Pyrolysis is one of the most commonly used processes in coconut shell biochar production. It involves heating coconut shell particles to a certain temperature in the absence or absence of oxygen, causing them to undergo thermochemical decomposition reactions, ultimately producing biochar, bio-oil, and syngas.

Coconut shells, after being processed in biomass pyrolysis plant, can be converted into a highly valuable material—coconut shell biochar. Coconut shell biochar has a rich pore structure, a high carbon content, and excellent adsorption properties. It shows great potential for application in soil improvement, environmental pollution control, and energy sectors.

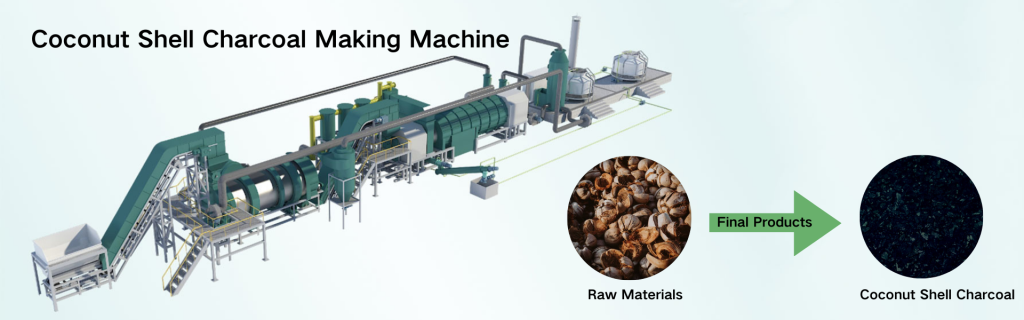

Coconut trees are widely distributed in tropical coastal and inland areas of Asia, Africa, Oceania, and the Americas. Coconut production is high, but a significant amount of coconut shells are discarded. Mingjie coconut shell biochar production utilizes pyrolysis technology to transform coconut shells into valuable resources—coconut shell charcoal. Our biomass carbonization plant enables highly efficient, continuous production of biochar.

Biochar Production Equipment Manufacturer

Mingjie Group is a professional manufacturer of biochar production equipment. We offer a variety of biomass carbonization plants, including the MJT-100, MJT-500, MJT-1000, MJT-2000, MJT-3000, and MJT-5000.

Our continuous biomass pyrolysis equipment has a minimum output of 100 kg/h and a maximum output of 5,000 kg/h. Actual biochar production efficiency depends on the moisture content of the material. Our biomass pyrolysis plants are highly adaptable and can process coconut shells, palm shells, straw, rice husks, wood chips, sawdust, and other materials.

Mingjie biochar production equipment utilizes a double-layered cylinder structure. The inner cylinder dries the material, while the outer heating zone pyrolyzes and carbonizes it. This achieves integrated drying and carbonization, ensuring the ideal biochar content.

The coconut shell biochar production machine operates 24 hours a day, smokelessly and dust-free. It separates and collects excess wood tar and pyroacetic acid, meeting environmental standards. Biochar production equipment offers higher thermal efficiency and energy savings. A multi-stage purification system effectively filters out harmful gases.

The coconut shell biochar production equipment mainly consists of drying system, pyrolysis system, product collection system, purification system, and PLC control system. The entire carbonization process is automated and easy to operate.

Coconut Shell Biochar Production Process

Crushing and Drying

The coconut shell material must first be crushed and then dried in a dryer. The feed material must have a moisture content below 15% and be smaller than 20mm in size.

Pyrolysis Carbonization

The carbonization reactor is preheated, and the material is then transferred to the reactor for pyrolysis and carbonization.

