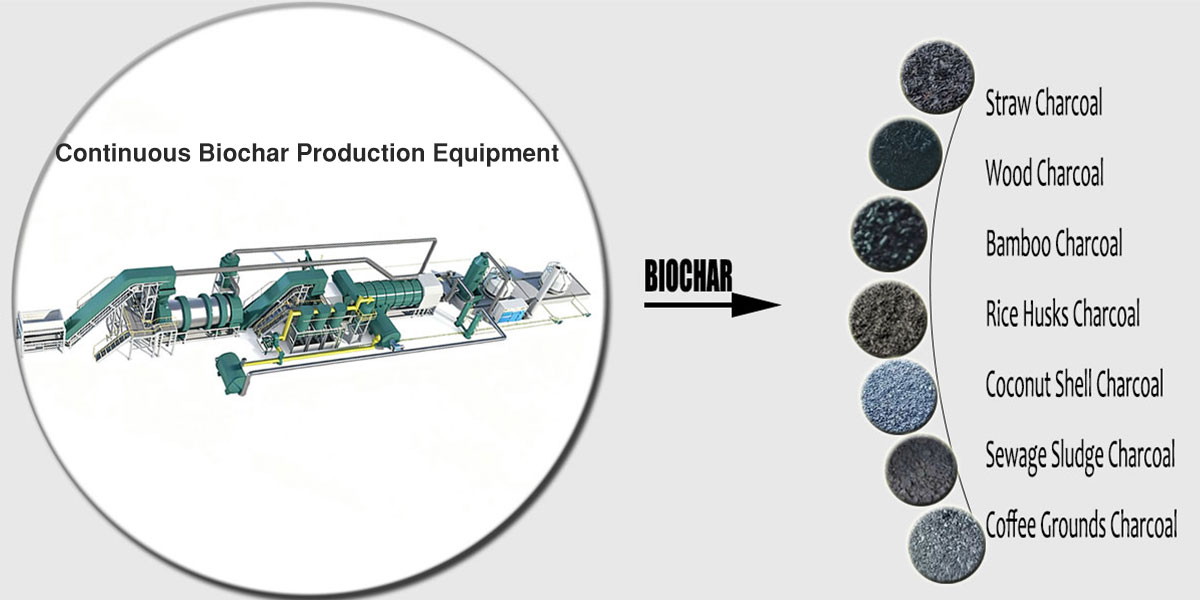

Continuous biochar production equipment converts biomass into biochar, while also operating a complete carbon reduction system. Continuous biochar production equipment is a key component in achieving carbon reduction. Its application value is reflected in the following three aspects.

Direct Emission Reduction – Biomass to Biochar Production

Biomass carbonization plant achieves carbon negativity by producing biochar. This is the core and most unique carbon reduction application of continuous biochar production equipment.

Biochar is a carbon-rich solid material produced by the high-temperature pyrolysis of biomass under oxygen-deficient or oxygen-limited conditions. Continuous biochar production equipment enables the conversion of biomass into biochar. Biochar is similar to traditional charcoal, but its core purpose differs. While charcoal is primarily used as a fuel, biochar serves as a soil conditioner and carbon sequestration medium.

Amidst the global response to climate change, carbon emission reduction has become a common goal pursued by all countries, and biochar plays a vital role in this effort. From a carbon emission reduction perspective, the core of biochar lies in its carbon sequestration.

Carbon Sequestration

Research has shown that the carbon in biochar is highly stable, remaining in environments like soil for hundreds or even thousands of years. This means that biochar removes carbon from the short-term carbon cycle and places it in a long-term storage state. This effectively reduces atmospheric levels of carbon dioxide, a major greenhouse gas.

Continuous biochar production equipment converts unstable biomass into highly stable biochar. This biochar is then sequestered in the soil, achieving long-term carbon removal.

Improved Waste Management

Biomass pyrolysis equipment effectively manages agricultural and forestry waste. This directly avoids the significant carbon emissions and air pollution caused by open-air waste burning.

Biochar can be used as an adsorbent in wastewater treatment. By absorbing pollutants, it reduces energy consumption in water treatment facilities, thereby reducing indirect carbon emissions.

Regulating Soil Ecosystems

Biochar reduces greenhouse gas emissions through its regulation of soil ecosystems. In agricultural soils, the addition of biochar can alter soil physical and chemical properties and microbial community structure. Thus, it influences the production and emission of greenhouse gases.

For example, biochar improves soil aeration and water retention, optimizes the soil environment, and alters the activity of microorganisms such as denitrifying bacteria. Denitrification is a key pathway for the production of nitrous oxide (N₂O), a potent greenhouse gas, in soil. Biochar reduces N₂O emissions by affecting the activity and abundance of denitrifying bacteria.

Biochar exhibits excellent carbon emission reduction performance and has a significant impact in the carbon trading market. Carbon trading, as an effective market-based mechanism for promoting carbon emission reduction, provides economic incentives for biochar production projects.

Energy Substitution with Biomass Pyrolysis Products

During the pyrolysis of biomass in the continuous biochar production equipment, syngas and tar are also produced. These by-products replace fossil energy.

The syngas is rich in hydrogen, carbon monoxide, and methane. Continuous biomass carbonization plant recovers this syngas and use it as an energy source. Combusting the syngas to power the pyrolysis process makes the facility energy-self-sustaining and reduces its reliance on external fossil energy sources.

Excess syngas can be used to generate electricity or provide heat to nearby facilities, directly replacing coal-fired power or natural gas.

Applications of Continuous Biochar Production Equipment

Farms/Agricultural Parks: Biomass pyrolysis equipment processes straw and livestock manure. The resulting biochar is applied to the soil, achieving on-farm carbon recycling and reducing emissions.

Wastewater Treatment Plants: Sludge carbonization equipment converts sewage sludge into biochar. This ensures harmless and resourceful disposal of the sludge, while also sequestering carbon and preventing methane emissions.

Orchards/Forestry Areas: Biochar production equipment processes forestry waste such as prunings, reducing fire hazards and producing soil conditioners.

Food Processing Plants: Continuous biochar production equipment processes processing residues (fruit shell, bagasse and rice husks), achieving waste-to-energy and carbon sequestration.