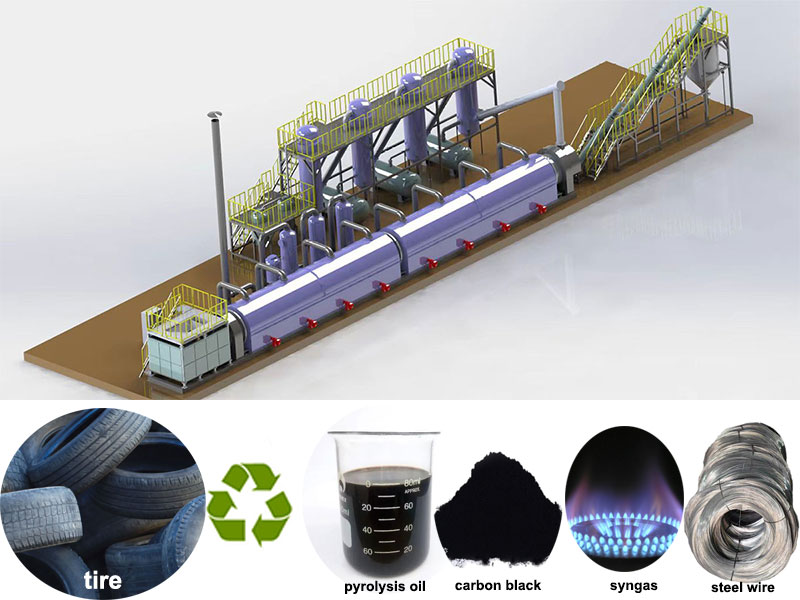

Unlike the batch pyrolysis plant, the fully continuous pyrolysis plant realizes waste tire recycling by continuous feeding, pyrolysis reaction and output. The fully continuous pyrolysis plant has the advantages of large processing capacity, low energy consumption and high degree of automation. It is particularly suitable for large-scale disposal of waste tires.

Core Process of Fully Continuous Waste Tire Recycling Pyrolysis

The flow chart of the fully continuous waste tire recycling process can be divided into four core modules: pretreatment, pyrolysis reaction, product separation and purification, and resource recovery.

Pretreatment stage

Remove the steel wire from the waste tires and crush them into 5-8mm particles.

The crushed tires may contain some metal impurities, which need to be treated by magnetic separation.

Waste Tire Pyrolysis Process

The pre-treated waste tire blocks are continuously fed into the pyrolysis reactor through an automatic feeding device. The pyrolysis reactor is equipped with a heating device. When the material enters the reactor, as the cylinder slowly rotates, the material rolls and moves forward in the cylinder, so that it can be evenly heated.

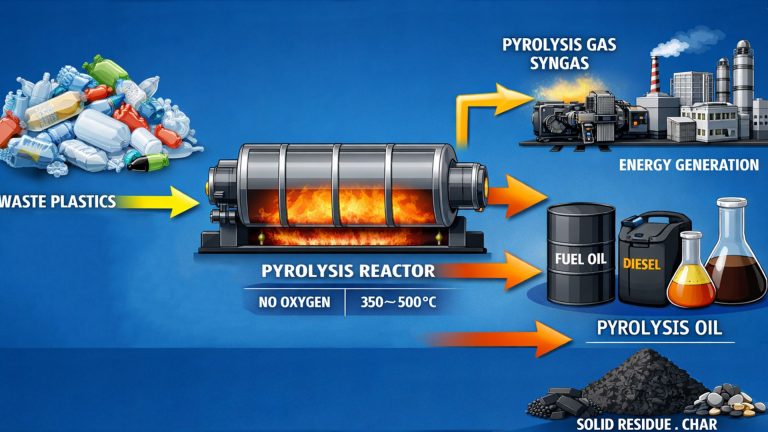

In the pyrolysis reactor, temperature is the key factor in the continuous pyrolysis process, and the temperature is usually controlled within the range of 300-700°C. In this temperature range, the rubber molecules in the waste tires begin to undergo violent thermal decomposition reactions.

During the pyrolysis reaction, a micro-negative pressure environment needs to be created. By extracting the air in the pyrolysis reactor, the pressure in reactor is slightly lower than the external atmospheric pressure. The role of the micro-negative pressure environment mainly has two aspects:

- First, it prevents the outside air from entering the reactor, preventing oxygen from oxidizing with the pyrolysis products, and affecting the quality and yield of the products.

- Second, it is conducive to the timely discharge of the oil and gas produced by pyrolysis from the reactor to improve the reaction efficiency.

