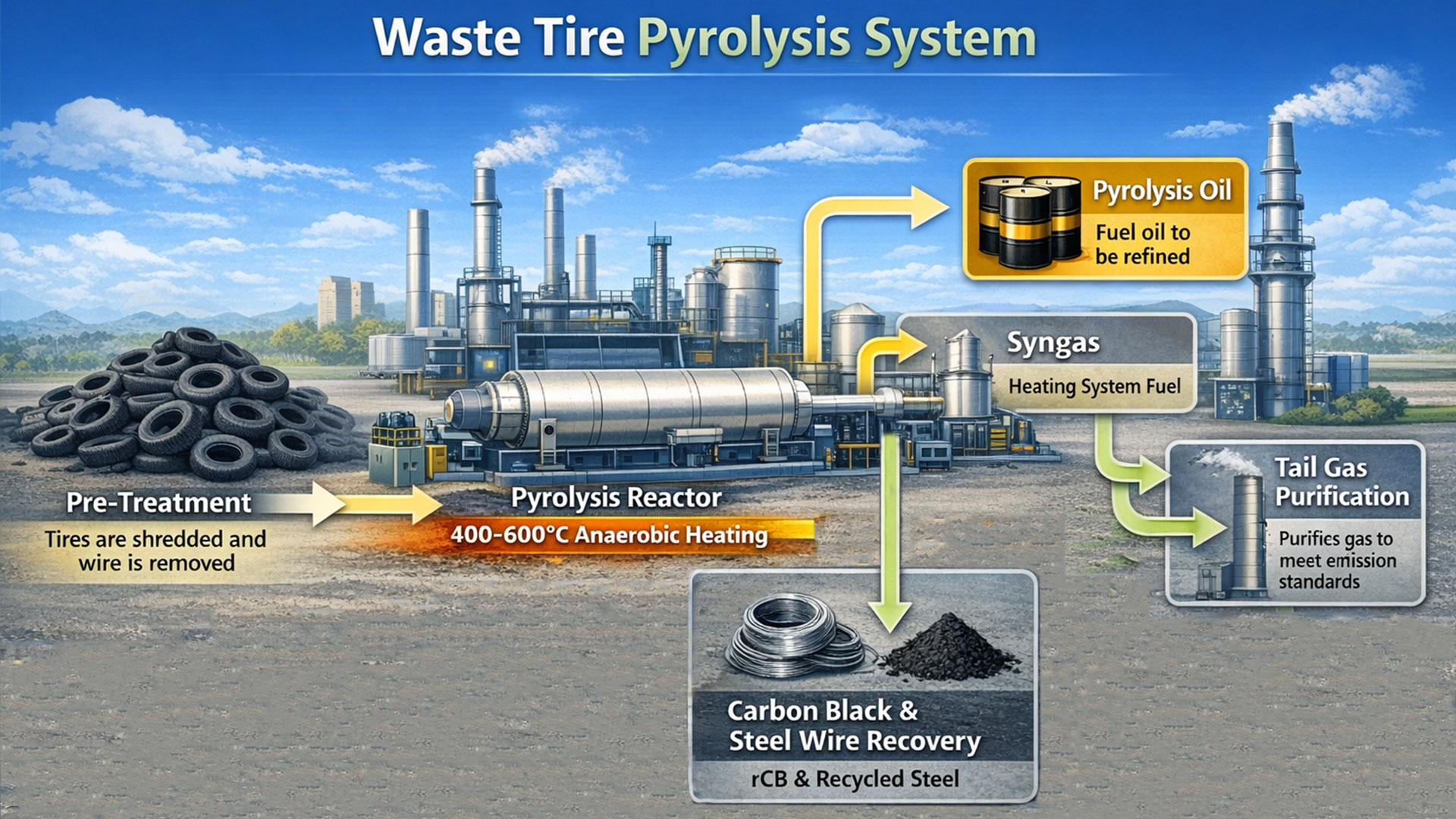

The waste tire pyrolysis system, as a solution to the challenging problem of waste tire disposal, enables the resource utilization of waste tires. Through high-temperature decomposition, waste tires can be converted into various high-value products such as carbon black, pyrolysis oil, synthesis gas, and steel wire. Carbon black can be used in the reprocessing of rubber products, tire pyrolysis oil can be used as industrial fuel, and steel wire becomes a raw material for metal recycling.

