In the industrialized production of biochar, biomass pyrolysis equipment selection is a key factor in determining production efficiency, product quality, environmental compliance, and economic benefits. Biomass charcoal production equipment suitability varies significantly across scales, feedstock types, and application scenarios, necessitating a systematic, multi-dimensional assessment. This can help avoid production losses or costly waste due to selection errors.

When choosing suitable biomass charcoal production equipment, you need to consider the following aspects, including demand positioning, core indicators, equipment type, and risk avoidance.

Demand Identification

Raw Material Form (Lumps/Pellets/Powder/Wet): If processing lumpy raw materials, such as straw and sawdust, prioritize biomass charcoal production equipment with a large feed port and anti-clogging capabilities. If processing wet materials (moisture content >50%) such as sludge and food waste, a pre-treatment drying system is required. Alternatively, consider an integrated carbonization furnace with built-in drying capabilities.

Raw Material Impurity Content: If the raw materials contain a high concentration of impurities such as metal or stone, select biomass charcoal production equipment with a feed port screening device.

Raw Material Batch Stability: If the raw material type changes frequently (e.g., alternating between rice husks, peanut shells, and tree branches), select biomass charcoal production equipment with high adjustment flexibility.

Capacity and Scale Compatibility

For small-scale trials: The mobile small biomass pyrolysis machine MJT-100 is preferred. This type of biomass charcoal production equipment has a small footprint, low investment costs, and is easy to operate.

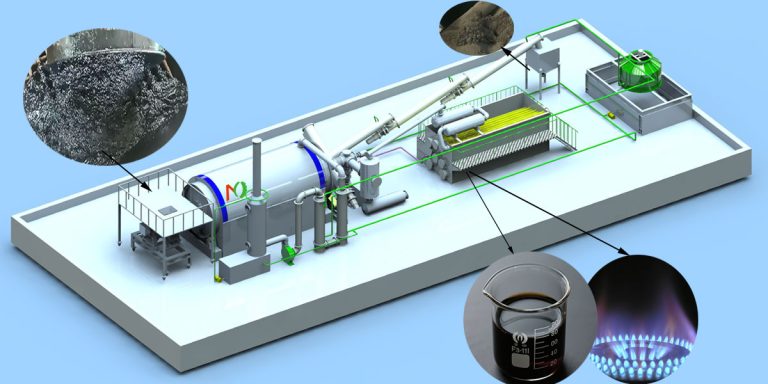

For medium-scale production: The small-capacity biochar production equipment MJT-500 and MJT-1000, MJT-2000 are recommended. Mingjie Biomass Carbonization Plant utilizes continuous pyrolysis technology, balancing production capacity with ease of operation. Furthermore, our accompanying exhaust gas treatment systems (such as cyclone dust removal and spray towers) also meet basic environmental requirements.

For large-scale industrial production: The fully continuous biomass charcoal production equipment MJT-3000 and MJT-5000, equipped with automated control systems and comprehensive exhaust gas purification and heat recovery systems, are recommended. These systems can achieve cost reductions and energy recovery at scale.

Biomass Charcoal Production Equipment Performance

The thermal efficiency of high-quality biomass carbonization equipment should be ≥70%, which can be determined by the equipment’s heat exchange structure. Mingjie biochar production equipment can recycle pyrolysis exhaust gas, reducing external fuel consumption.

Temperature control accuracy must reach ±10°C (pyrolysis temperature directly affects the fixed carbon content of biochar). Fluctuation in feed/discharge rates must be less than 5% to avoid uneven product quality due to parameter fluctuations.

When selecting biochar production equipment, consider the equipment’s automation level. Choose equipment with a PLC control system that enables real-time monitoring and automatic adjustment of temperature, pressure, and material level.

Core heating components must be made of high-temperature and corrosion-resistant materials. Q345R heat-resistant steel can be used for medium- and low-temperature carbonization. High-temperature carbonization (>800°C) requires 310S stainless steel or a silicon carbide ceramic lining.

Environmental Compliance

Biochar production equipment must be equipped with an exhaust gas treatment system that meets local environmental standards. If local requirements for particulate matter emissions are ≤10mg/m³ and VOCs ≤50mg/m³, a combined system of “cyclone dust collection + bag filter + activated carbon adsorption” should be selected. If processing sulfur-containing feedstock (such as straw), a desulfurization tower (e.g., alkali spraying) is also required.

Solid waste generated by biochar production equipment must be easily collected. Accumulation of combustible gases generated during the pyrolysis process must be avoided. The pyrolysis equipment housing must be insulated.

When choosing the right biomass charcoal production equipment, consider the raw material availability and pre-processing equipment such as crushing, pulverizing, and drying. The investment and space required for these processes should also be factored in.

A good pyrolysis plant supplier will not only provide the equipment but also offer a comprehensive solution encompassing environmental protection, energy efficiency, and product application considerations.

Biochar has a wide range of applications, including agriculture, environmental remediation, animal husbandry, and industry. Due to its high stability, biochar can sequester carbon in the soil over the long term, making it a key technology for carbon removal (CDR). Certified biochar projects can generate additional revenue in the international carbon credit market.