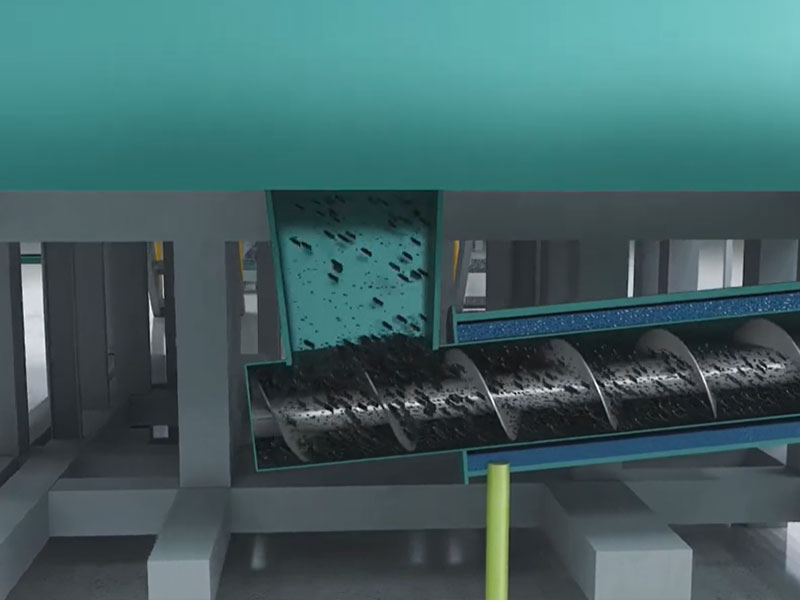

Product Collection

After 18-20 minutes of carbonization, the coconut shell can be discharged through a water-cooled discharger.

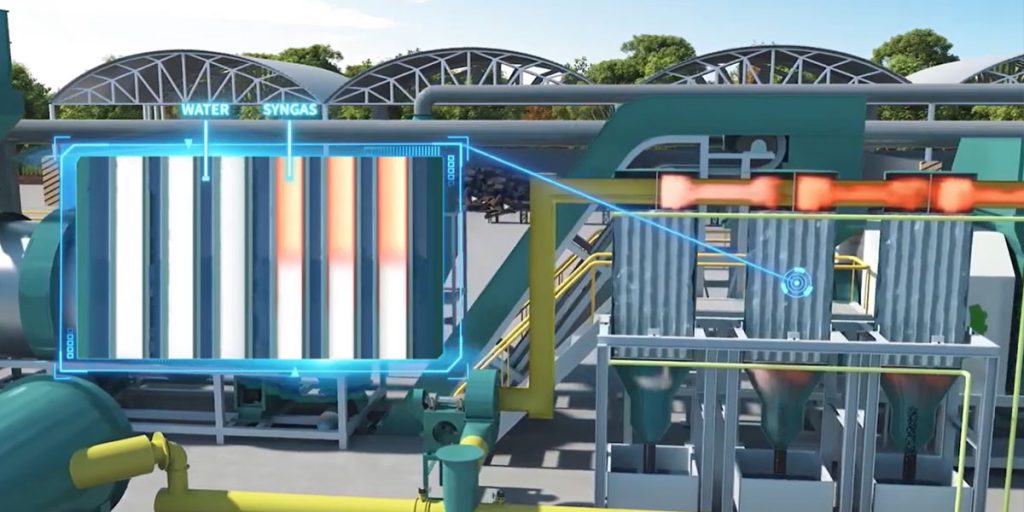

About 10 minutes after feeding, syngas is generated. It first enters a cyclone dust removal system for cleaning, desulfurization, and dust removal, then enters a condenser to separate it into wood vinegar and tar. The remaining gas is directed outside the main furnace and used to heat the reactor.

Hot Flue Gas Reuse

A portion of the waste heat is used to heat the dryer, while the remaining flue gas is discharged through a dust removal system.

Multiple Benefits of Coconut Shell Biochar Production

Coconut shell biochar has a rich porous structure, which improves soil aeration and water permeability, enhancing its ability to retain water and fertilizer. It also regulates soil pH, creating a suitable soil environment for crop growth.

Coconut shell biochar absorbs nutrients from the soil, providing a continuous supply of nutrients for crop growth. It also enhances crop disease resistance, reduces pest infestations, and improves crop yield and quality.

Coconut shell biochar production can sequester carbon over the long term, reducing atmospheric carbon dioxide levels. It acts as a carbon sequester, contributing to mitigating global climate change. Research indicates that every ton of coconut shell biochar produced can sequester approximately 0.8-1.2 tons of carbon.

Coconut shell biochar has excellent adsorption properties, effectively absorbing harmful substances, such as heavy metal ions and organic pollutants from water and soil. It can be used in sewage treatment and soil pollution control, reducing the harm of pollutants to plants and the ecological environment.