Palm oil processing plants in Southeast Asia are mostly located in remote rural areas with insufficient power supply. Palm kernel shells, a readily available waste product in the region, can be converted into energy through pyrolysis technology, effectively addressing local energy supply problems. Compared to other biomass pyrolysis processes, palm kernel shell pyrolysis has significant advantages in terms of raw materials: concentrated production and low collection costs.

Currently, palm kernel shell pyrolysis technology has developed into a major niche market within the biomass pyrolysis field, with Southeast Asia at its core. During the pyrolysis process, palm kernel shells are gradually converted into three core products: bio-oil, syngas, and palm kernel shell biochar.

With the application of large-scale biomass pyrolysis plant, the quality of palm kernel shell pyrolysis products is continuously improving, and palm kernel shell biochar production cost is gradually decreasing.

Palm Kernel Shell Pyrolysis Application

In terms of application areas, the energy sector (pyrolysis gas used for heating and power generation) is the main application area for palm kernel shell pyrolysis technology. Applications in agriculture and soil (palm kernel shell char for soil improvement) and environmental protection are gradually increasing, becoming new drivers of market growth.

Pyrolyzing palm kernel shells into biochar is a sustainable solution. It reduces environmental impact while producing high-value products.

Research shows that the optimal conditions for biochar production are slow pyrolysis (400–600°C, residence time 30–90 minutes), yielding a production rate of 33–52%. Biochar can be applied in soil improvement and agriculture to enhance soil fertility and sequester carbon, and can also be used in air purification and pollutant adsorption, energy and fuel, health and safety, and industrial and material applications.

Compared to incineration and gasification, palm kernel shell (PKS) pyrolysis demonstrates superior environmental sustainability when the biochar is sequestered or used in high-value applications. It offers a dual advantage, meeting current energy demands while contributing to long-term climate change mitigation.

Palm Kernel Shell Pyrolysis Equipment for Biochar Production

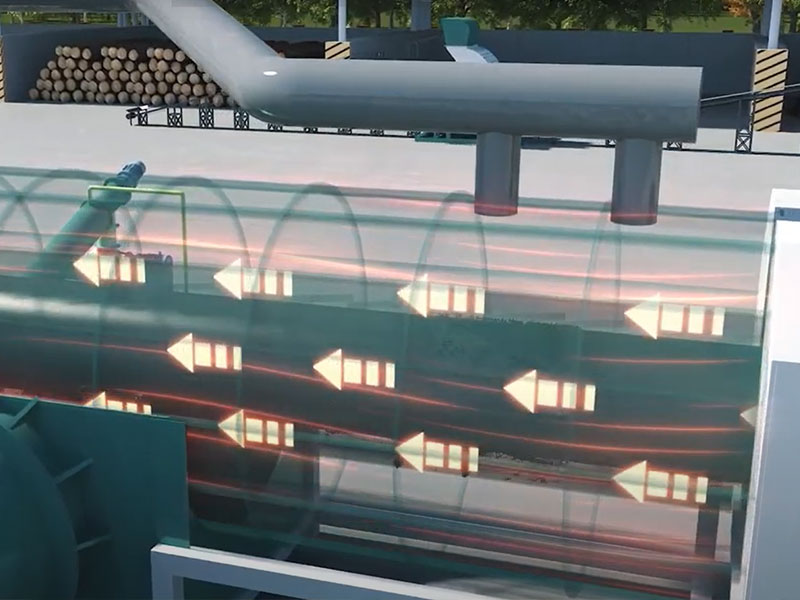

The market demand for continuous palm kernel shell pyrolysis to biochar equipment is growing the fastest. The main reason is that continuous biomass pyrolysis machine offers high production efficiency and is suitable for large-scale biochar production. It can meet the needs of large palm oil companies.

Palm kernel shell biochar is a solid product of palm kernel shell pyrolysis. It is characterized by its high carbon content, porous structure, excellent adsorption properties, and high chemical stability. Palm kernel shell biochar has a carbon content of 75%-85% and a specific surface area of 150-300 m²/g.

The palm kernel shell biochar has broad applications in agriculture and soil science, mainly in soil improvement, carbon sequestration and emission reduction, and as a fertilizer carrier.

Palm Kernel Shell Biochar Application

In soil improvement, palm kernel shell biochar can improve the physical structure of the soil, increasing its aeration and water retention capacity. Palm oil plantations in Southeast Asia often have acidic soils with low fertility and poor water and nutrient retention. Adding palm kernel shell biochar to the soil can adjust soil pH, increase soil organic matter content, and promote the growth and reproduction of soil microorganisms.

In terms of carbon sequestration and emission reduction, palm kernel shell biochar has the ability to sequester carbon for the long term. After palm kernel shells are converted into biochar through pyrolysis, the carbon elements are fixed in the solid product and are difficult to decompose by microorganisms. Palm kernel shell biochar can remain in the soil for hundreds or even thousands of years, thus reducing carbon emissions into the atmosphere and mitigating the greenhouse effect. Southeast Asian countries have applied palm kernel shell biochar to palm oil plantations, not only achieving soil improvement but also contributing to national carbon neutrality goals, which has been recognized by the international community.

As a fertilizer carrier, the porous structure of palm kernel shell biochar can adsorb nutrients from fertilizers, reducing nutrient loss and volatilization, and improving fertilizer utilization efficiency. In addition, palm kernel shell biochar can also be used as a raw material for bio-organic fertilizers, mixed and fermented with livestock manure and crop residues for organic agricultural production.