In the global carbon neutrality movement, carbon dioxide removal (CDR) technology is considered a key means of bridging the emissions reduction gap and achieving net-zero emissions. Biomass pyrolysis is one of the most mature and readily scalable carbon dioxide removal technologies available today. It is a key tool in the world’s journey toward net-zero emissions.

Pyrolysis removes carbon dioxide, not by directly capturing it from the air. Instead, it indirectly achieves long-term carbon sequestration and emission reduction through a closed loop of “biomass carbon sequestration – pyrolysis conversion – product sequestration/low-carbon utilization.”

Biochar is a long-term carbon storage material and an effective soil additive, improving plant yield and health. Mingjie Group is dedicated to the R&D and manufacturing of biomass pyrolysis equipment for large-scale biochar production, making a real contribution to combating climate change.

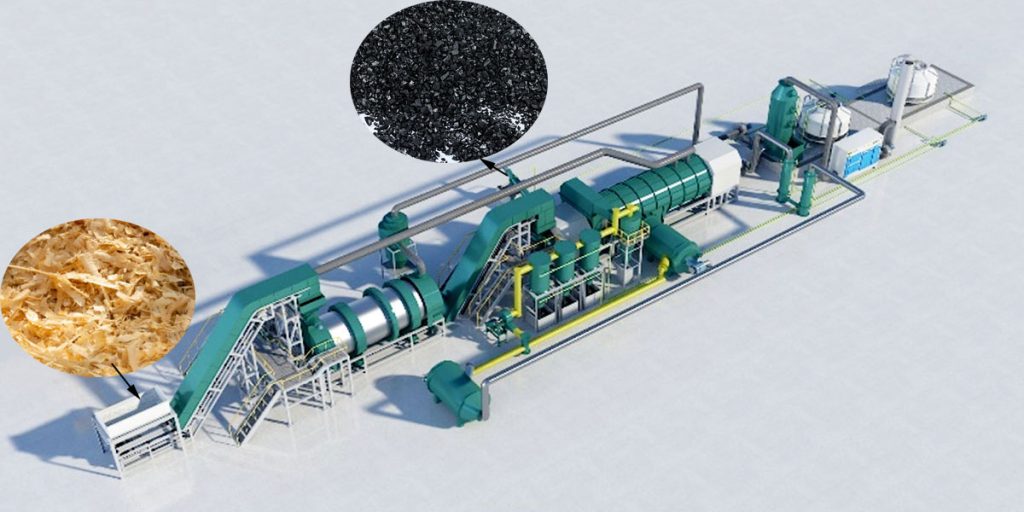

Biomass pyrolysis machine converts biomass into three main products: biochar, syngas, and pyrolysis oil.

The most critical component is biochar. As a solid product of pyrolysis, it contains 60%-80% carbon and has a stable chemical structure. Biochar can remain stable in the soil for hundreds to thousands of years, providing long-term storage of biomass-fixed carbon, preventing it from re-entering the atmosphere.

This process of “biomass carbon sequestration → pyrolysis biochar → biochar soil sequestration” essentially transfers atmospheric CO2 to soil carbon pools. This is a typical example of “Nature-Based Carbon Dioxide Removal” (NbS-CDR).

Syngas and pyrolysis oil can serve as low-carbon energy sources to replace fossil fuels, reducing the additional CO2 emissions from fossil fuel combustion.

How Biomass Pyrolysis Achieves Carbon Dioxide Removal

The effectiveness of biomass pyrolysis projects in removing carbon dioxide depends on the product’s utilization and carbon sequestration strategy. Currently, this is primarily achieved through two pathways: biochar soil sequestration and carbon-negative energy systems.

Biochar Soil Sequestration

The application of biochar to soil is the most direct carbon dioxide removal pathway from biomass pyrolysis. It directly locks in carbon, enabling long-term removal.

