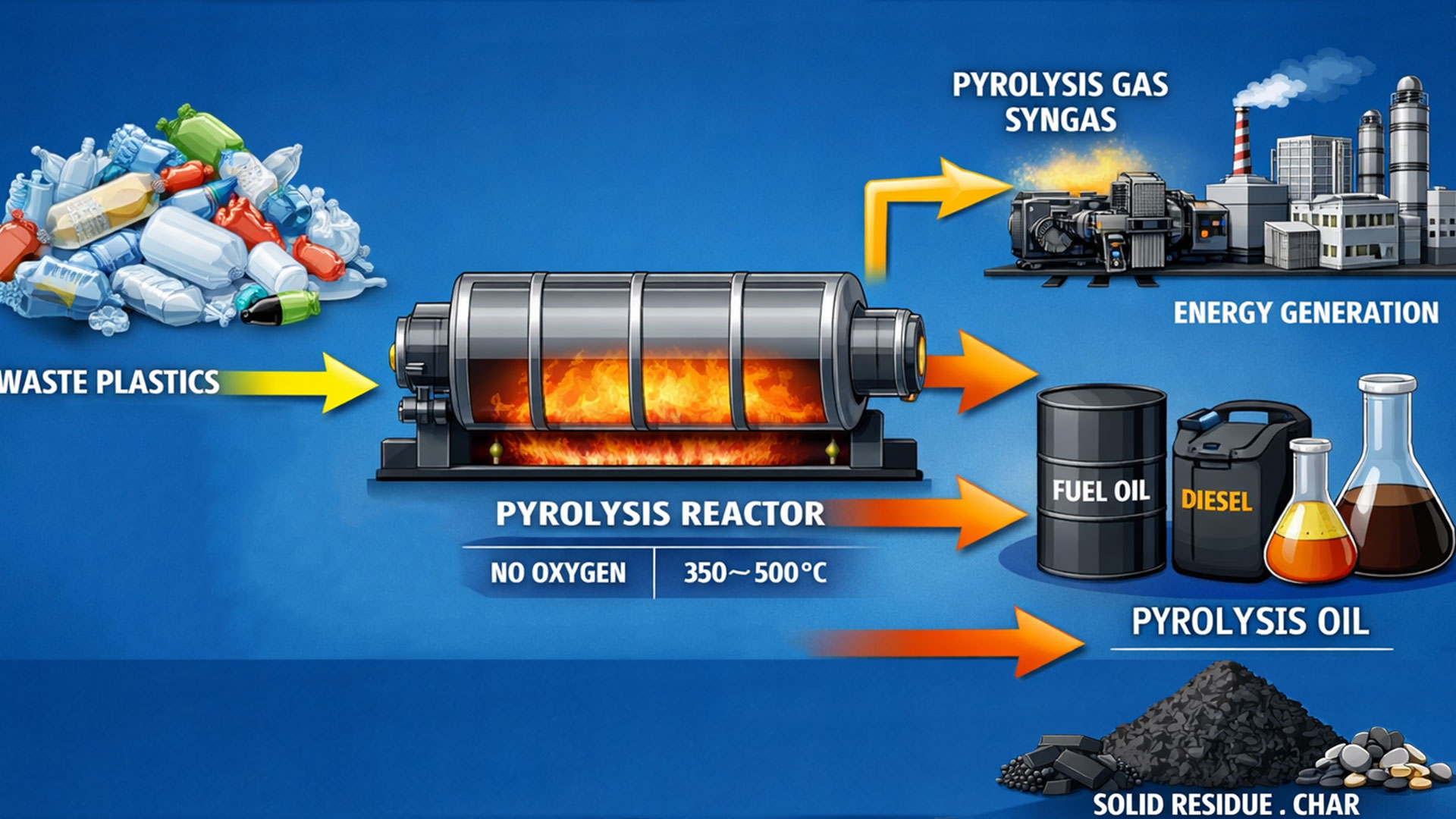

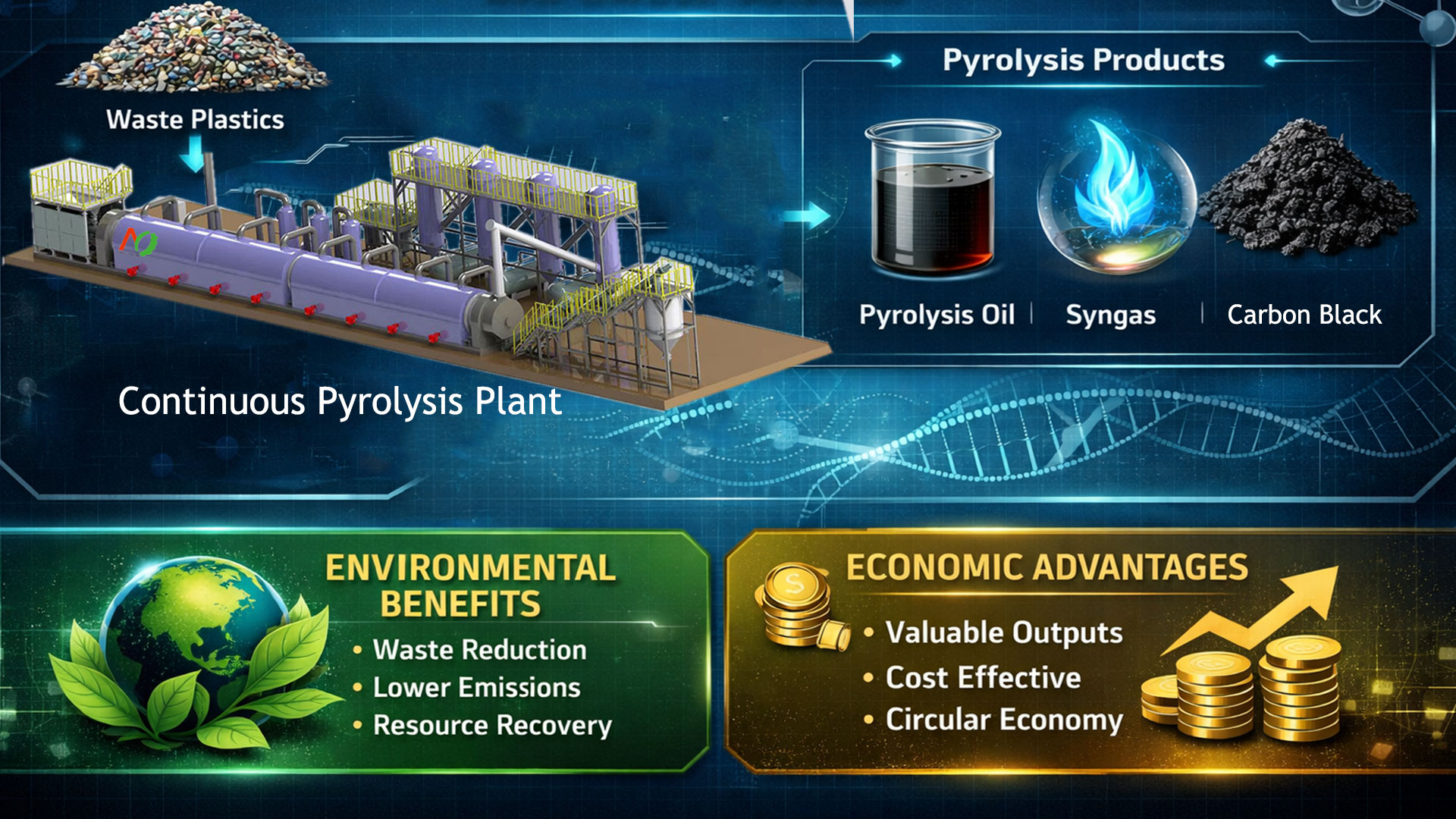

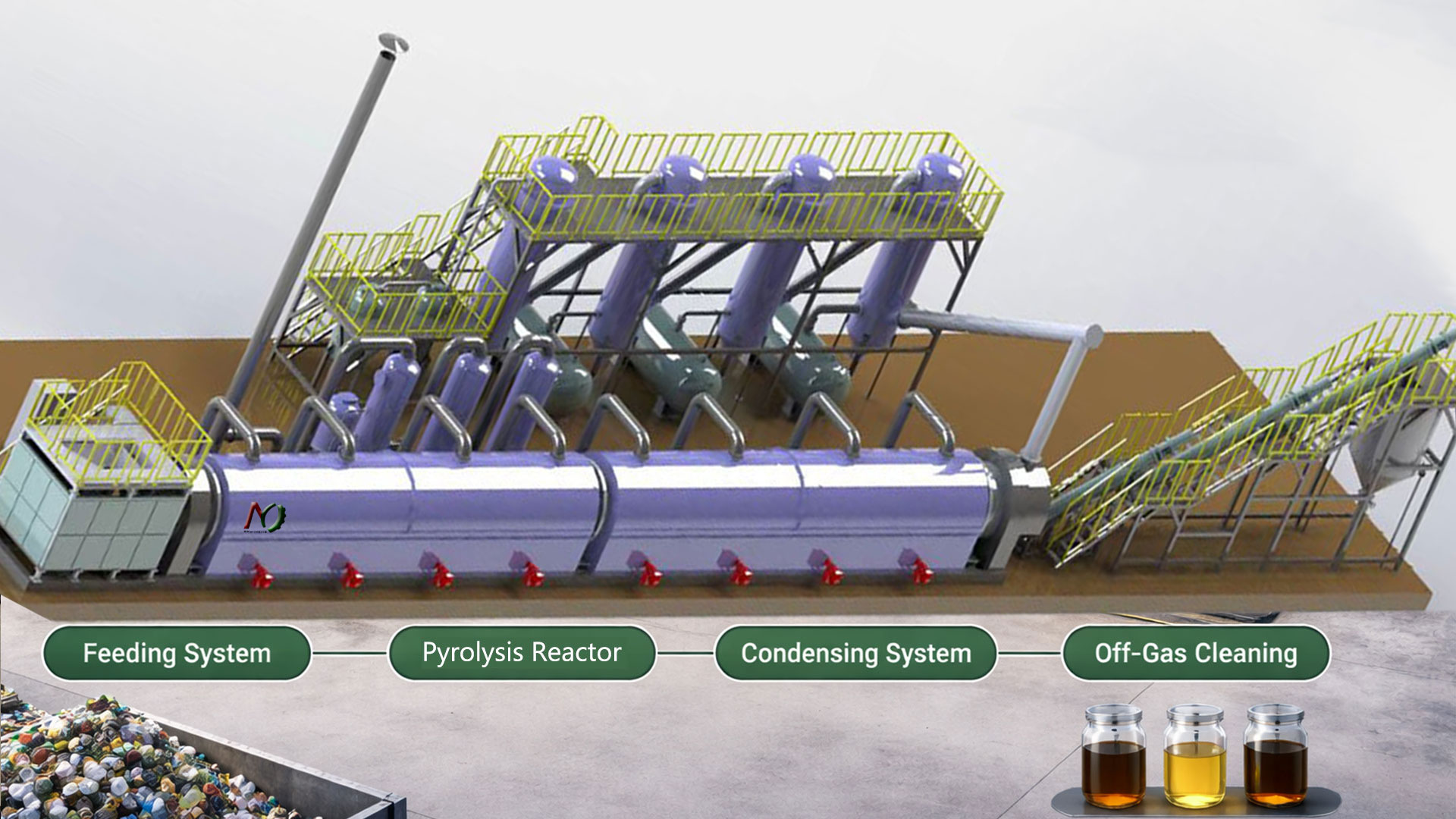

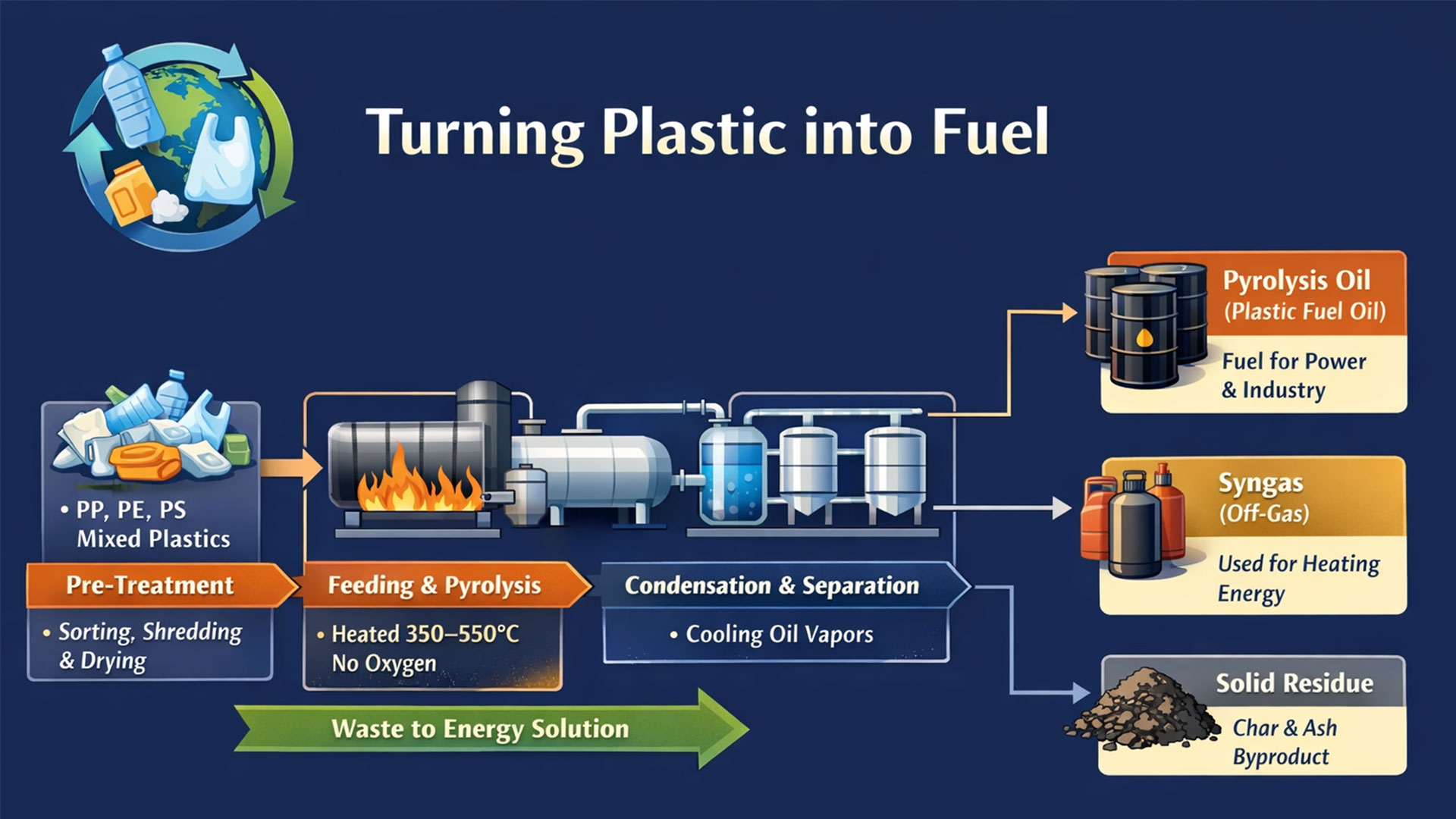

Pyrolysis Of Waste Plastics Into Fuels

Pyrolysis of waste plastics into fuels, a common method of thermochemical conversion, is a popular and promising option in municipal solid waste recycling. Compared to biological recycling, pyrolysis of waste plastics is easier to scale up and can handle unsorted and contaminated waste. Among numerous thermochemical pathways, pyrolysis has received considerable attention in recent years … Read more