The primary purpose of pyrolysis of solid waste is to achieve harmless disposal. It is a thermochemical conversion technology. Pyrolysis of solid waste uses heat in the absence or absence of oxygen to break down organic matter into storable fuels (pyrolysis oil, syngas) and a solid residue (carbon black/biochar). This is fundamentally different from incineration (oxygen combustion).

The pyrolysis process for solid waste disposal differs fundamentally from incineration. Incineration requires ample oxygen to ensure complete combustion of the material. Pyrolysis, however, requires little or no oxygen, resulting in either no combustion or only partial combustion.

Pyrolysis equipment uses indirect heating to provide the heat required for the pyrolysis process when processing solid waste (tires, plastics).

The products of pyrolysis of solid waste and incineration are significantly different. Incineration produces large amounts of flue gas, which is difficult to handle and poses serious environmental risks. Incineration has no other means of utilizing the sensible heat. However, the combustible gases and oils produced by pyrolysis can be recycled in various ways, offering high energy recovery and minimal environmental pollution.

Pyrolysis Of Solid Waste

Pyrolysis treatment is suitable for organic solid waste with a certain calorific value. The Pyrolysis Of Solid Waste can process a variety of materials, including municipal solid waste, oil sludge, industrial waste such as plastics, rubber, and tires, and agricultural waste such as crop straw and livestock manure.

The pyrolysis of organic solid waste is a complex, continuous chemical reaction process. It involves complex reactions such as bond breaking and isomerization.

During the pyrolysis process, intermediate products undergo two transformations: One is a cracking process, from large molecules to small molecules and ultimately to gases. The other is a polymerization process, from small molecules to larger molecules.

Typically, the pyrolysis process of organic matter begins with dehydration, followed by demethylation. The water produced in the first reaction reacts with the methine groups in the bridging moiety of the second reaction product. Further increasing the temperature, the aromatic compounds produced in these reactions undergo further cracking, dehydrogenation, condensation, and hydrogenation.

Waste Pyrolysis Products

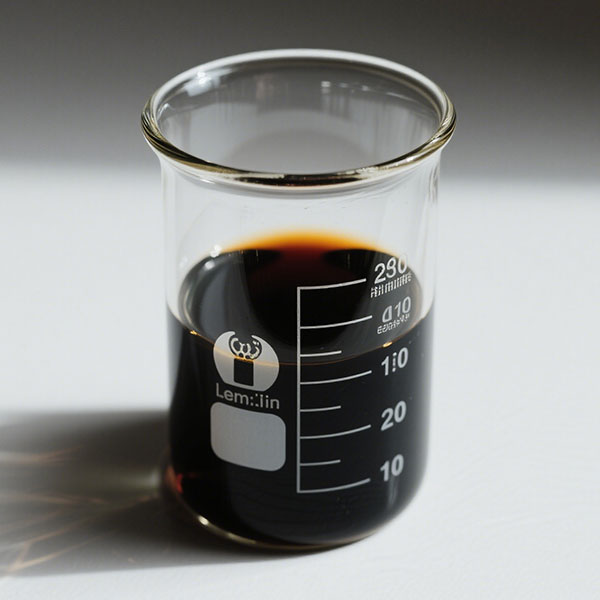

Pyrolysis plant can store the heat stored in solid waste in the form of combustible gas, oil, solid charcoal, etc. Thus, solid waste is converted into valuable fuel that can be stored and transported. Pyrolysis products occur in three forms: gas, liquid, and solid. Pyrolysis products vary significantly depending on the type of waste and the pyrolysis reaction conditions.

The temperature range of the pyrolysis reactor’s heat-absorbing reduction zone is 320°C-540°C, with carbon black as the primary pyrolysis product.

The temperature range of the heat-releasing oxidation zone is 760°C-1150°C, with heavy oil-like substances as the primary pyrolysis product. High-temperature pyrolysis should be above 1000°C, with gas as the primary pyrolysis product. The pyrolysis gas products can be condensed and separated to obtain fuel oil and fuel gas.

Pyrolysis Gas Purification

The purification of pyrolysis gas products should include cooling, dust removal, and deacidification.

Depending on the required heat energy utilization, the cooling method for pyrolysis gas products can be either waste heat recovery or direct spray cooling.

Bag filters should be used as dust collectors. Deacidification systems can utilize spray drying, fluidized bed deacidification, or wet deacidification processes, depending on the needs.

Applications of Solid Waste Pyrolysis

Due to its unique advantages, Mingjie pyrolysis plant has been widely used in pyrolysis of solid waste treatment across multiple sectors.

MSW Pyrolysis

For municipal solid waste treatment, several cities in the Philippines have introduced our advanced pyrolysis equipment to treat municipal solid waste. The pyrolysis plant achieves efficient waste conversion by precisely controlling the pyrolysis temperature and reaction time.

Pyrolysis oil is refined by the pyrolysis oil distillation plant and used as industrial fuel. The combustible gas produced by pyrolysis is used for power generation, providing a portion of the local electricity supply. The solid char is used to make activated carbon for applications such as water treatment and air purification. Pyrolysis of solid waste reduces and decontaminates municipal waste. It also converts waste into a usable resource, generating significant economic and environmental benefits.

Waste Tire Pyrolysis

In the field of industrial waste treatment, a Thai company is using pyrolysis technology to process scrap tires. The tyre pyrolysis plant converts scrap tires into combustible gas and liquid oil. The combustible gas is used to generate heat and power during the pyrolysis process, while the liquid oil, after further processing, can be used as a chemical raw material. The metals are recycled and reused in related industries such as automotive manufacturing.

Pyrolysis of solid waste not only reduces waste disposal costs for companies, but also increases resource recovery rates.

Waste Biomass Pyrolysis

Agricultural waste treatment is also an important application area for pyrolysis technology. Our biomass carbonization plant utilizes a modular structure, integrating multiple functions, including pyrolysis, and carbonization. This biomass pyrolysis plant offers new insights into the energy utilization of agricultural waste.

Biomass pyrolysis plants are widely used in wood charcoal making, straw charcoal making, rice husk charcoal making, coconut shell charcoal making, sawdust charcoal making and bamboo charcoal making. Our biomass pyrolysis machines are used in biochar production projects in many countries, such as Vietnam, China, Chile, South Africa, Tanzania, Finland, etc.

The pyrolysis of solid waste realizes the conversion of waste biomass into biochar. It plays an important role in soil improvement, carbon sequestration and other fields, and has significant environmental and economic benefits.