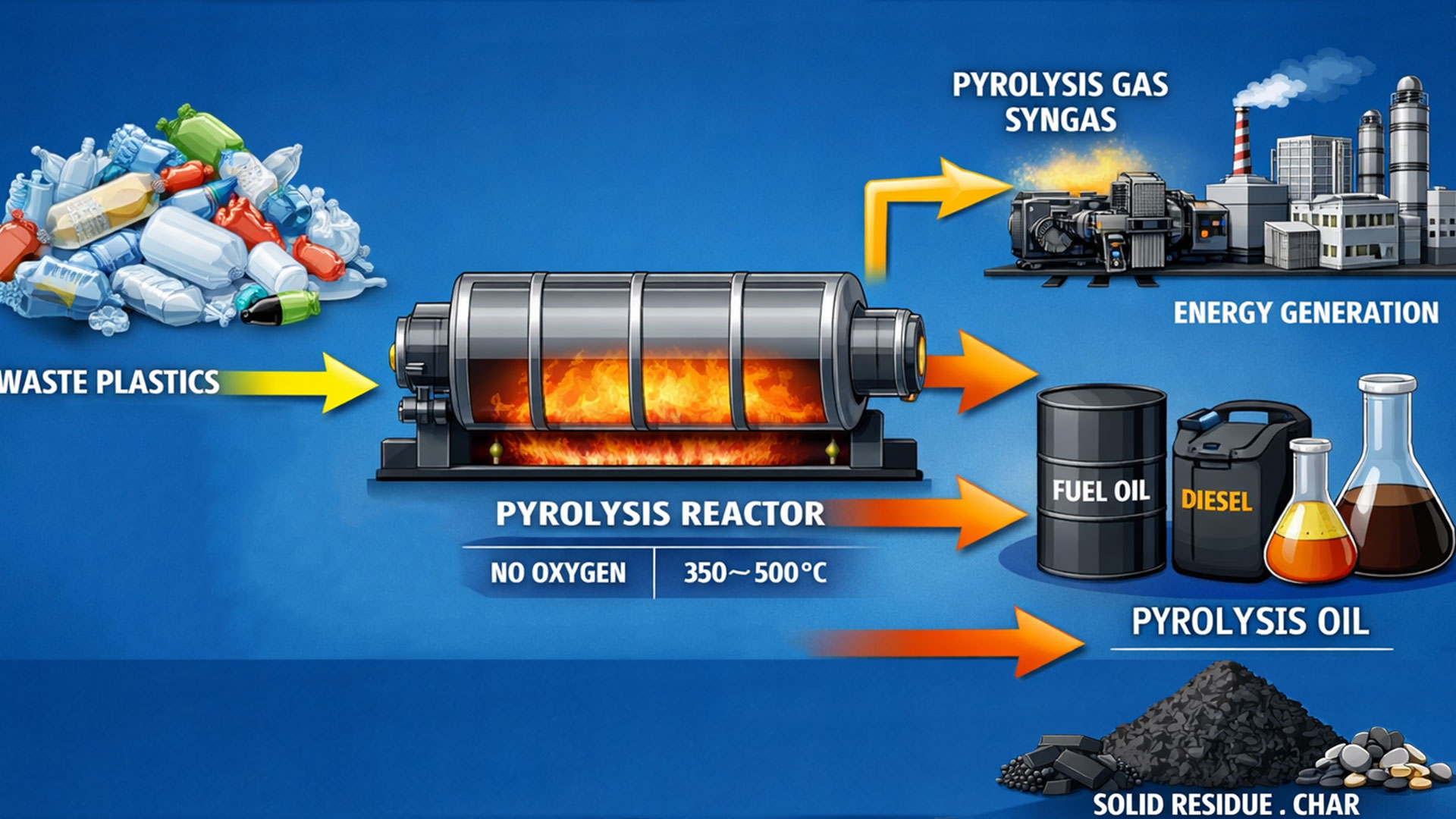

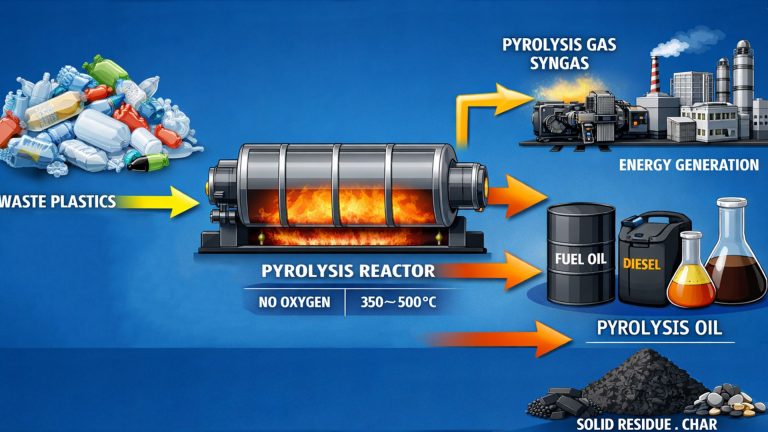

Compared to incineration and gasification, pyrolysis of waste plastics into fuels is carried out under oxygen-free conditions. This reduces carbon dioxide emissions and minimizes the production of toxic pollutants. In particular, under pyrolysis conditions (below 600°C and without oxygen), the emissions of polychlorinated dibenzo-p-dioxins (PCDD) and polychlorinated dibenzofurans (PCDF) can be significantly reduced.

Pyrolysis Plant for Waste Plastics into Fuels

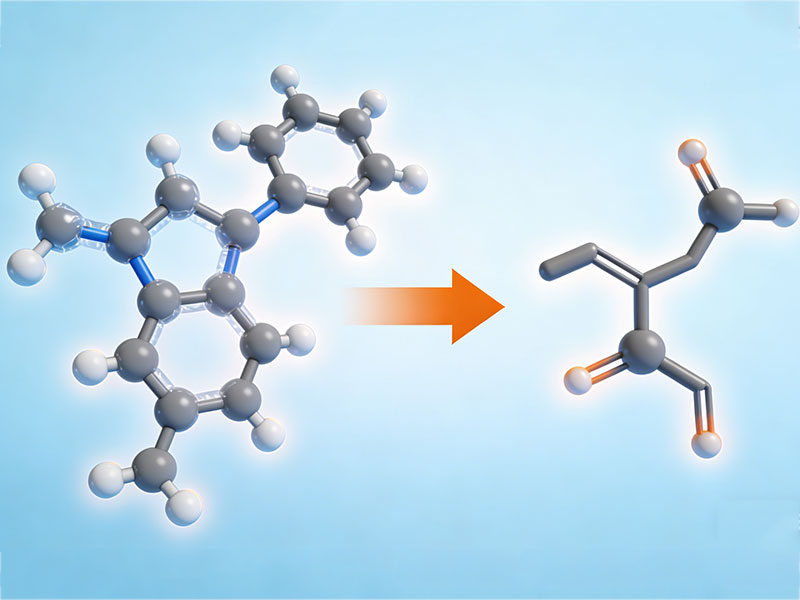

Plastic pyrolysis plant breaks down plastic waste through a complex thermal decomposition process. This process takes place in a sealed pyrolysis reactor under high-temperature, oxygen-free conditions. It breaks down the long-chain polymers in plastics into shorter hydrocarbon molecules, producing a mixture of gas, oil, and char. The oxygen-free environment prevents combustion, allowing for controlled decomposition of the material.

The pyrolysis oil produced from the pyrolysis of waste plastics into fuels is also known as synthetic crude oil. It contains a complex mixture of hydrocarbons similar to those found in petroleum-based products. Its specific composition depends on several factors, including the type of plastic feedstock, temperature, residence time, and reactor design. Generally, polyethylene (PE), polypropylene (PP), and polystyrene (PS) yield the highest quality pyrolysis oil.

Pyrolysis of waste plastics into fuels offers a solution for plastics that cannot be easily recycled using traditional mechanical methods, particularly contaminated mixed plastics.

Converting plastic waste into pyrolysis oil offers multiple environmental benefits. Besides reducing landfill waste, this process also reduces carbon dioxide emissions compared to incineration. When pyrolysis oil replaces virgin fossil resources in plastic production, it creates a circular economy for plastics, significantly lowering the carbon footprint of new plastic products.

