The principle of biomass resource utilization is based on thermochemical conversion. A pyrolysis machine for biomass heats solid waste to a specific temperature range in an oxygen-free or low-oxygen environment. This causes a complex thermal decomposition reaction, transforming the waste biomass into biochar, syngas, and tar.

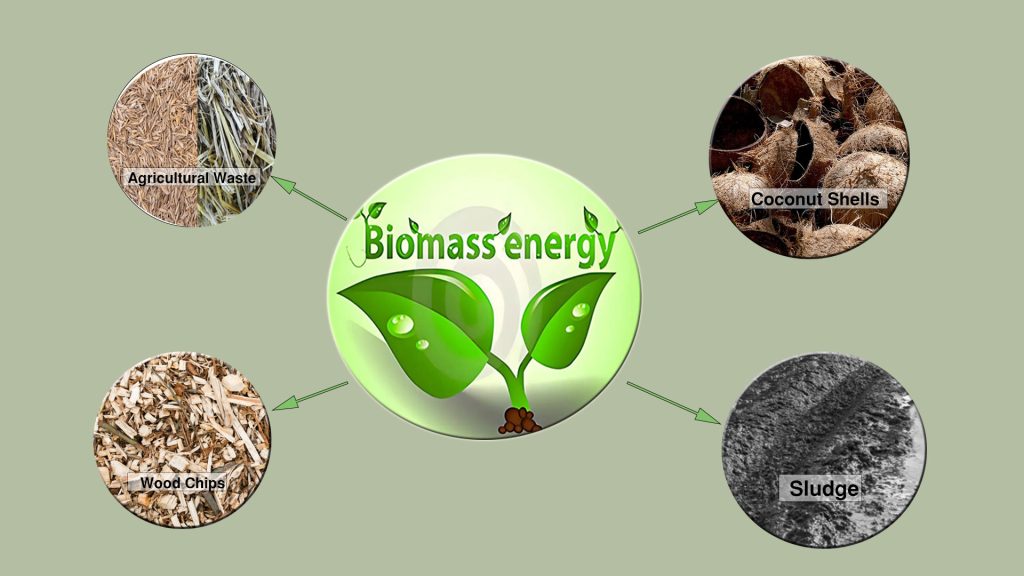

Biomass resources are zero-carbon, clean, stable renewable resources. Promoting the efficient conversion and utilization of biomass is a key step in implementing green, low-carbon, and circular development. Biomass resources are widely sourced from agriculture, industry, and everyday life. They are diverse, readily available, and relatively inexpensive.

Potential of Biomass Resources

- Agricultural Waste: Globally, over 3 billion tons of crop straw are produced annually, of which less than 30% is effectively utilized.

- Forestry Byproducts: Sawdust, branches, wood chips are often burned or landfilled at low value.

- Livestock and Poultry Manure: Livestock manure emissions are significant and a significant source of the greenhouse gas methane.

- Municipal Organic Waste: Food waste and waste oils and fats have potential energy value.

- Energy Crops and Algae: High-yield raw materials such as switchgrass, Miscanthus, sweet sorghum, and microalgae.

Research shows that if biomass is utilized wisely globally, its renewable energy potential could replace 10–14% of global primary energy consumption. Furthermore, it could bring significant emissions reduction benefits.

Unlike wind and solar power, biomass naturally captures atmospheric CO₂ during its growth process. Converting the waste biomass into energy and combining it with carbon capture and storage (CCS) creates a closed loop of “carbon absorption + energy + carbon sequestration.” Biomass pyrolysis machine, which convert biomass into biochar energy, is crucial for achieving carbon neutrality.

How the Pyrolysis Machine for Biomass Achieves Carbon Neutrality?

Pyrolysis machine for biomass have demonstrated remarkable environmental benefits in the process of converting solid waste into resources.

Biomass pyrolysis is a thermochemical conversion process conducted under oxygen-free or low-oxygen conditions. Compared to traditional incineration, it significantly reduces carbon dioxide emissions. Research shows that CO2 emissions from biomass pyrolysis are only 30%-50% of those from traditional incineration. This is because biomass absorbs a significant amount of CO2 during its growth, making the CO2 emissions from pyrolysis carbon neutral. It does not contribute significantly to atmospheric CO2 concentrations, thus helping to mitigate global climate change.

The biomass pyrolysis product biochar has the potential to replace traditional highly polluting materials, thereby reducing environmental pollution. Biochar can replace traditional chemical fertilizers and soil conditioners, sequestering carbon in the soil and reducing greenhouse gas emissions. It also improves soil quality, reduces fertilizer use, and reduces agricultural non-point source pollution.

The biomass pyrolysis process produces relatively little secondary pollution. The pyrolysis process is carried out under strictly controlled conditions, effectively preventing the production of these harmful substances. Furthermore, the exhaust gases generated by pyrolysis machine for biomass meet emission standards after appropriate treatment. Pyrolysis machine for biomass have a minimal impact on the environment, achieving harmless and environmentally friendly solid waste treatment.

Biomass Pyrolysis Equipments Applications

As a professional solid waste pyrolysis expert, Mingjie Group designs and manufactures continuous biochar production equipment. These biomass pyrolysis equipments are used in a variety of biomass pyrolysis projects, including rice husk charcoal making machine, wood charcoal making machine, coconut shell charcoal making machine, and straw charcoal making machine.

The pyrolysis machine for biomass has opened up a new path for solid waste resource utilization, significantly broadening its utilization options. Biomass pyrolysis equipment can process a wide range of solid waste types, including agricultural and forestry waste, sewage sludge, and animal manure.

The pyrolysis machine for biomass transforms waste into high-value-added biochar, bio-oil, and combustible gas. Biochar is widely used in soil improvement, effectively improving soil aeration and water retention, and promoting crop growth. Bio-oil, after further refining and processing, can be used as fuel for industrial production and transportation. Combustible gas can be directly used for power generation and heating, achieving efficient energy utilization.