Municipal solid waste (MSW) incineration is a highly effective method for waste reduction and harmlessness, and is widely used worldwide. However, the fly ash produced during the incineration process is classified as hazardous waste due to its presence of dioxins and heavy metals. Low-temperature pyrolysis technology provides a harmless and resource-based path for the fly ash treatment from MSW incineration.

Pyrolysis technology offers significant advantages in efficiently removing toxic and hazardous substances from fly ash and promoting resource utilization. It is expected to provide a sustainable solution for fly ash treatment.

Principles of Low Temperature Pyrolysis Fly Ash Treatment

The core principle of pyrolysis fly ash treatment is to achieve the dual goals of dioxin degradation and heavy metal separation. At the same time, it avoids the high energy consumption and secondary pollution risks of high-temperature melting.

Low-temperature pyrolysis treats fly ash under inert atmosphere. When heated to as low as 350°C for 30 minutes, dioxin degradation rates can exceed 99%.

Heavy metals in fly ash undergo a phase transformation during the low-temperature pyrolysis process. Some highly volatile heavy metals, such as Hg and Cd, transform from solid to gaseous at pyrolysis temperatures and evaporate. These volatilize and can be collected and treated using subsequent exhaust gas treatment systems.

However, relatively stable heavy metals, such as Cr and Ni, may undergo a chemical transformation, shifting from easily leached forms to less leached forms. This transformation process helps reduce the risk of heavy metal contamination during the subsequent disposal of fly ash.

Low-Temperature Pyrolysis System Design

Composition Analysis and Pretreatment: Before designing a low temperature pyrolysis process, a comprehensive compositional analysis of the fly ash must be conducted. This should include information on dioxin content, heavy metal types and concentrations, and soluble salt content.

Due to the high soluble chloride content in fly ash, pretreatment such as water washing is often required. This reduces the risk of chlorine corrosion on the pyrolysis equipment during the pyrolysis process and mitigates the potential for dioxin regeneration.

Optimizing Pyrolysis Temperature and Time: The pyrolysis temperature and time are precisely optimized based on the fly ash’s characteristics and treatment objectives. Fly ash composition varies from region to region, resulting in different optimal pyrolysis temperatures and times.

Generally, the low temperature pyrolysis temperature ranges from 300 to 500°C. However, for fly ash with specific compositions, experimental determination of the optimal pyrolysis temperature may be necessary to ensure efficient dioxin degradation and heavy metal stabilization. Furthermore, properly controlling the pyrolysis time ensures sufficient reaction time while avoiding excessive pyrolysis.

Atmosphere Control: To achieve low-temperature degradation of dioxins in fly ash and inhibit dioxin resynthesis, atmosphere control during the pyrolysis process is crucial. Inert gases (such as nitrogen) are typically used as shielding gases to create an oxygen-free or low-oxygen environment.

Precisely controlling the inert gas flow rate and introduction pattern ensures a stable inert atmosphere within the pyrolysis reactor. This prevents fly ash from coming into contact with oxygen during the pyrolysis process, which could trigger dioxin resynthesis. Furthermore, the presence of the inert gas facilitates the timely removal of volatile substances produced during pyrolysis, improving pyrolysis efficiency.

Pollutant Emission Control: During the system design process, national and local environmental standards must be strictly adhered to. Ensure that waste gas, wastewater, and waste residue generated during fly ash treatment meet emission standards.

Safety Measures: Fly ash is a hazardous waste, and the low-temperature pyrolysis process involves high temperatures and high pressures. Therefore, safety measures must be fully considered in system design.

Key Points for Pyrolysis Equipment Selection

Pyrolysis Reactor

As the core equipment in a low-temperature pyrolysis system, the pyrolysis reactor directly impacts fly ash treatment effectiveness and system operating costs. Common pyrolysis reactor types include rotary kiln, fixed-bed, and fluidized-bed types.

Rotary kiln pyrolysis furnaces offer the advantages of large processing capacity and strong adaptability. They can continuously and stably process fly ash, and the residence time of fly ash in the kiln is easily controlled.

