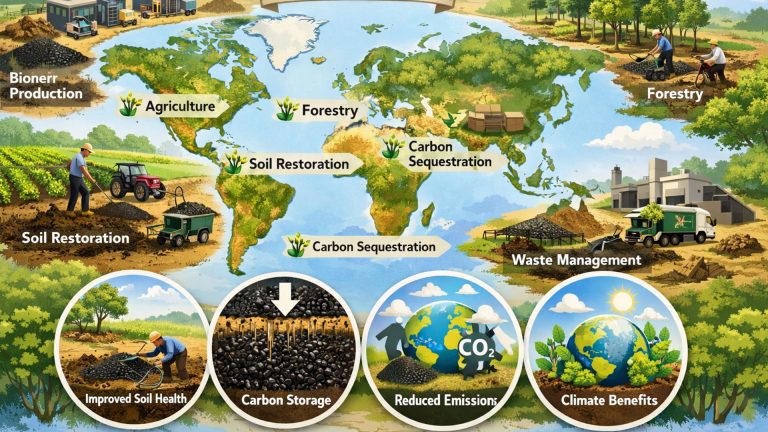

The biomass to biochar project can convert agricultural and forestry waste into biochar by biomass pyrolysis plant. Biochar, as a new type of environmentally friendly material, has the advantages of strong adsorption performance, good stability. Biochar shows great application potential in fields, such as agriculture, environmental protection and energy. The conversion of biomass to biochar is of great significance for improving the ecological environment.

Biomass to Biochar Project Investment Cost

The production costs of the Biomass to Biochar Project mainly include raw material costs, biomass production equipment costs, energy consumption, labor costs, maintenance costs and management costs.

- Raw material cost is the largest part of production cost. It mainly depends on the price fluctuation and purchase volume of agricultural waste.

- Biomass production equipment cost is a fixed cost in biomass carbonization project. These equipments have high investment cost but long service life.

- Energy consumption mainly includes heat energy consumption in carbonization process.

- Labor cost includes wages and benefits of production operators, managers and technicians.

Revenue of Biomass Carbonization Project

Sales revenue forecast is an important part of the project economic benefit analysis. According to market research and industry development trends, the sales revenue of biochar products is expected to show a trend of increasing year by year.

First, the demand for biochar as a soil conditioner in the agricultural field will continue to grow. It is expected that the sales revenue in this field will maintain an annual growth rate of more than 20% in the next five years.

Second, the demand for biochar in the environmental protection field is also expanding. Especially in water treatment and air purification, the annual growth rate is expected to reach 15%.

In the energy field, biochar is a substitute for biomass fuel, and its market demand is also gradually increasing. Considering the adjustment of the global energy structure and the promotion of environmental protection policies, the annual growth rate of biochar sales revenue in the energy field is expected to reach more than 10%.

In addition, the application fields of biochar are constantly expanding, such as as a catalyst carrier, adsorbent, etc. It is expected that the sales revenue in these emerging fields will also maintain a steady growth.

ROI of Biochar Production Equipment

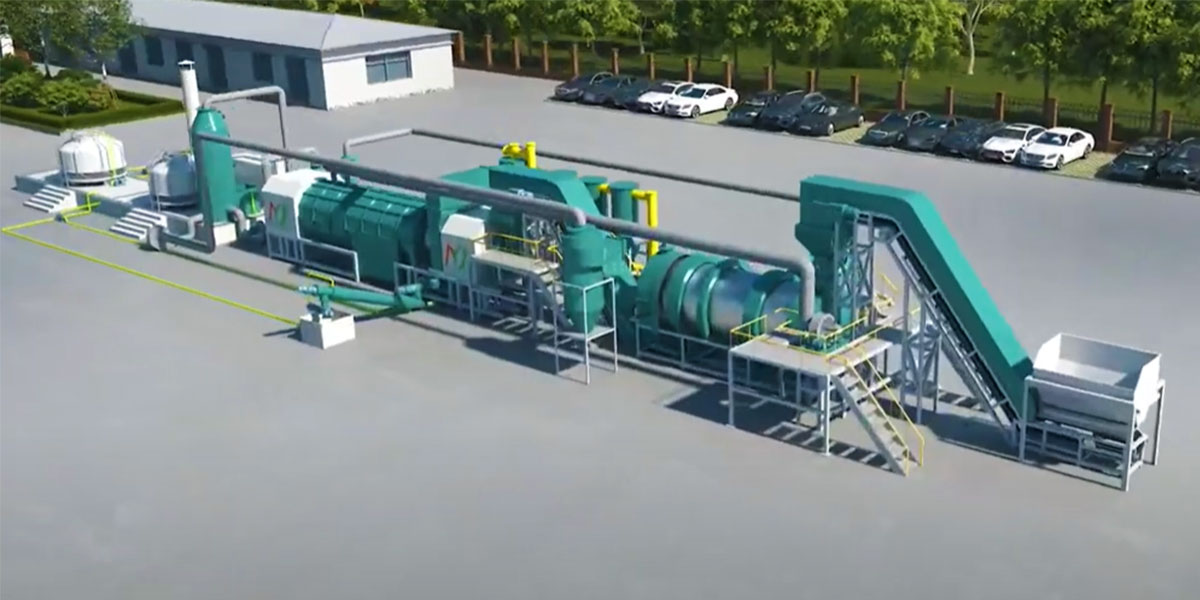

Mingjie biomass carbonization plant has a strong adaptability and flexibility. It can process various types of agricultural waste, such as rice husks, corn stalks, coconut shells, palm shells, wood, rice husks, etc. At the same time, the charcoal making machine can adjust parameters such as carbonization temperature and time according to different needs.