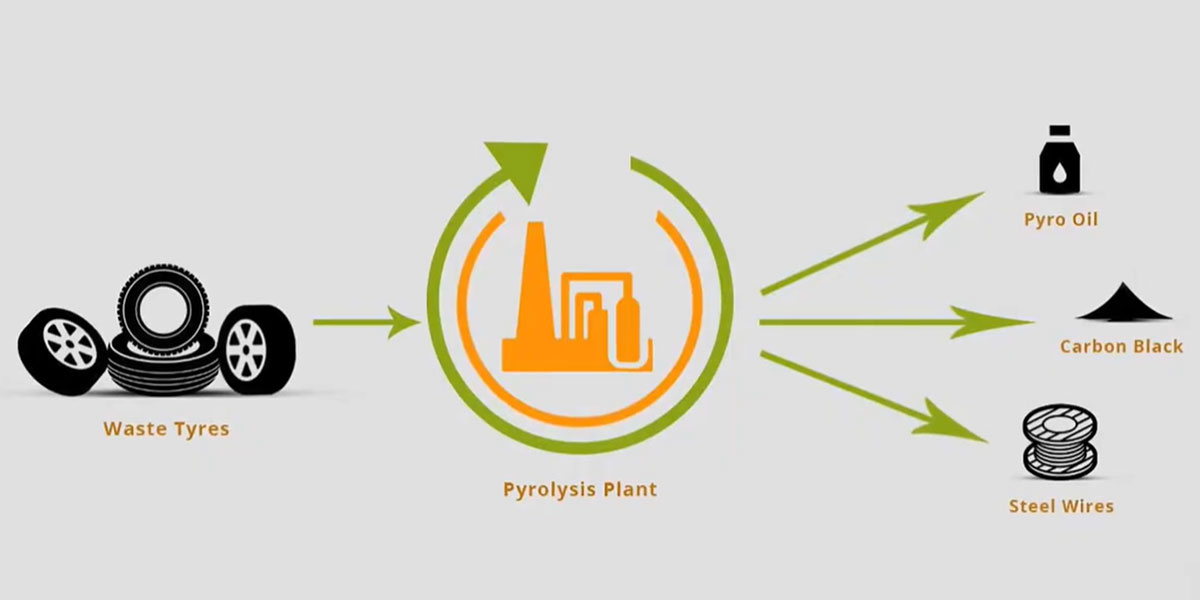

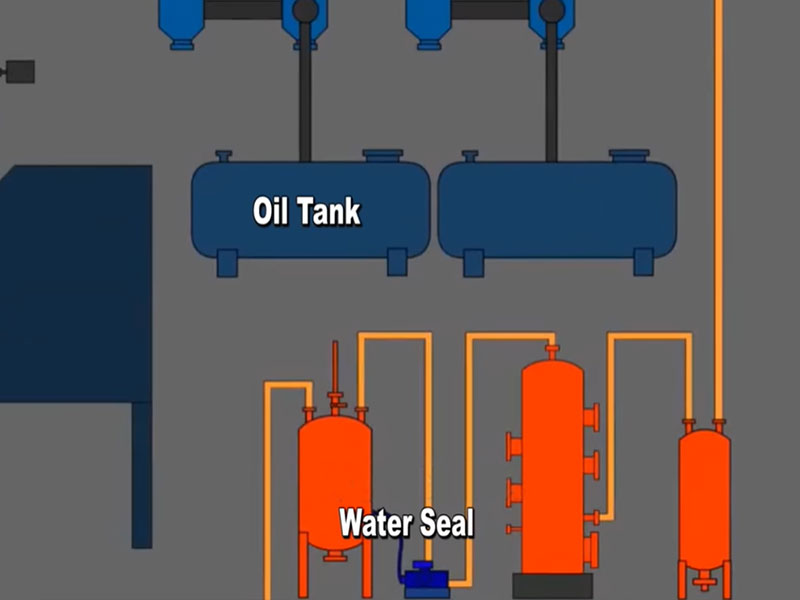

Under the combined action of anaerobic conditions and high temperature, tyre recycling pyrolysis plant gradually converts waste tire into pyrolysis oil and syngas, carbon black and steel wire.

Pyrolysis Products Collection

Carbon black is one of the solid products of waste tire pyrolysis reaction and has high economic value. The steel wire that is not completely separated will also remain after tire pyrolysis process, which is convenient for subsequent recycling and reuse.

Oil and gas contain a variety of organic compounds, such as alkanes, olefins, aromatics, etc. They are important raw materials for the subsequent condensation separation and preparation of fuel oil.

The oil and gas discharged from the pyrolysis reactor need to be separated by condensation to convert them into usable fuel oil. The condensation system uses circulating cooling water as the cooling medium to achieve efficient cooling and separation of oil and gas.

