Market data shows that semi continuous pyrolysis system holds a prominent share in the segmented market of waste tire pyrolysis equipment. According to relevant industry research reports, semi-continuous pyrolysis devices are widely used in waste tire and plastic recycling due to their comprehensive performance advantages. They meet the needs of enterprises of different sizes for waste tire processing.

Many small and medium-sized waste tire recycling and processing enterprises tend to choose semi-continuous pyrolysis equipment. These enterprises typically have relatively small processing scales and limited budgets. The lower initial investment cost and relatively flexible production model of semi-continuous pyrolysis equipment perfectly suit their operational characteristics.

Semi-continuous pyrolysis plant can efficiently process waste tires, converting them into fuel oil and carbon black. This achieves localized resource recycling and also brings considerable economic benefits to enterprises.

Large tire manufacturers and automobile manufacturers also incorporate semi-continuous pyrolysis equipment into their waste tire processing systems. Substandard tires and scrap materials are recycled for their useful components through semi continuous pyrolysis system. This not only reduces waste disposal costs but also achieves secondary resource utilization, improving the green production level of enterprises.

From Asia to Africa, Mingjie semi-continuous pyrolysis equipment operates stably in waste tire processing projects in different regions. This wide range of applications and numerous successful cases strongly confirm the mainstream status of semi continuous pyrolysis system in the industry.

