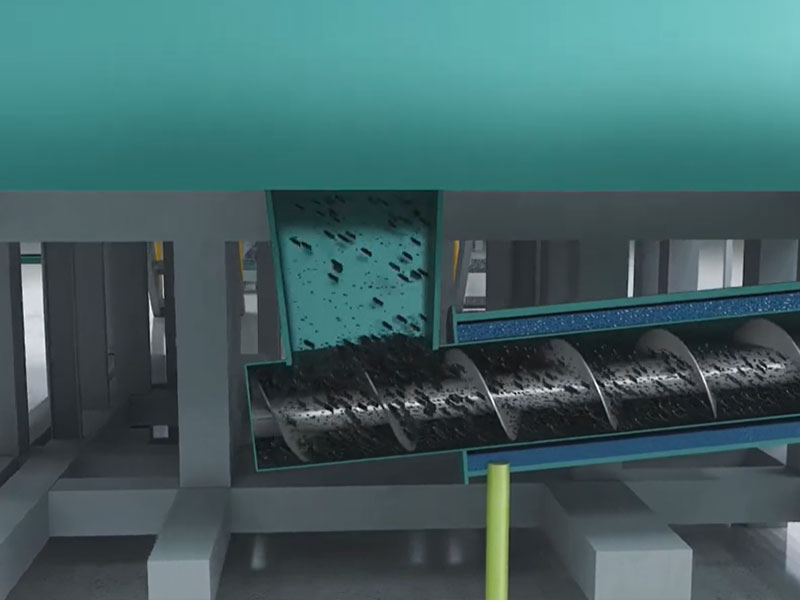

Bio char making machine produces biochar by heating biomass in an oxygen-deficient environment, the process called biomass pyrolysis.

Pyrolysis is a core step in the biochar production process. It involves heating biomass at high temperatures in an oxygen-free or oxygen-deficient environment. During this process, the macromolecular organic matter in the biomass decomposes. As the temperature gradually increases, typically between 300 and 700°C, the biomass undergoes a series of changes.

First, water evaporates rapidly. Next, volatiles begin to precipitate, including a variety of organic compounds such as tar, methane, and hydrogen. The remaining residue gradually carbonizes, forming biochar. Its primary component is carbon, with trace amounts of hydrogen, oxygen, and nitrogen.

Bio char can directly replace coal in industrial applications, including power plants and cement kilns. It can also be used to sequester carbon in soil.

The tar produced by iocoal making machine can be further processed to extract valuable chemical products such as phenols and aromatics. The combustible gas produced can be used as fuel, providing part of the energy required for the biomass pyrolysis process, thus achieving energy recycling.

Advantages of Bio Char Making Machine

Significant Environmental Benefits

Biochar making machine offers significant environmental advantages, significantly reducing emissions compared to traditional coal. Biochar can be effectively used in the production of biocoal as a functional additive to improve the quality of biocoal products.

Traditional coal combustion releases large amounts of greenhouse gases, such as carbon dioxide, sulfur dioxide, and nitrogen oxides, posing a serious threat to the ecological environment and human health.

Relevant research data shows that burning one ton of coal produces approximately 2.5 tons of carbon dioxide emissions. These pollutants are also associated with certain amounts of sulfur dioxide and nitrogen oxides. These pollutants are not only a major factor in global warming but also contribute to a range of environmental problems, such as acid rain and smog.

Biochar produced by bio char making machine is significantly different. Because its raw material is primarily biomass, during its growth process, the biomass absorbs carbon dioxide through photosynthesis and converts it into its own organic matter.

When biocoal is burned, the amount of carbon dioxide released is roughly equivalent to the amount absorbed during its growth. From a lifecycle perspective, biochar combustion achieves near-zero carbon dioxide emissions, significantly reducing its impact on the greenhouse effect.

Widely Available Raw Materials

The raw materials for biochar production equipment come from a wide range of sources, including waste and residues from agriculture, forestry and other sectors.

In the agricultural sector, a large amount of crop straw, including corn straw, wheat straw, and rice straw, serves as high-quality raw material for bio char production. These straws are sent to bio char making machine, where they are processed and transformed into efficient bio charcoal.

Forestry residues are also a key raw material source for bio char making machine. Wood processing generates a large amount of waste, such as sawdust, bark, and scraps. Biochar production equipment can effectively utilize these forestry residues.

Significant Economic Benefits

Bio char making machine offer significant environmental benefits while also possessing enormous economic benefits.

From an energy cost perspective, using biocoal can effectively reduce energy expenses for both businesses and consumers. Biochar produced by bio char making machine can be used as fuel. Biochar prices are relatively stable, and transportation and storage are more convenient. Furthermore, its clean combustion properties reduce reliance on environmental protection equipment and maintenance costs.

The development of the biochar manufacturing industry will also create numerous employment opportunities. These range from collecting and transporting biomass raw materials to operating and maintaining biochar machine, and finally to selling and providing after-sales service for biochar products. The entire industry chain involves numerous links, each requiring a significant workforce.

As a key force in energy transformation, biochar production machines have enormous development potential and broad application prospects. Mingjie Group is a professional manufacturer of biomass carbonization equipment. Our biochar equipment can process a variety of biomass, including coconut shells, palm shells, coffee shells, straw, wood chips, rice husks, bagasse, sludge, etc.