The pyrolysis of tyres process requires multiple systems to work together. Each system plays an indispensable role in the continuous pyrolysis process of waste tires. The main equipment in continuous pyrolysis of tyres process includes feeding system, pyrolysis reactor, heating system, condensation system, slag discharge system and flue gas purification system.

Feeding System

The feeding system is the entrance of the tyre pyrolysis plant, including crushers and conveyors. The crusher cuts and crushes the tires into particles, preparing for the subsequent pyrolysis of tyres process. The conveyor is responsible for smoothly transporting the crushed waste tire rubber to the pyrolysis reactor.

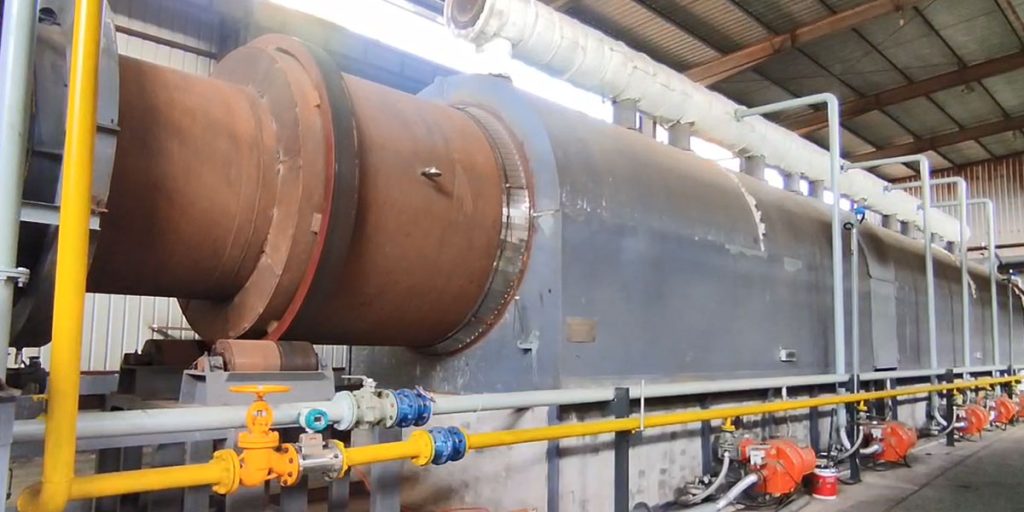

Pyrolysis Reactor

The pyrolysis reactor is the core of the tire pyrolysis plant, like the “heart” of the pyrolysis of tyres process. In a specific environment with or without oxygen, the pyrolysis reactor heats the waste tires at high temperature. During the rubber pyrolysis process, organic polymer compounds undergo cracking reactions, breaking the macromolecular chains and recombining chemical bonds. Finally, the waste tires are converted into pyrolysis oil, synthesis gas, carbon black, steel wire and other products.

Heating System

The heating system provides the required high temperature environment for the pyrolysis reaction and is the “energy source” of the tire pyrolysis process. Pyrolysis system mostly adopts efficient and energy-saving heating methods, such as gas burners, electric heaters. These heating devices can accurately control the heating temperature and rate. They ensure that the pyrolysis of tyres process is carried out under suitable conditions, while improving energy utilization and reducing tire pyrolysis plant cost.

Condensation System

The condensation system plays the role of a “separator” in the pyrolysis of tyres process. It is responsible for cooling the oil and gas produced by pyrolysis and converting it into liquid fuel oil. The condenser is a key component of the condensation system, which is usually water-cooled or air-cooled.

The water-cooled condenser uses water as a cooling medium. It transfers the heat in the oil and gas to the cooling water through heat exchange, so that the oil and gas are cooled and liquefied.

The air-cooled condenser uses air as a cooling medium. It blows cold air across the surface of the condenser through a fan, taking away the heat in the oil and gas, and realizing the cooling and liquefaction of the pyrolysis oil and pyrolysis gas.

Gas Treatment System

The gas treatment system is the “environmental protection guard” of the tire pyrolysis plant. It treats the non-condensable gas produced by pyrolysis to ensure that the emission meets the standard. The system usually includes dust collectors, desulfurization devices, etc.

The dust collector is used to remove particulate matter in the gas to prevent it from polluting the environment. The desulfurization device is used to remove harmful gases such as hydrogen sulfide in the gas to reduce pollution to the atmosphere.

Solid Handling System

The solid handling system is responsible for handling the carbon black and steel wire solid residues produced after pyrolysis. It is the “key link” of resource recovery and realizes the effective recovery of solid resources in waste tires.

Carbon black can be further processed into industrial products, such as reinforcing agents and fillers for rubber products, and colorants for inks and coatings. Steel wire can be recycled and reused, and used in steelmaking to manufacture various steel and metal products.

As an efficient and environmentally friendly waste tire treatment equipment, tyre pyrolysis plant shows broad application prospects.

As people pay more and more attention to environmental protection and resource recycling, the market recognition and acceptance of pyrolysis products will gradually increase. Pyrolysis oil, pyrolysis gas and pyrolysis carbon black will be more widely used in energy, chemical, materials and other fields.