The nut shell charcoal making machine solves the challenge of nut shell waste disposal while converting it into high-value-added products. It serves as a key link between the nut processing industry and the environmentally friendly energy industry. Nut shells (such as walnut shells, almond shells, macadamia shells, and coconut shells) are excellent raw materials for producing high-quality biochar due to their high hardness and lignin content.

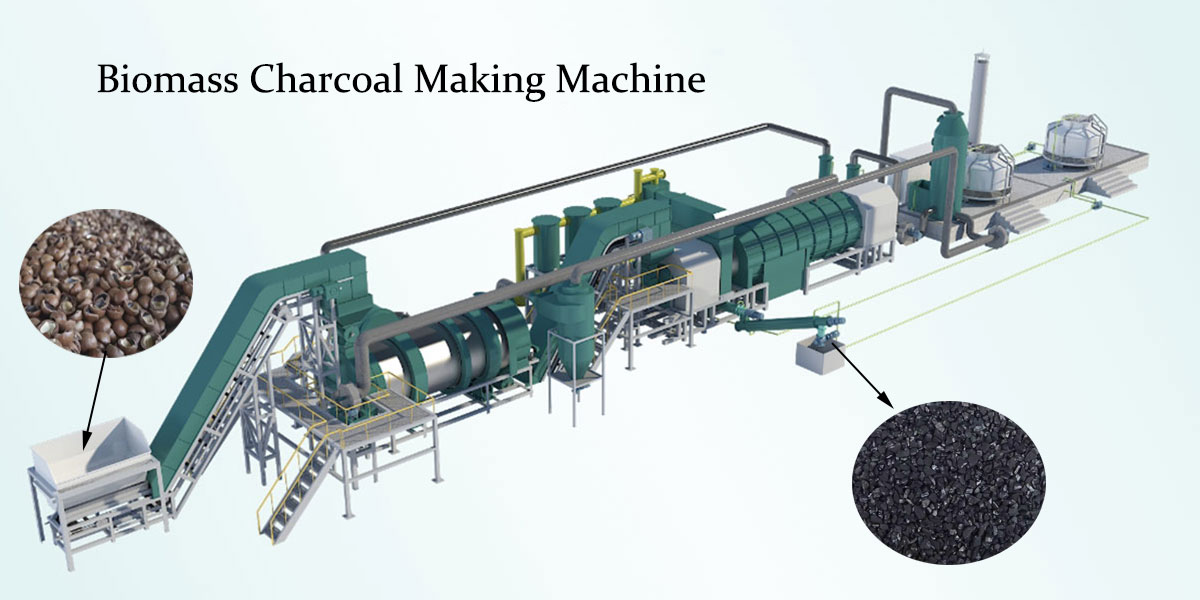

The nut shell charcoal making machine heats nut shells under oxygen-deficient or anaerobic conditions, causing them to undergo thermochemical decomposition. Ultimately, the nut shells are converted into biochar, tar, and syngas.

With the booming nut processing industry, the production of various nut shells, including peanut shells, walnut shells, chestnut shells, and macadamia shells, has increased significantly annually. According to incomplete statistics, the global output of nut shell waste exceeds 20 million tons annually. While seemingly harmless, these shells present numerous challenges in their disposal.

Traditional disposal methods primarily rely on incineration and landfilling. Incineration produces dense smoke containing large amounts of particulate matter and harmful gases, exacerbating air pollution. Landfilling consumes valuable land resources, and nut shells take up to 2-3 years to degrade. They can harbor mosquitoes and produce leachate that pollutes soil and groundwater.

At the same time, the new energy and environmental protection industries are experiencing increasing demand for high-quality carbon materials and biomass energy. Nut shells, rich in cellulose, hemicellulose, and lignin, are ideal biomass feedstocks. Driven by the “dual carbon” goals and policies for solid waste recycling, Nut Shell Charcoal Making Machine has emerged.

Advantages of Nut Shell Charcoal Making Machine

Waste Utilization, Turning Waste into Treasure

The nut shell charcoal making machine converts agricultural waste into high-value products, reduces environmental pollution. After pyrolysis carbonization, nutshells reduce their volume by over 70% and their weight by 50%-60%.

Nutshell charcoal can be used in soil improvement, water purification, electrode materials, and other fields. Combustible gas can directly power the biochar production equipment. Tar can be refined into chemical raw materials such as phenols and aromatics.

Carbon Negative Technology

The entire nut shell charcoal making process stabilizes atmospheric carbon dioxide, contributing to mitigating the greenhouse effect. The oxygen-free pyrolysis process eliminates harmful gases (dioxins and sulfur dioxide) produced by incineration. The nut shell carbonization process also kills insect eggs and pathogens that may be present in the nutshells.

High Product Value

The hardness and pore structure of nutshell charcoal are particularly suitable for producing high-grade activated carbon, offering significant economic benefits.

Achieving a Circular Economy

The payback period for nut shell charcoal making machine is only 2-3 years, providing a sustainable solution for agriculture and industry.

Peanut Shell Carbonization Equipment Application

A large peanut processing company in Henan, China, introduced a MJT-2000 peanut shell carbonization equipment in 2023 and quickly turned a profit after commissioning.

This company processes 100,000 tons of peanuts annually, generating approximately 30,000 tons of peanut shell waste. Previously, the company disposed of the peanut shells using a combination of open-air incineration and landfilling. Not only did this cost them annual landfill site rental fees, but they were also repeatedly penalized by environmental protection authorities for pollution from incineration, threatening production suspension.

The nut shell charcoal making machine operates in a fully enclosed process, and the accompanying exhaust gas purification system treats exhaust gases to below emission standards. The peanut shell charcoal production process is smoke-free and odorless, completely eliminating the risk of environmental penalties.

The peanut shell charcoal produced by the biomass carbonization plant provides a low-cost soil improvement material for local agriculture.

Mingjie biomass carbonization plant is not only used for nutshell carbon production, but also for various organic solid wastes treatment, such as sludge, animal manure, agricultural waste, forestry waste, etc.