Small scale biochar production equipment is a compact device specifically designed and manufactured for small-scale production needs. It uses agricultural and forestry waste as its main raw material source, such as straw, wood chips, and fruit shells. Through a continuous pyrolysis process within the small scale biochar production equipment, these waste materials are transformed into biochar.

Mingjie small scale biochar production equipment features a skid-mounted design for easy mobility. Its simple and practical design makes it a valuable asset in small-scale biochar production scenarios.

Structurally, it mainly consists of key components such as a feeding system, reactor, heating system, slag discharge system, and purification system. In terms of production mode, it utilizes a continuous pyrolysis process.

The reactor furnace body is typically made of durable metal materials, such as stainless steel or carbon steel. It possesses excellent high-temperature resistance and corrosion resistance, enabling it to withstand the harsh environment of the high-temperature pyrolysis process.

Comparison of Large Scale and Small Scale Biochar Production Equipment

Compared to large scale industrial carbonization equipment, small scale biochar production equipment has distinct differences.

Large scale pyrolysis equipment is often massive, requiring specially planned and constructed large factory buildings for housing. Small-scale equipment, on the other hand, is compact and occupies a small footprint.

In terms of investment, large-scale biomass carbonization equipment requires millions or even tens of millions of dollars in capital investment. It also requires a professional technical team for operation and maintenance. Small biomass pyrolysis equipment has a lower investment threshold, typically ranging from tens of thousands to hundreds of thousands of dollars, making it affordable for small business operators.

Operationally, large scale carbonization equipment has complex processes that require professional personnel to undergo extensive training to master. However, small scale biochar production equipment simplifies the operation process, allowing for easy use after simple training, thus achieving convenient operation.

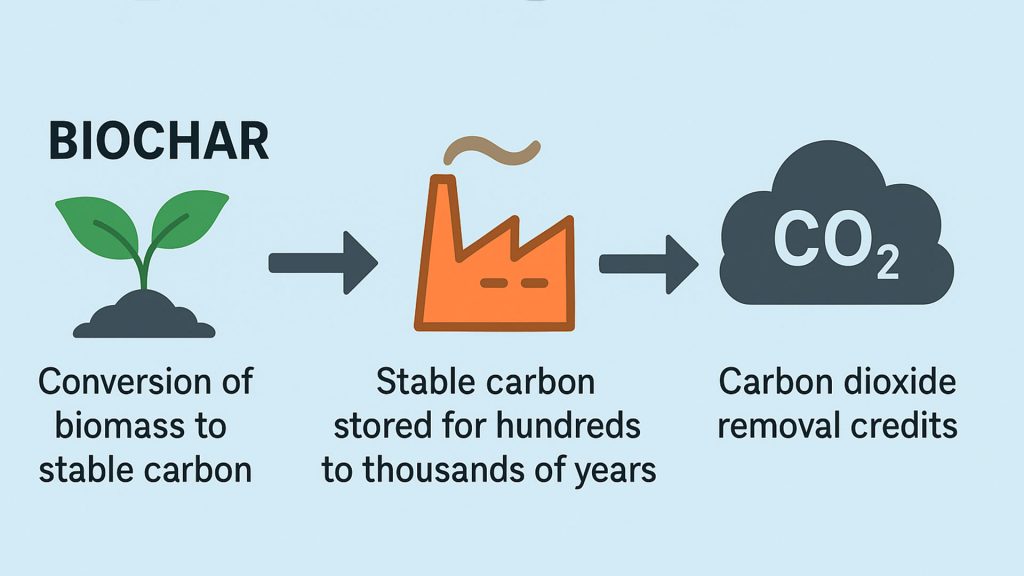

Biochar Production Equipment for CDR Projects

Biochar produced by small scale biomass pyrolysis equipment can be used for soil carbon sequestration. The small scale biochar production equipment may not have the comprehensive data monitoring capabilities of large scale biochar plant, its mobility allows for carbon sequestration projects to be conducted in multiple dispersed locations. It offers a flexible way to participate in the carbon credit market.

Biochar production equipment is a key component in achieving biochar-based carbon sequestration in Carbon Dioxide Removal (CDR) projects. The equipment used in CDR projects must meet the core requirements of “measurability, reportability, and verifiability (MRV)” for CDR projects. It must also ensure high carbon sequestration efficiency, low secondary carbon emissions, and stable product quality.

CDR Project Requirements for Biochar Production

Qualified biochar production activities involve converting waste biomass into biochar through oxygen-deficient/anaerobic processes such as pyrolysis or gasification. The process requires minimizing methane emissions from pyrolysis to extremely low levels. The stability of the biochar material is assessed based on the molar ratio of hydrogen to organic carbon. Materials with a (H/Corg) ratio less than 0.2 are classified as difficult to decompose in the environment.

The raw materials for biochar must come from sustainably sourced biomass or waste biomass. Biochar can only be used in carbon storage applications, such as soil improvement and wastewater treatment. Its use as a fuel or reducing agent is prohibited.

Fossil fuels may be used in the biochar production process. The pyrolysis gas produced during the process should be burned or recovered to avoid methane emissions. The H/Corg ratio of the biochar product must be less than 0.7.

The entire value chain should undergo a life cycle assessment (LCA) according to ISO 14040/44 standards, demonstrating net negative emissions throughout the entire process. The biochar production process must also comply with relevant international and local environmental protection and safety regulations.