Pyrolysis Of Waste Plastics Into Fuels Commercial Applications

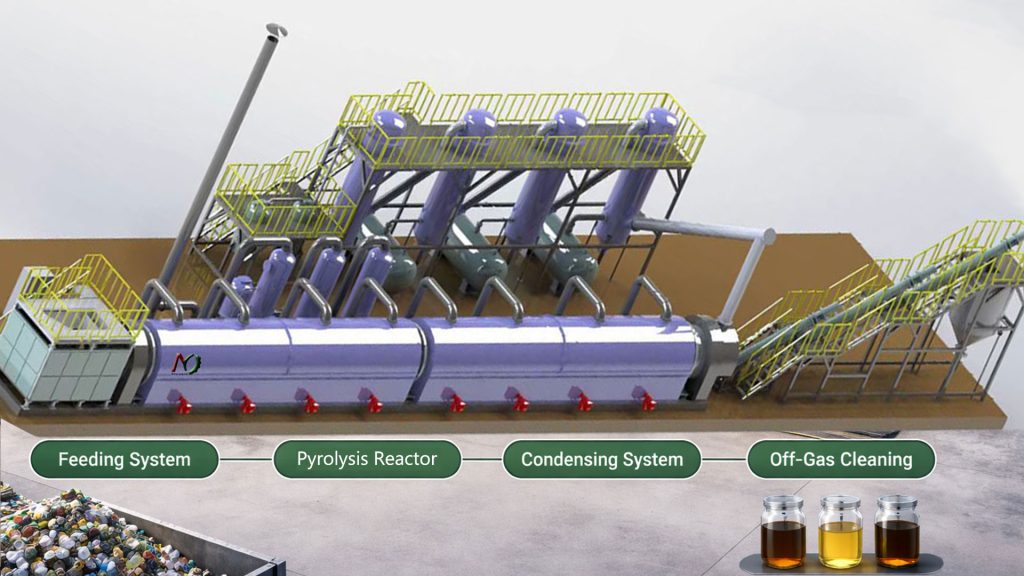

Pyrolysis technology for recycling plastic waste has been commercialized. From pilot-scale experiments conducted in the laboratory to full-scale pyrolysis processes, Mingjie pyrolysis equipment has been used in waste plastic to fuel projects in several countries.

MSW Pyrolysis Of Plastic To Fuel

Pyrolysis can convert municipal solid waste into energy products, and its pyrolysis products typically have properties similar to fuels. The pyrolysis process of municipal solid waste is carried out in a closed pyrolysis plant, which can reduce and eliminate environmental pollution.

In the pyrolysis of municipal solid waste, plastic is one of the most valuable key components that contributes the most to the pyrolysis products (especially high-quality oil). The pyrolysis effect of plastics (especially polyolefins) is very ideal, with high oil yield and good oil quality.

Medical Waste Pyrolysis Of Waste Plastics Into Fuels

Pyrolysis of waste plastics into fuels has received widespread attention in the field of medical waste disposal. It utilizes the thermal instability of organic matter in waste, heating it under oxygen-free or oxygen-deficient conditions. Through a combination of decomposition and condensation, large organic molecules are cracked into smaller compounds, forming high-value energy products such as oil, combustible gas, and solid products with high utilization value.

Unlike municipal solid waste, medical waste contains a large number of bacteria, viruses, and chemical agents, possessing strong infectivity, biological toxicity, and corrosiveness. Pyrolysis equipment can achieve the triple objectives of reducing the volume of organic waste, rendering it harmless, and utilizing resources for high-value products.

Medical waste pyrolysis of waste plastics into fuels can kill pathogens while effectively recovering valuable resources. The exhaust gas emissions contain fewer harmful substances, resulting in less secondary pollution, better control of pollutants, and greater environmental safety.

Compared with incineration, medical waste pyrolysis plant operates at lower temperatures and does not involve open flame combustion. Heavy metals mostly remain in the residue and do not generate catalysts that promote the formation of harmful gases. It allows for the recovery of a large amount of thermal energy, effectively addressing the biggest challenge of medical waste incineration technology.