Pyrolysis of E Waste is primarily applied to the refined recycling of waste PCBs, the recycling of plastics from waste household appliances, the separation of cables and composite materials, and the deep resource recovery of waste mobile phone dismantling plants.

The value of pyrolysis technology in the field of electronic waste treatment ultimately needs to be validated by the successful implementation of industrial-scale projects.

Several countries worldwide have established electronic waste pyrolysis plants. German and Swiss Pyrolysis of E Waste projects focus on environmental protection and metal recycling, while Japanese and South Korean electronic waste pyrolysis projects focus on the refined recovery of precious metals.

These Pyrolysis of E Waste projects have verified the core advantages of pyrolysis technology: volume reduction, harmlessness, and resource recovery.

Electronic Waste Management

Electronic waste encompasses discarded mobile phones, computers, home appliances, and industrial electronic equipment. Specifically, it can be divided into three core components:

- Metal Resources: Includes precious metals such as gold, silver, and palladium, as well as basic metals such as copper, aluminum, and iron. The total metal content accounts for 30%-50% of the weight of electronic waste.

- Organic Polymer Materials: Mainly plastics and rubber, accounting for approximately 30%-40%. Some plastics contain toxic additives such as brominated flame retardants (BFRs) and phthalates.

- Hazardous Impurities: Includes heavy metals such as lead, cadmium, mercury, and hexavalent chromium, as well as persistent organic pollutants (POPs) such as dioxins and polybrominated diphenyl ethers (PBDEs) produced by the combustion of flame retardants.

What is Pyrolysis of E Waste?

Pyrolysis of E Waste refers to the process of heating organic solids to 350–800℃ under anaerobic or oxygen-deficient conditions, decomposing them into small-molecule gases, liquid oils, and solid residues.

This is particularly useful for electronic waste, especially discarded printed circuit boards (PCBs), plastic casings, cables, wire harnesses, and small electronic components.

Pyrolysis of E Waste effectively separates organic and inorganic matter, enabling the recovery of pyrolysis products such as metals, pyrolysis oil, and combustible gases from electronic waste.

Electronic Waste Pyrolysis Process

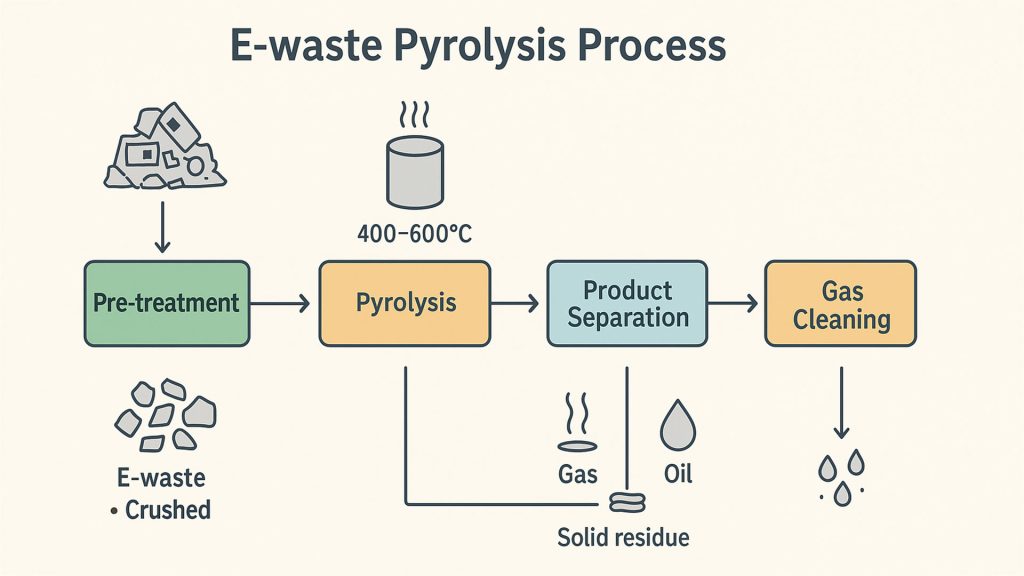

Pretreatment

Pretreatment is a crucial preparatory step before Pyrolysis of E Waste, directly affecting the stability of the pyrolysis process and the purity of the products. It mainly includes disassembly and sorting, crushing and separation, and drying to remove impurities.

