Pyrolysis technology is characterized by its high efficiency, environmental friendliness, and resource recovery. It is considered one of the most promising technologies for petroleum sludge treatment and disposal.

Petroleum sludge is one of the major hazardous solid wastes generated during petroleum extraction, transportation, refining, and storage. Oil sludge can come from a wide range of sources, including oil fields, refineries, or storage tanks. Its composition is extremely complex, consisting of a stable emulsion mixture of oil, water, and solid particles. Improper handling can cause serious environmental and health risks.

Petroleum sludge pyrolysis technology is a highly attractive waste treatment and resource recovery pathway. It successfully transforms environmental burdens into economically valuable energy and materials, perfectly aligning with the concept of a circular economy.

Unlocking Resource Recovery in Petroleum Sludge Treatment

The core of petroleum sludge treatment through pyrolysis technology is to simultaneously achieve “pollutant degradation” and “resource recovery.” The oil sludge pyrolysis process typically takes place within a temperature range of 400-800℃, with oxygen content controlled throughout to prevent complete combustion of organic matter.

Under high temperatures, large organic molecules in petroleum sludge undergo cracking, chain breaking, and dehydrogenation reactions. It gradually breaks down into smaller molecules, eventually forming three types of products. The products of petroleum sludge pyrolysis are similar to those of ship waste oil sludge, but their specific properties and uses are different.

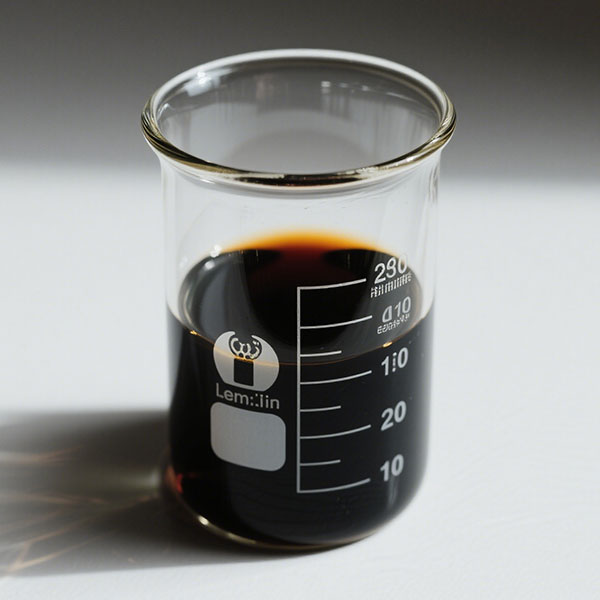

Pyrolysis oil: Primarily composed of light aromatics, alkanes, and small amounts of phenols. Its calorific value can reach 40-45 MJ/kg, close to that of traditional diesel and heavy oil. Pyrolysis oil can be used as boiler fuel and generator fuel. It can also be further distilled and refined into light fuel oil components, achieving the recycling of petroleum resources.

Solid carbon black: Its main components are carbon (60%-80%), inorganic minerals, and incompletely pyrolyzed solid residues. It may also adsorb small amounts of heavy metals. Pyrolysis carbon has a large specific surface area and, after activation treatment, can be used as an adsorbent for wastewater treatment and soil remediation. If the heavy metal content exceeds the standard, it can be solidified and stabilized before being disposed of according to hazardous waste regulations. Alternatively, it can be used as an additive in building materials for harmless utilization.

Syngas: Mainly composed of methane, ethane, propane, hydrogen, and carbon monoxide, it has a high calorific value (typically 16-25 MJ/m³). It can be used directly as fuel in the heating stage of the pyrolysis system, achieving energy self-sufficiency. Alternatively, it can be purified and used as industrial fuel.

Petroleum Sludge Pyrolysis Treantment Application

The use of pyrolysis technology for petroleum sludge treatment has yielded numerous successful cases in practical applications, providing strong practical support for its further promotion and application.

In a petroleum sludge treatment project, various traditional methods were tried, but none achieved the desired results. The situation was greatly improved after adopting pyrolysis equipment. This equipment is equipped with a dual purification system for exhaust gas and flue gas. This ensures the entire treatment process is safe, energy-efficient, and generates and transfers no secondary pollution.

During the oil sludge treatment process, the petroleum sludge first undergoes pretreatment to remove large impurities and reduce its water content. It then enters the pyrolysis reactor, where the organic matter in the sludge rapidly decomposes, transforming into gaseous, liquid, and solid products. After a period of operation, the treatment efficiency has significantly improved, and the volume and weight of the previously massive sludge have been significantly reduced.

Statistics show that the treated sludge volume has decreased by more than 80%, and its weight by about 70%. Simultaneously, the recovered pyrolysis oil and combustible gases provide additional energy support for oilfield production, achieving a win-win situation for resource recovery and environmental protection.

Unique Advantages of Petroleum Sludge Pyrolysis Treatment

- Highly Efficient Resource Recovery: It maximizes the conversion of petroleum hydrocarbons in the sludge into fuel oil, fuel gas, and charcoal residue, turning waste into treasure.

- Complete Detoxification: High temperatures effectively decompose pathogens and organic pollutants. Heavy metals are immobilized in stable charcoal residue, significantly reducing leaching toxicity. The anaerobic environment fundamentally prevents dioxin formation.

- Significant Volume Reduction: Volume reduction is typically >90%, greatly reducing the final disposal volume.

- Wide Treatment Range: It can treat petroleum sludge from various sources with different moisture and oil contents, demonstrating strong adaptability.