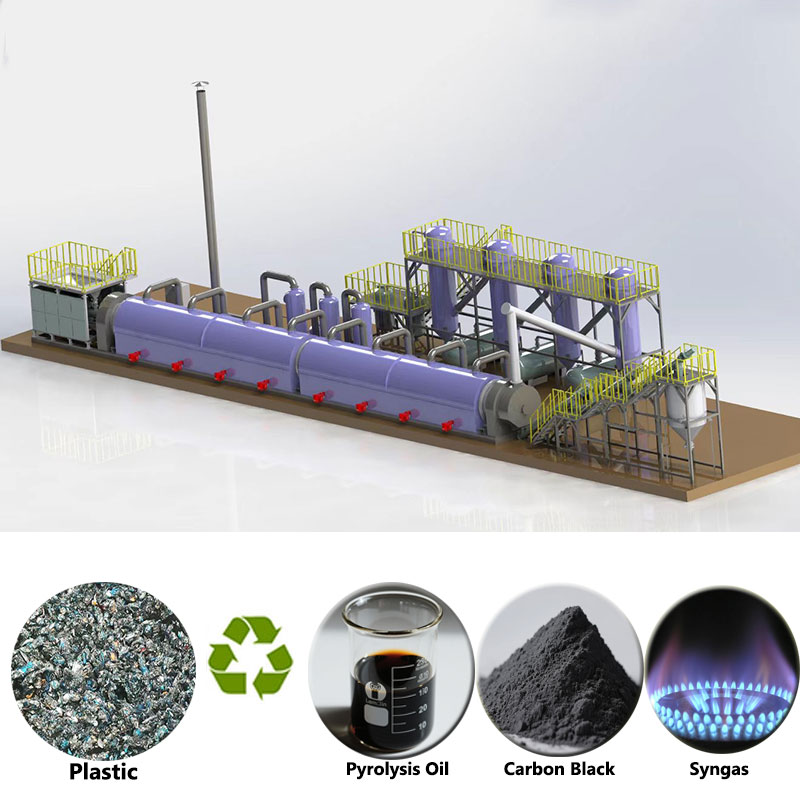

Continuous pyrolysis plants are gradually becoming popular equipment in the field of waste treatment and resource recovery around the world. Pyrolysis technology can convert various organic wastes into valuable energy under high temperature, oxygen-free or oxygen-deficient conditions. It also has a wide range of material adaptability, sufficient resource utilization capacity and potential for energy conservation and carbon reduction.

Mingjie continuous pyrolysis plant can process various solid wastes, including tires, plastics, sludge, municipal solid waste MSW, medical waste, biomass, etc. It can achieve the reduction, harmlessness and resource treatment of solid waste. Thereby providing strong support for solving environmental pollution problems and achieving sustainable development.

Our continuous pyrolysis equipment can be customized according to customer requirements. Because the main pyrolysis product of biomass is biochar, and the main pyrolysis product of plastic/tire/MSW is mainly pyrolysis oil. Therefore, the design of plastic/tire pyrolysis equipment is different from that of biomass pyrolysis equipment.

Mingjie biomass pyrolysis plant adopts continuous pyrolysis technology. Tire and plastic pyrolysis plants have three pyrolysis methods: batch, semi-continuous and fully continuous, depending on the different feeding and discharging methods.

What is the Continuous Pyrolysis Plant

The continuous pyrolysis plant is a comprehensive and systematic technical upgrade of batch pyrolysis plant. When processing a large amount of materials, the fully continuous pyrolysis plant adopts intelligent equipment to achieve continuous feeding, continuous cracking, and continuous discharging, and long-term efficient and stable operation.

In terms of safety and environmental protection, operation efficiency, energy consumption and economy, product quality stability, and intelligence, the continuous pyrolysis plant has significant advantages. It achieves the maximum recycling, realizes the resource utilization of organic solid waste, the regeneration of chemical raw materials, and carbon reduction.

Continuous Pyrolysis Reactor

As the core component, the continuous pyrolysis reactor is the space where the pyrolysis reaction occurs. It is usually made of high-quality stainless steel or special alloy materials, and has excellent high temperature resistance and corrosion resistance. They can withstand the high temperature and corrosion caused by chemical reactions during the pyrolysis process, ensuring that the reaction is carried out in a safe and stable environment.

The heating system is a key part of providing heat for the pyrolysis reaction. Common heating methods include electric heating, gas heating, fuel heating, etc. The heating system is equipped with a high-precision temperature control system. According to different pyrolysis materials and process requirements, the reaction temperature can be accurately adjusted and controlled to ensure the efficient progress of the pyrolysis reaction.

The feeding system is responsible for continuously and stably conveying the organic materials to be treated into the reactor. It usually includes a feeding hopper, a conveying pipeline and a metering device. The metering device can accurately control the feed amount to ensure the stability and consistency of the reaction process.

The discharge system is used to discharge the pyrolysis products from the reactor in time, which is divided into a gas discharge port, a liquid discharge port and a solid discharge port. The gas discharge port is connected to the subsequent gas purification and collection device. The liquid outlet conveys the liquid product to a storage tank or further processing equipment through a pipeline. The solid outlet uses a screw conveyor to discharge the solid residue for subsequent treatment or recycling.

Advantages of Solid Waste Continuous Pyrolysis

Efficient Production

Compared with batch pyrolysis plants, the biggest advantage of continuous pyrolysis plants is that they can achieve continuous operation.

After each reaction, the batch pyrolysis reactor needs to perform a series of tedious operations such as unloading and re-feeding. This not only consumes a lot of time and manpower, but also leads to interruptions in the production process, seriously affecting production efficiency.

However, the continuous pyrolysis reactor is different. The material can enter the reactor continuously, and the reaction products are continuously discharged. The entire tyre pyrolysis process does not need to be stopped, which greatly improves production efficiency.

Environmental Protection and Energy Saving

The continuous pyrolysis reactor is usually equipped with an advanced flue gas treatment system, which can purify the tail gas generated by pyrolysis to ensure that the emission meets the standards.

In terms of energy saving, the continuous pyrolysis reactor recycles the high-temperature flue gas and waste heat of the product generated during the pyrolysis process through the waste heat recovery system. These waste heat can be used to preheat feed, heat pyrolysis reactors, etc., thus greatly reducing energy consumption.

Stable Product Quality

In the continuous pyrolysis reactor, parameters (reaction temperature, pressure, and material residence time) can be precisely controlled by the automatic control system, so that the reaction process is always in a stable state.

Stable reaction conditions allow the materials to fully react in the reactor, reducing the occurrence of side reactions, thereby ensuring the quality and purity of the products. Compared with batch pyrolysis plants, the quality of products produced by continuous pyrolysis reactors is more stable. The differences between batches are smaller, which can meet the strict requirements of different industries for product quality.

In the process of producing biochar by biomass pyrolysis, the biochar produced by the continuous pyrolysis reactor has a more uniform pore size distribution and a higher fixed carbon content. Its quality is more stable, and its application effect in soil improvement, adsorbents and other fields is better.