In January 2022, Mingjie Group completed the installation of continuous pyrolysis machine for sale in China. We received feedback pictures about the on-site operation of municipal solid waste pyrolysis projects. The entire waste pyrolysis process adopts a fully enclosed production, which has the advantages of high efficiency and environmental protection.

This pyrolysis equipment adopts a fully continuous working mode, it is equipped with an automatic feeding and water-cooled automatic slag discharging system. Compared with batch pyrolysis plant, continuous pyrolysis plant can achieve high-temperature slag discharge without waiting for the cooling time of the process.

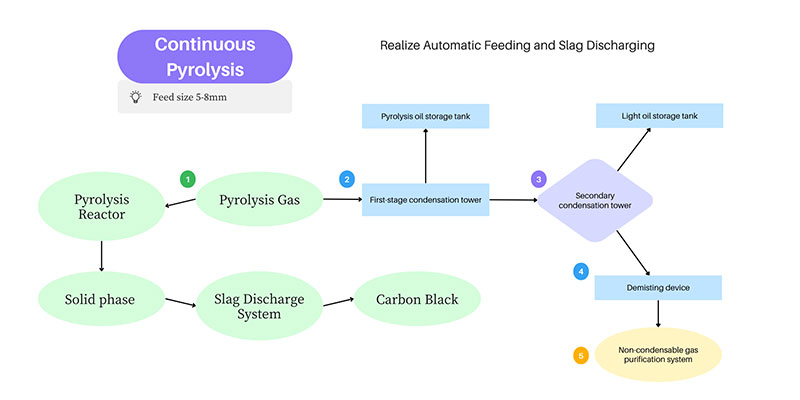

Working Process of Continuous Pyrolysis Machine

The continuous pyrolysis machine adopts the full process design of “continuous feeding – segmented pyrolysis – efficient separation – energy closed loop”. Ultimately, it realizes the large-scale energy conversion of solid waste.

Continuous pyrolysis machine achieves efficient and stable pyrolysis waste-to-energy conversion through the coordinated operation of the feeding system, pyrolysis reaction, product separation, energy circulation and other links.

Pyrolysis Gas-Liquid-Solid Separation

Continuous pyrolysis equipment is an industrial device for continuous pyrolysis of solid waste (such as PE, PP, PS and other thermoplastics). Its core goal is to convert plastics into resource products such as pyrolysis oil, carbon black, gas.

The gas phase (non-condensable gas) is removed from impurities such as HCl and tar by a scrubber (NaOH solution). Sulfides are then removed by activated carbon adsorption. Part of the clean gas is passed into the pyrolysis furnace burner for heating, and the remaining part can be used for power generation.

The liquid phase (pyrolysis oil) is condensed in two stages to collect heavy oil (diesel fraction) and light oil (gasoline fraction). The carbon powder and mechanical impurities are removed by filtration system, which can obtain pure pyrolysis oil. The pyrolysis oil can be used as fuel oil or chemical raw material.

After the solid phase (carbon black) is discharged from the tail of the furnace, it is quickly cooled to <50°C by a water-cooled screw conveyor to prevent oxidation. After screening, carbon black is obtained, which can be used to make building materials (asphalt modifier) or further purified (carbon black raw material).