Core Advantages of Semi Continuous Pyrolysis System

Technological Integration

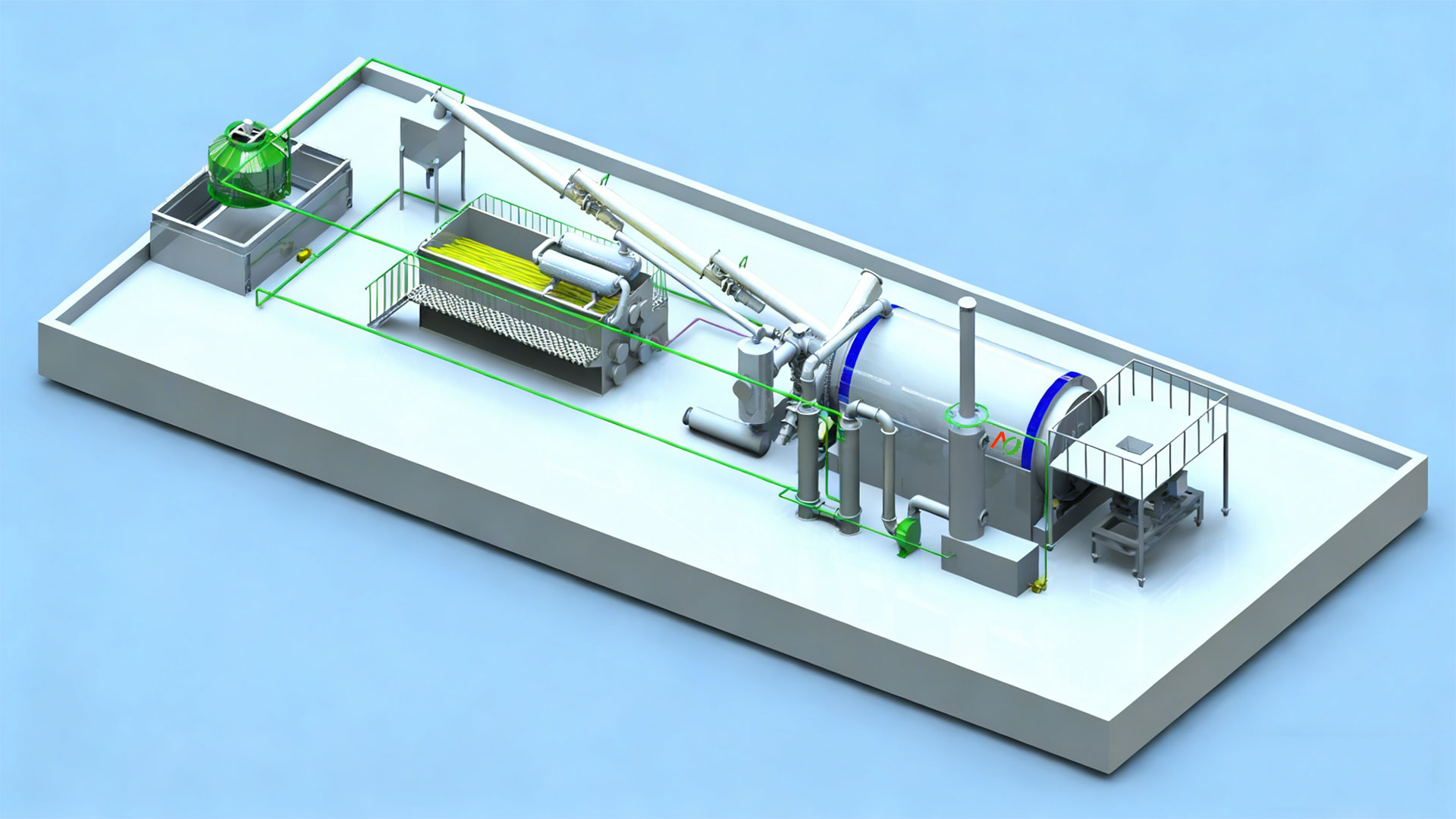

The semi-continuous pyrolysis plant represents a significant innovation at the technological level. It cleverly integrates the core advantages of both batch and continuous pyrolysis equipment, forming a unique and highly efficient technological system.

The semi continuous pyrolysis system cleverly avoids the disadvantages of both batch and fully continuous pyrolysis equipment, while combining their strengths.

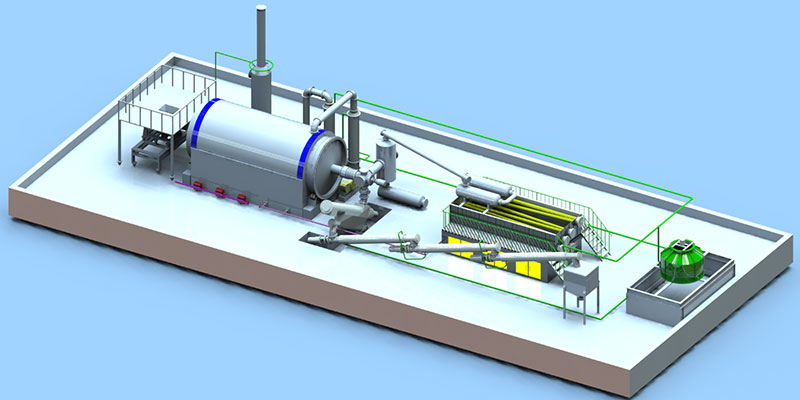

It utilizes the automation technology of continuous equipment in some aspects. The automated feeding system can continuously and stably transport waste tires to the pyrolysis furnace according to a set program, reducing manual intervention and improving feeding efficiency.

In the slag discharge stage, it also draws on the high efficiency of continuous equipment, using a specially designed slag discharge device. This device can quickly and thoroughly discharge the carbon black after pyrolysis, preparing for the next production cycle.

In the core stage of the pyrolysis reaction, the semi-continuous pyrolysis equipment retains the strong adaptability of batch pyrolysis plant to raw materials. It can flexibly process waste tires from various sources and in different conditions.

This technological integration allows the semi-continuous pyrolysis equipment to maintain production efficiency while reducing costs and technical barriers. The semi continuous pyrolysis system has become an ideal choice for many companies in the field of waste tire pyrolysis.

Production Efficiency

The semi continuous pyrolysis system demonstrates exceptional production efficiency, with its automated configuration being a key factor in improving efficiency and production stability.

The automatic feeding system precisely and efficiently feeds waste tires continuously into the pyrolysis reactor. It can adjust the feeding speed and quantity in real time based on the operating status and pyrolysis requirements of the equipment. This prevents decreased production efficiency caused by insufficient or excessive feeding.

The semi-continuous pyrolysis equipment also exhibits unique advantages in the slag discharge process. After the pyrolysis reaction is complete, the resulting carbon black is discharged through a water-cooled screw slag discharge system.

Once the carbon black is emptied, the feeding system can immediately start, feeding new waste tires into the reactor to begin the next batch of pyrolysis production. This “feeding – pyrolysis – slag discharge – re-feeding” cyclical production mode greatly improves the utilization rate and production efficiency of the pyrolysis equipment.

Environmental Protection

The semi-continuous pyrolysis equipment perfectly aligns with the industry’s requirements for green development and has become one of the preferred pieces of equipment in the waste tire pyrolysis industry. Environmental factors were fully considered in the design of the semi continuous pyrolysis system, and it is equipped with a series of effective environmental protection components.

The slag discharge system adopts a sealed design, ensuring that carbon black does not generate dust during discharge, preventing air pollution from dust.