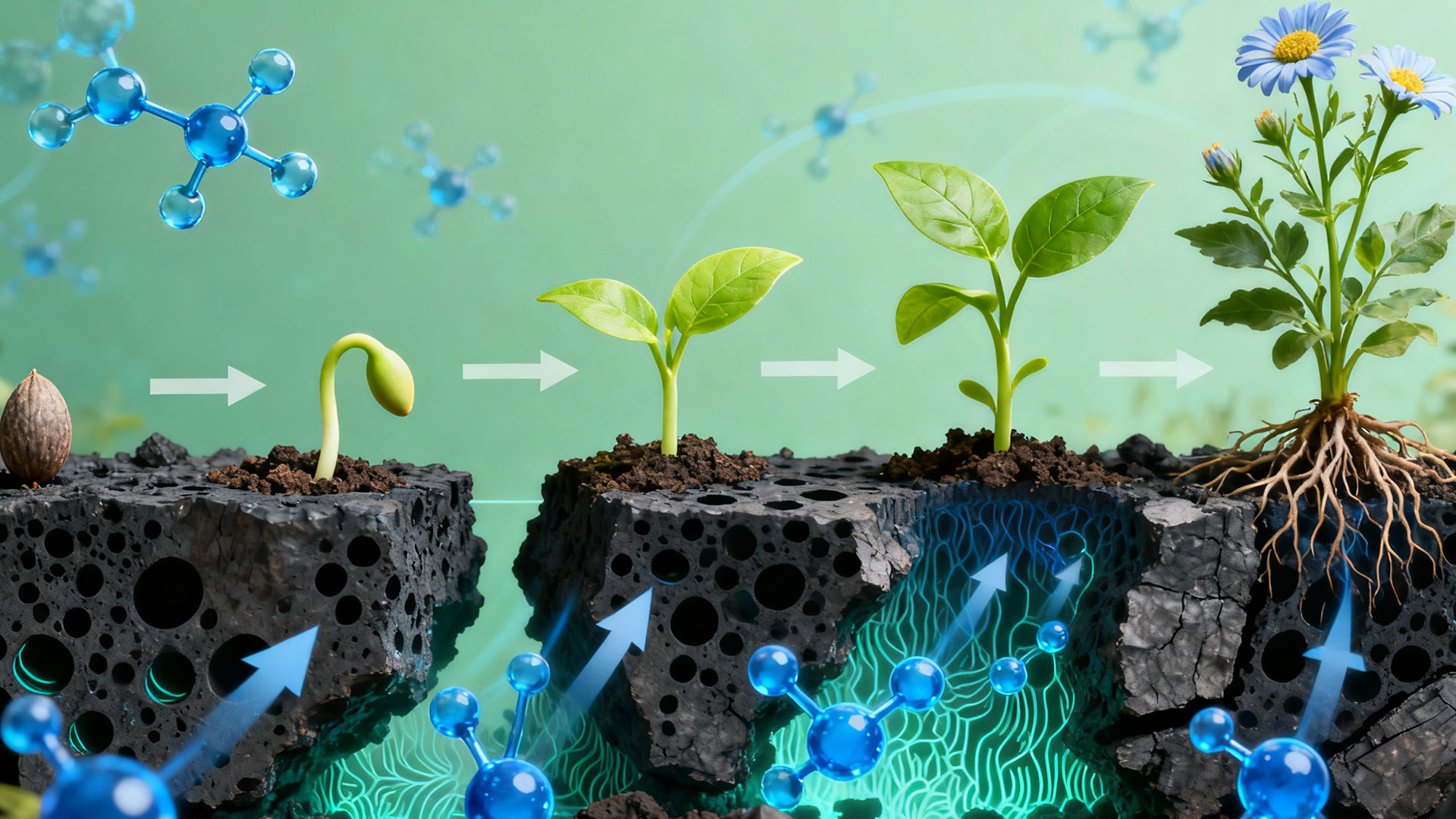

Once biochar is applied to the soil, it can sequester carbon for a long time (half-life 500-1000 years) through physical adsorption and chemical stabilization. Biochar also improves soil structure and fertility, boosting crop growth. Crops, in turn, further absorb atmospheric CO2 through photosynthesis, creating a positive cycle of “carbon removal – soil improvement – carbon sequestration.”

Carbon-Negative Energy System

Biomass pyrolysis combined with carbon capture offsets historical emissions. Combining biomass pyrolysis with carbon capture, utilization, and storage (CCUS) technology can create a “carbon-negative energy system.” When the syngas produced by biomass pyrolysis is used for power generation or heating, some carbon dioxide (from carbon absorbed by the biomass during photosynthesis) is released.

However, by capturing and storing this carbon dioxide through CCUS technology, the carbon absorbed by the biomass exceeds the carbon released, resulting in net negative carbon emissions. This effectively removes carbon dioxide from the atmosphere.

For Example,

Biomass photosynthesis absorbs CO₂ (assuming 100 tons are absorbed).

Syngas is burned to generate electricity, releasing 80 tons of CO₂ (not fully released because some of the carbon is sequestered in biochar).

CCUS captures and stores the 80 tons of CO₂ released by combustion.

The net effect: 100 tons of CO₂ reduced from the atmosphere (absorbed) – 0 tons of CO₂ (not released) = 100 tons of CO₂ removed (20 tons stored by biochar + 80 tons stored by CCUS).

Summary

Not all biomass pyrolysis projects can achieve effective carbon dioxide removal. The effectiveness of these projects is constrained by three core factors: the “carbon footprint” of the biomass raw materials, the direction of biochar utilization, and the energy consumption of project throughout its life cycle. These factors must be carefully considered in the design of biomass pyrolysis projects.

With the expansion of biochar applications (soil remediation, carbon sink trading) and the maturity of Bioenergy Carbon Capture and Storage(BECCS)technology, biomass pyrolysis is expected to become a key support for global carbon dioxide removal. It will provide an effective solution for achieving net-zero emissions.