The palm kernel shell biochar making machine converts agricultural waste palm kernel shells into high-value biochar. It plays a significant role in energy supply, environmental protection, and industrial development. The biochar production equipment utilizes pyrolysis technology to process waste biomass, opening up a new approach to waste treatment.

Palm kernel shells are the shredded shells left after the palm kernels are removed from the palm oil mill. They are fibrous, contain relatively low water content (11%-13%), low ash content (2-3%), and contain 20-22% pure carbon (fixed carbon). Charcoal made from palm kernel shells is high-quality due to its lignocellulosic content. Furthermore, it produces approximately 20.093 kilojoules/kg more heat energy than regular charcoal.

Mingjie Biomass Carbonization Plant is capable of processing a variety of waste biomass, including waste wood, straw, rice husks, wood chips, sawdust, coconut shells, bagasse, and palm shells. Our palm kernel shell biochar making machines utilize a continuous biochar production process. We offer a variety of palm kernel shell biochar making machine models, including the MJT-100, MJT-500, MJT-1000, MJT-2000, MJT-3000, and MJT-5000. Our biomass processing capacity ranges from 100 kg/h to 5000 kg/h.

How to Make Palm Kernel Shell Biochar?

The core operating principle of palm kernel shell biochar making machine is based on pyrolysis technology, a high-temperature decomposition process of organic matter in an oxygen-deficient or low-oxygen environment.

The palm kernel shells are first crushed and dried, resulting in small particles less than 20mm. Pretreatment of the palm kernel shells is crucial. The appropriate size of the kernels facilitates the subsequent carbonization stage and a more efficient pyrolysis reaction.

Once pretreatment is complete, the palm kernel shells enter the pyrolysis reactor of palm kernel shell biochar making machine. The palm kernel shell biomass pyrolysis process typically takes place between 300 and 800°C. Oxygen intake is strictly controlled within the reactor to create an oxygen-deficient environment.

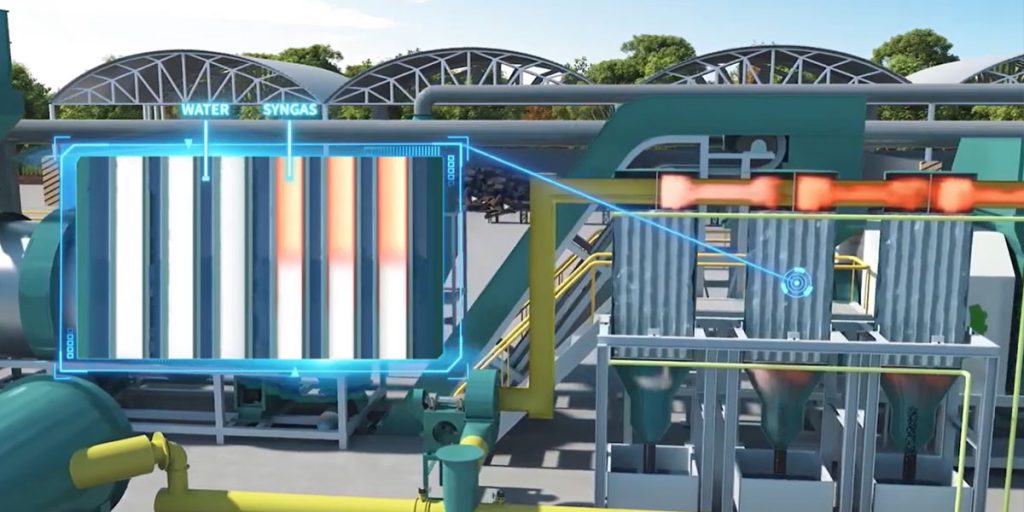

Under these high-temperature and oxygen-deficient conditions, the organic components in the palm kernel shells begin to undergo complex thermochemical reactions. Volatile substances, such as water and tar, rapidly evaporate, forming syngas. After purification and treatment, this syngas can be used as fuel to partially power the pyrolysis reactor, achieving energy recycling.

The remaining unvolatile components gradually carbonize, forming carbon-rich biochar. Biochar has a highly stable aromatic structure and abundant pores, which give it strong adsorption capacity and unique physical and chemical properties.

Palm shell charcoal has high strength and density, so the carbonization temperature should be maintained above 600°C. The higher the temperature, the shorter the carbonization time. The carbonized palm shell is discharged from the carbonizer’s outlet.

The resulting biochar is relatively hot, so to ensure stable performance, it requires a cooling system. Cooling is typically done using air or water cooling, which rapidly reduces the biochar’s temperature to room temperature through heat exchange. After cooling, the palm shell charcoal can be directly packaged and stored.

Advantages of Palm Kernel Shell Biochar Making Machine

Efficient Conversion, Excellent Productivity

The palm kernel shell biochar making machine demonstrates exceptional conversion efficiency and production capacity. Its conversion rate is 20%-30% higher than conventional equipment. Its continuous production mode meets the needs of large-scale industrial production and commercial applications. Its efficient conversion and strong production capacity significantly improve production efficiency and reduce unit production costs.

Environmental Protection, Green Model

The charcoal making machine is a true environmental leader in biochar production process. The syngas generated during the pyrolysis process is recycled and used as part of the energy for heating. This reduces reliance on external fossil fuels and lowers carbon emissions.

Compared to traditional waste incineration or landfill disposal, it avoids the emission of significant amounts of harmful gases and greenhouse gases, reducing air pollution.

The palm kernel shell biochar making machine utilizes advanced exhaust gas purification and dust treatment systems. These systems desulfurize, denitrify, and remove dust from the small amount of waste gas generated before it meets emission standards, effectively controlling secondary pollution.