Pyrolysis Reaction

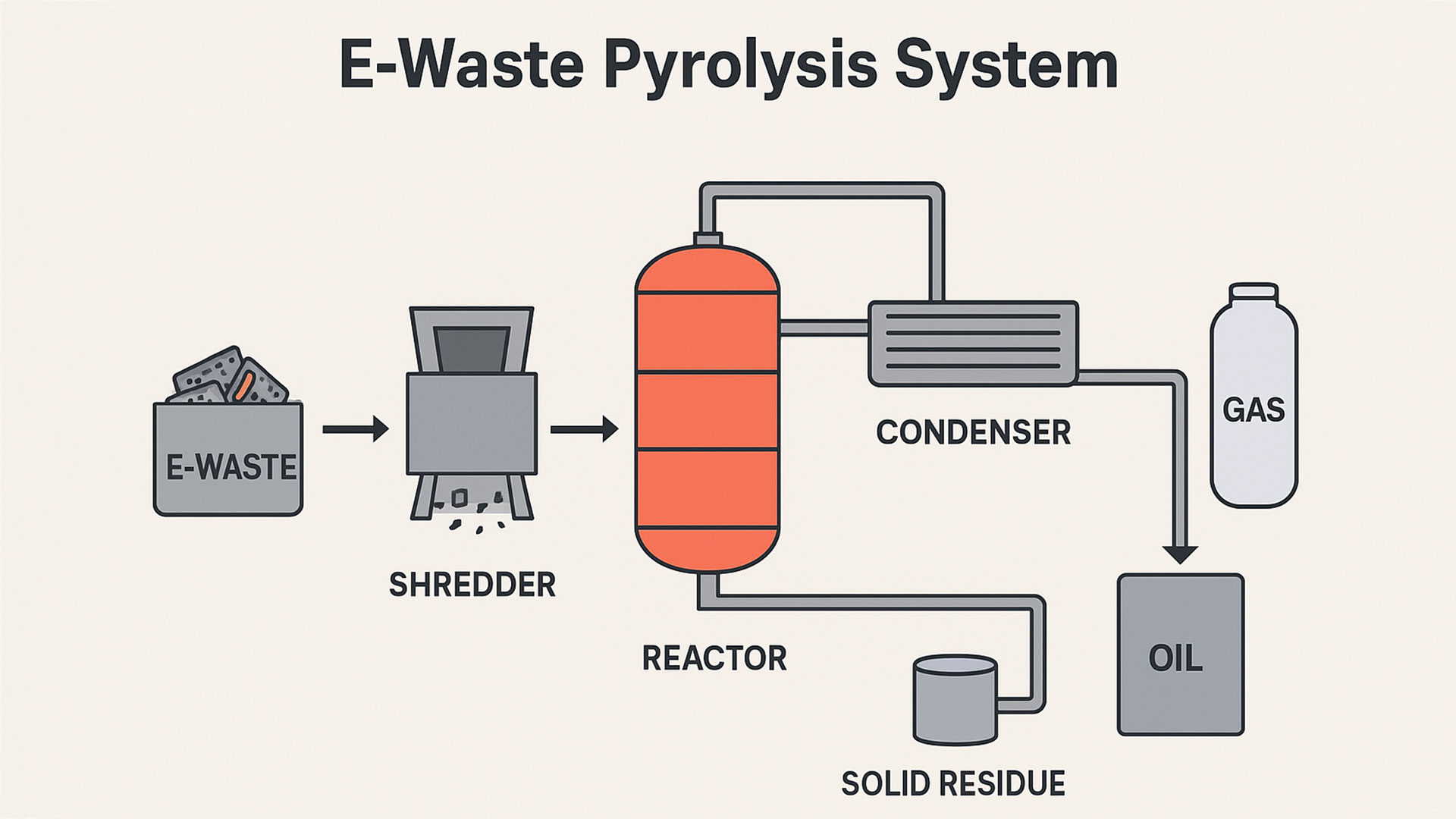

The pretreated materials enter the pyrolysis reactor, where they undergo a thermal decomposition reaction under anaerobic, high-temperature conditions.

At high temperatures, the plastic breaks carbon-carbon bonds, generating small-molecule hydrocarbons of C1-C12. Some of this condenses into pyrolysis oil, while the uncondensed portion forms syngas.

The brominated flame retardant decomposes at 400-600℃, releasing hydrogen bromide (HBr) and brominated hydrocarbons. This must be removed by a subsequent flue gas treatment system to prevent equipment corrosion or environmental pollution.

Metals such as gold, silver, and copper remain in a solid state. They react with glass fibers and ceramics to form pyrolysis residues.

Product Separation

The pyrolysis products of waste electronics require a multi-step separation process to separate solid, liquid, and gaseous products.

Gas-Liquid Separation: The mixed gas produced by pyrolysis enters a condenser, where most of the organic vapor is condensed into pyrolysis oil. The uncondensed syngas, after purification, can be used as fuel to provide heat to the pyrolysis furnace.

Liquid Purification: Pyrolysis oil contains impurities such as moisture, bromides, and heavy metal ions. It needs to be purified by distillation, extraction, or adsorption to remove impurities and increase the calorific value of the pyrolysis oil, making it suitable for use as fuel or chemical raw materials.

Solid Processing: Pyrolysis residue is processed through magnetic separation, electrostatic separation, and chemical leaching to achieve efficient recovery of metal resources, with a recovery rate exceeding 95%. The remaining glass fiber can be used as an additive in building materials.

Environmental Treatment

The pyrolysis of E Waste process may generate pollutants such as hydrogen bromide, dioxins, and dust, requiring a comprehensive environmental treatment system.

Acid Gas Removal: Alkaline absorbents (such as sodium hydroxide solution) are used to neutralize acidic gases such as hydrogen bromide and hydrogen chloride, preventing equipment corrosion.

Dioxin Control: Dioxin formation is suppressed using the “3T principle” (high temperature > 850℃, residence time > 2 seconds, thorough mixing). Activated carbon adsorption is also used to remove residual dioxins.

Dust Treatment: Cyclone dust collectors and bag filters are used to remove dust from the flue gas, preventing dust from being emitted with the gas or affecting the quality of the pyrolysis oil.