Fixed-bed pyrolysis furnaces have a simple structure and are easy to operate, making them suitable for small-scale fly ash treatment projects. However, their processing capacity is relatively small.

Fluidized-bed pyrolysis furnaces offer high heat and mass transfer efficiency and rapid pyrolysis rates, but they place high demands on equipment sealing and gas distribution systems.

When selecting a pyrolysis reactor, various factors should be considered, including the scale of fly ash treatment, composition, and operating costs.

Exhaust Gas Treatment Equipment

The low-temperature pyrolysis process produces exhaust gas containing dioxins, heavy metal vapors, and other pollutants, necessitating efficient exhaust gas treatment equipment.

Exhaust gas treatment typically utilizes a multi-stage purification process. First, exhaust gas is removed through equipment such as cyclones and bag filters. Then, activated carbon adsorption is used to absorb dioxins and some heavy metals. Exhaust gas containing acidic gases (such as HCl) is neutralized using methods such as alkaline solution spraying.

In addition, to achieve standard emissions, catalytic combustion and selective catalytic reduction (SCR) technologies may be required to further remove harmful substances from the exhaust gas.

Supporting Equipment

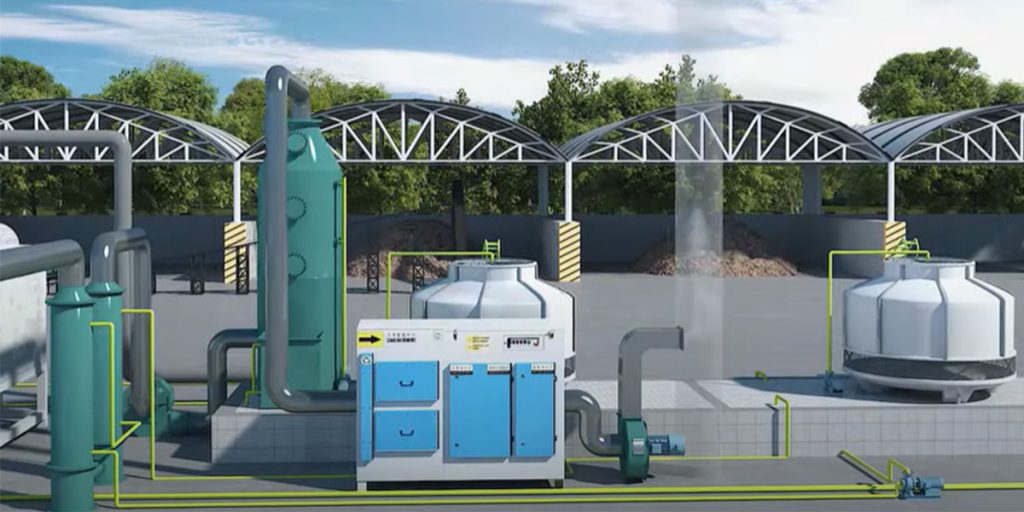

In addition to the pyrolysis furnace and tail gas treatment equipment, the low-temperature pyrolysis system also includes supporting equipment such as a feeder, discharger, heating system, and cooling system.

The feeder should accurately meter and stably deliver fly ash, ensuring a uniform and continuous flow of fly ash into the pyrolysis furnace.

The discharger must ensure smooth discharge of pyrolyzed fly ash and prevent air from entering the pyrolysis furnace and affecting atmosphere control.

The heating system can utilize electric, gas, or other heating methods to meet the temperature requirements of the pyrolysis process.

The cooling system cools the fly ash and tail gas after pyrolysis for subsequent processing.

To enhance system stability and reliability, an automated control system should be implemented. This system can monitor and adjust key parameters such as pyrolysis temperature, gas flow rate, and pressure in real time.

Summary

Low-temperature pyrolysis technology offers significant advantages in degrading dioxins, stabilizing heavy metals, and achieving resource utilization in fly ash. It provides a sustainable solution for treating municipal solid waste incineration fly ash. Through rational system design and equipment selection, combined with practical application, low-temperature pyrolysis technology can effectively and efficiently render fly ash harmless and recycle it.