Components of Waste Tire Pyrolysis System

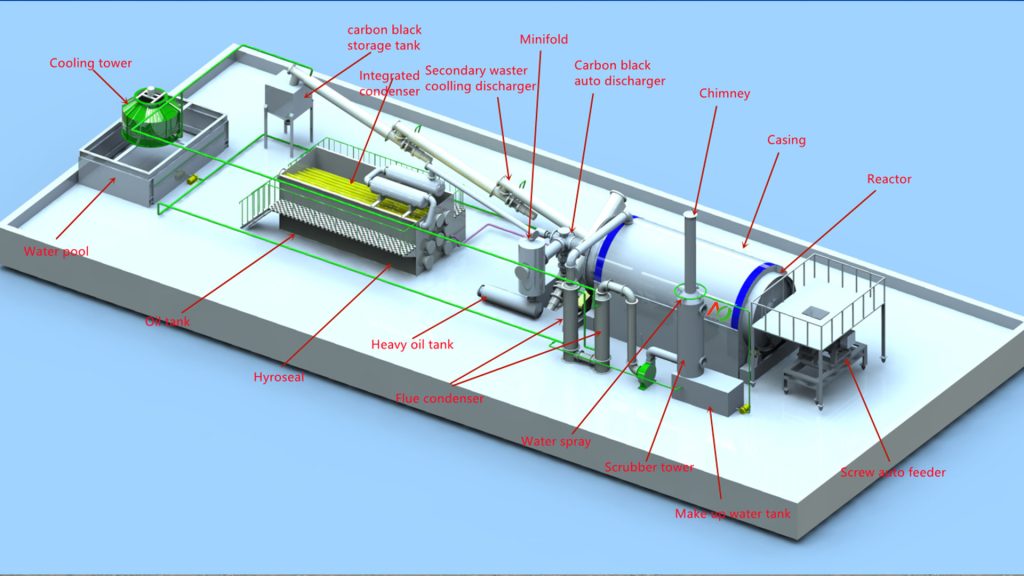

The waste tire pyrolysis system mainly consists of feeding system, a pyrolysis reactor, product separation and exhaust gas treatment equipment.

The pretreatment equipment is crucial for the continuous waste tire pyrolysis system. Multi-stage crushing equipment is the first step, crushing the waste tires into particles of a suitable size for subsequent processing. A magnetic separation and screening device is then used to separate steel wires and other metal impurities from the tires, ensuring the uniformity of the material entering the pyrolysis reactor.

The pyrolysis reactor is the core equipment of the entire waste tire pyrolysis system. A commonly used tire pyrolysis reactor is the rotary kiln. The rotary kiln reactor is an inclined rotating cylinder in which the waste tires move slowly while being heated externally.

Inside the pyrolysis reactor, the tires undergo pyrolysis in a high-temperature, oxygen-deficient environment, producing pyrolysis gas, pyrolysis oil, and carbon black. The advantage of the rotary kiln is its strong continuous pyrolysis capacity. The waste tires have a uniform residence time in the kiln, ensuring the stable progress of the pyrolysis reaction.

In the product separation stage, a condensation system is used to cool the condensable gases in the pyrolysis gas into liquid, achieving the recovery of pyrolysis oil. A water-cooled screw slag discharge system discharges the carbon black from the pyrolysis reactor. The carbon black discharge process is fully automatic, clean, and pollution-free.

In addition, an exhaust gas treatment system can purify the flue gas produced during the pyrolysis process. Harmful substances are removed to meet environmental emission standards before discharge.

Applications of Waste Tire Pyrolysis Products

Tire and Rubber Products Sector

In the tire and rubber products sector, the products of waste tire pyrolysis systems play a crucial role, providing strong support for the sustainable development of the industry. The carbon black produced by pyrolysis can be used as an important raw material for rubber products, widely applied in the production of tires, rubber seals, conveyor belts, and other products.

In the manufacturing of rubber seals, pyrolysis carbon black also performs exceptionally well. Pyrolysis carbon black has excellent filling and reinforcing properties. It can effectively improve the hardness, tensile strength, and aging resistance of rubber seals, extending their service life.

Pyrolysis oil also plays an important role in the rubber processing process, serving as a softener and plasticizer. It can reduce the viscosity of rubber, improve its processing performance, and increase production efficiency.

Pyrolysis oil can also enhance the interaction between rubber molecules. It can improve the flexibility and elasticity of rubber products, improving the overall performance of the products.

Energy Sector

In the energy sector, the pyrolysis oil produced by waste tire pyrolysis system has significant application value. Tire pyrolysis oil can be directly used as fuel oil for combustion in industrial boilers, heating furnaces, and other equipment, providing thermal energy for industrial production.

Pyrolysis oil can also be used in power generation, converted into electrical energy through modified diesel engines, achieving diversified energy utilization.

Plastics Production

In the plastics production sector, pyrolysis carbon black can be used as a plastic filler to improve the hardness, strength, and wear resistance of plastic products. Adding pyrolysis carbon black to plastic products can effectively improve product performance.

Pyrolysis carbon black can also be used in ink production, improving the quality and stability of the ink.