Oil Gas Separation

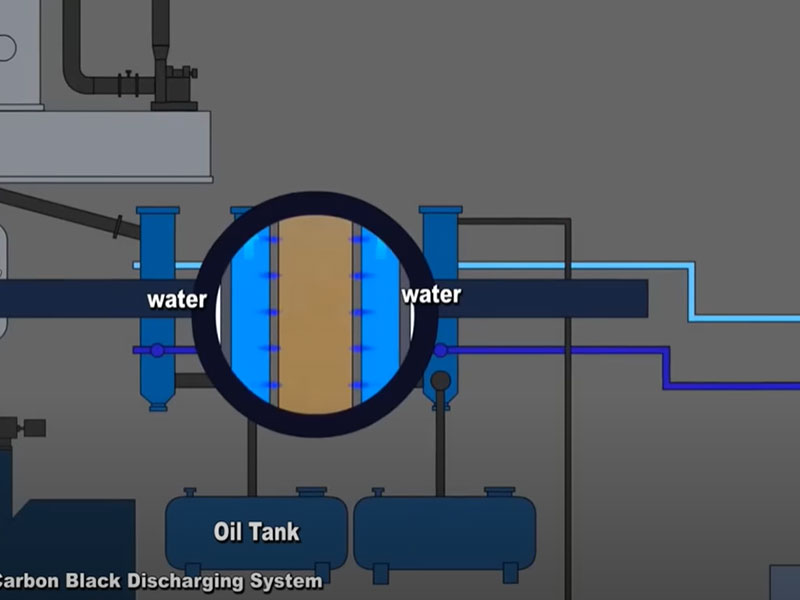

The condenser usually adopts a shell-and-tube structure, which consists of multiple parallel pipes. The oil and gas flow in the pipes, while the circulating cooling water flows outside the pipes, exchanging heat through the pipe walls.

When the high-temperature oil and gas enter the condenser, they come into contact with the low-temperature circulating cooling water. The heat in the oil and gas is quickly absorbed by the cooling water, and the temperature drops sharply. As the temperature decreases, the gaseous oil in the oil and gas gradually liquefies to form liquid fuel oil.

During the condensation process of pyrolysis plant, in order to improve the condensation efficiency, the fluid in the condenser adopts a countercurrent method. This can increase the average temperature difference and enable the oil and gas to be cooled more fully.

After the initial condensation in the condenser, most of the oil and gas are liquefied into fuel oil. However, there is still a small amount of uncondensed oil and gas and non-condensable gas. These remaining gas mixtures enter the cooling water tank for further cooling.

The cooling water tank is filled with low-temperature cooling water. The gas mixture bubbles through the water and fully contacts with the cooling water, further reducing the temperature and liquefying more gaseous oil.

After being processed by the cooling water tank, most of the oil and gas are successfully condensed into fuel oil. These fuel oils flow into the collection device through the pipeline for subsequent storage and processing.

Synthetic Gas Processing

The non-condensable gas that has not been condensed mainly includes hydrogen (H₂), methane (CH₄), carbon monoxide (CO), etc. These synthetic gases have high combustion value.

In order to make full use of resources, the non-condensable gas is recovered and transported to the combustion system through pipelines. It is used as fuel for pyrolysis reactors to provide partial energy support for the entire tire pyrolysis process. This achieves self-sufficiency in the heat energy required for continuous pyrolysis system and improves energy utilization efficiency.

Resource Recovery

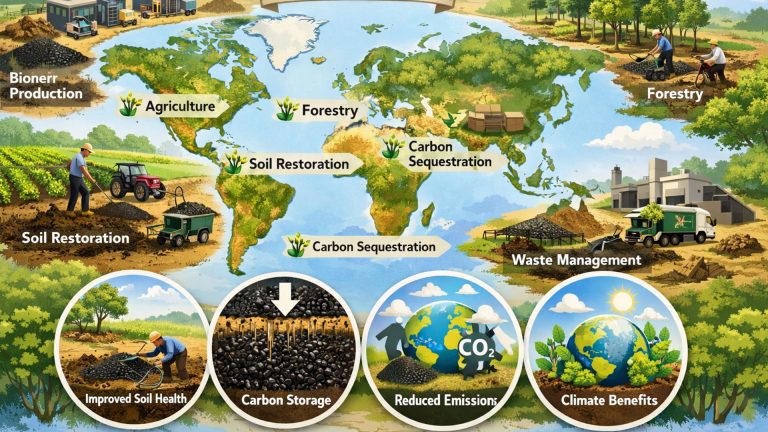

The carbon black and fuel oil obtained by waste tire pyrolysis need further processing to truly realize their value.

The original carbon black produced by waste tire pyrolysis contains a certain amount of impurities, and its direct use value is low. In order to improve the quality and added value of carbon black, it needs to be subjected to a series of deep processing.

The processing of waste tire pyrolysis oil is also crucial. The fuel oil obtained by condensation is a mixed oil containing a variety of hydrocarbon compounds with different components. In order to improve the quality and purity of fuel oil, it needs to be distilled and purified. Filtration, sedimentation, distillation and other methods are usually used.

The waste oil distillation equipment further separates and purifies the various components in the pyrolysis oil according to the difference in boiling points. Finally, the waste tire pyrolysis oil is converted into non-standard diesel and gasoline. These fuel oils can be widely used as fuel sources for industrial boilers and furnaces.