The profitability analysis of the biomass carbonization plant involves financial indicators, such as return on investment and net profit margin. According to forecasts, the biochar production project can achieve a return on investment of more than 20% and a net profit margin of more than 10% in the third year after it is put into operation.

This profit level will be much higher than the average level of the same industry, indicating that the project has good profit prospects. However, profitability analysis also needs to consider factors such as market risks and policy changes.

Biomass Carbonization Plant Advantages in Environmental Benefits

Biomass pyrolysis plants have significant advantages in terms of environmental benefits.

First, biomass pyrolysis machines convert agricultural waste biomass into charcoal, reducing the pollution of waste to the environment. Second, the application of biomass to biochar in agriculture, such as soil conditioner, helps to improve soil quality and reduce the use of fertilizers.

In the field of environmental protection, the adsorption properties of biochar make it an important material for treating water pollution and air pollution. By using biochar for water purification and air purification, harmful substances can be effectively removed and environmental quality can be improved. In addition, biochar also shows good results in treating heavy metal pollution, which helps to protect the ecological environment.

The biomass carbonization plant reduces energy consumption and waste emissions by recycling synthesis gas and fully enclosed production. At the same time, the biomass to biochar carbonization project will also ensure that the wastewater, waste gas and solid waste generated during the production process are properly treated by establishing a complete purification system, so as to achieve green and clean production processes.

Biomass Waste as Energy

Most biomass waste is used as the primary energy source for heating and cooking. In all countries, rural households rely more on biomass for cooking than peri-urban and urban areas. Haiti is 65%, Kenya is 72%, Democratic Republic of Congo is 78%, Nigeria is 81.5%, Tanzania is 85%, Kenya and Niger are 89%.

Wood, forestry residues, animal dung and crop waste such as straw and coconut shells are used. Although these are renewable energy sources, the stoves used to burn these fuels are inefficient. These stoves are only 10% energy efficient, so 90% of the biomass burned is wasted.

Mingjie biomass carbonization plant adopts pyrolysis technology to convert waste biomass to biochar products, such as wood charcoal, bamboo charcoal, straw charcoal, rice husk charcoal, coconut shell charcoal, etc.

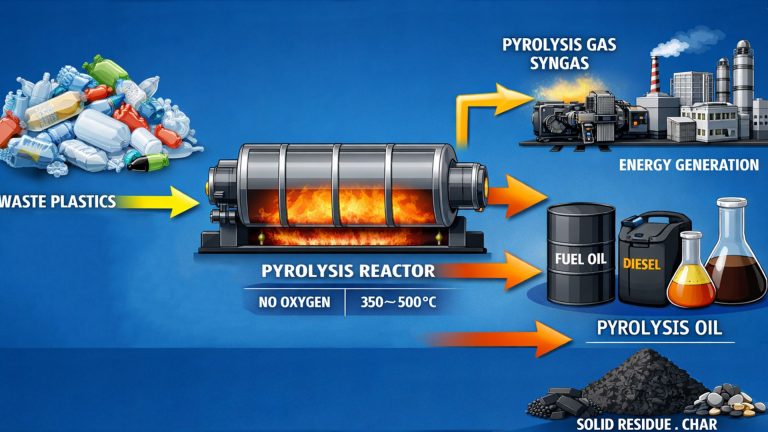

The biomass pyrolysis equipment can achieve a conversion rate of 75% to 85% for waste biomass. After pyrolysis, biomass is converted into synthesis gas, tar and charcoal products. The utilization rate of waste biomass by biomass pyrolysis equipment is mainly affected by multiple factors, such as biomass characteristics and process parameters.

Biomass to Biochar Pyrolysis Process

The biomass to biochar production process mainly includes raw material pretreatment, carbonization and purification.

The raw material pretreatment stage mainly involves crushing and drying agricultural waste.

The carbonization stage adopts high-temperature pyrolysis technology. The reactor converts the pretreated raw materials biomass to biochar in an oxygen-free or low-oxygen environment. The quality of biochar is ensured by precisely controlling parameters, such as temperature, time and pressure.

Separation and collection system can separate and collect the pyrolysis products (gas, liquid, solid) to achieve resource utilization. The fuel gas is treated by purification device, such as a bag filter and a washing tower.

The biomass pyrolysis equipment can achieve a conversion rate of 75% to 85% for waste biomass. After pyrolysis, biomass is converted into synthesis gas, tar and charcoal products. The utilization rate of waste biomass by biomass pyrolysis equipment is mainly affected by multiple factors, such as biomass characteristics and process parameters.