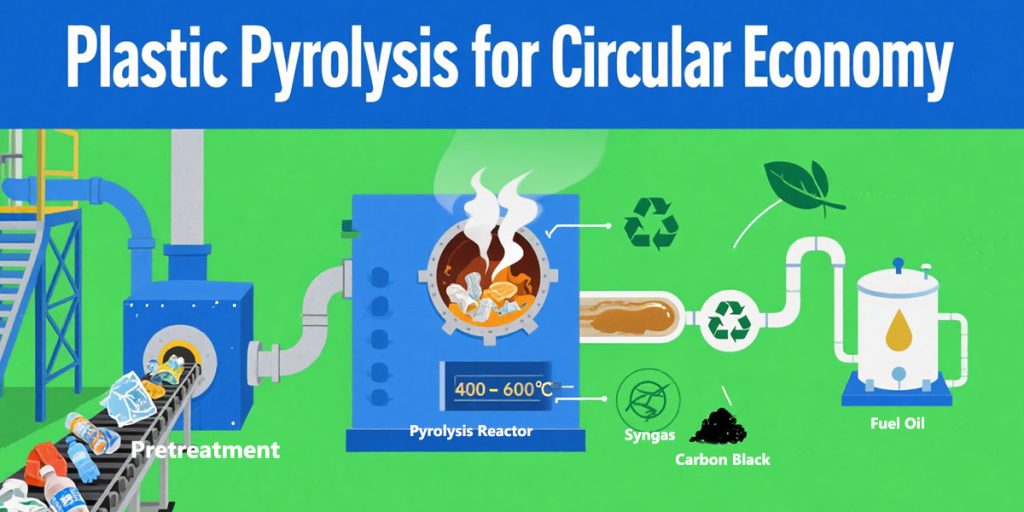

Plastic pollution has long been considered a global problem. Currently, a growing number of advanced pyrolysis plastics recycling technology is being implemented, enabling the efficient conversion of waste plastics into fuel. Pyrolysis heats plastic waste to high temperatures in an anaerobic environment, effectively converting it into hydrocarbons (similar to those extracted from crude oil), thereby producing plastic.

Pyrolysis plastics recycling is considered part of the plastics cycle economy. In the future, we may no longer need to rely on crude oil to produce plastic, but instead be able to reuse existing plastic resources indefinitely.

9% Waste Plastic is Recycled

A study shows that only 9% of plastic produced by humans is recycled, with the majority ending up in landfills. This has a devastating impact on the environment. Whether incinerated or landfilled, the disposal of waste plastic releases significant amounts of greenhouse gases. Furthermore, the health risks posed by plastics are a growing concern. Yet, plastic remains a necessity in modern life because it is so practical.

Traditionally, waste plastics require sorting, even manual sorting to isolate the high-quality plastics, before they can be sent for mechanical recycling. Mechanical recycling involves a series of processes, including washing, shredding, grinding, and melting, to transform the waste plastic into pelletized plastic raw materials for recycling. This method is particularly effective for plastics such as polyethylene terephthalate (PET). According to statistics, PET waste accounts for approximately 7% of total plastic waste, of which over 90% is recyclable.

However, most waste plastics are not suitable for mechanical recycling. Even if they are recycled, the performance of the resulting products is unlikely to match that of virgin materials. Furthermore, these recycled plastics cannot obtain food contact approval and are therefore prohibited from use in food packaging.

For example, recycled PET is rarely used again in beverage bottles. Most of it is “downcycled” into furniture, carpets, and insulation. Furthermore, the mechanical recycling process causes some degradation of the plastic. The quality of the plastic decreases with each cycle until it is no longer usable.

Pyrolysis Plastics Recycling Technology

Advanced recycling technologies use chemical methods to recycle plastics, allowing them to be repeatedly returned to their original state. In theory, chemical recycling can break down even the most complex waste into pure raw materials. These can then be remade into plastics or other industrial products with properties identical to the original plastic. This plastics cycle can continue indefinitely.

Currently, the most mature and advanced plastics recycling technology is pyrolysis. This method returns plastics to their original state. In an oxygen-free environment, at temperatures exceeding 500°C, plastic pyrolysis equipment converts plastics into pyrolysis oil, carbon black and syngas. These can then be further used to synthesize a variety of useful chemical products.

What Types of Plastics can be Recycled through Pyrolysis?

The pyrolysis process is highly efficient for processing and recycling plastic waste such as polyethylene(PE), polypropylene(PP), and polystyrene(PS). These difficult-to-recycle plastics are often used to make consumer packaging, such as milk bottles, shrink film, and microwaveable food containers. These single-use items account for the majority of plastic waste generated.

Polyvinyl chloride (PVC) molecules contain chlorine atoms. During pyrolysis, not only hydrocarbons are produced, but also hydrogen chloride gas is released. This gas must be properly handled to prevent pollution.

Pyrolysis Plant for Plastics Recycling

Plastic pyrolysis plant is crucial equipment for pyrolysis plastics recycling. Mingjie plastic pyrolysis equipment features high-temperature and corrosion resistance, along with excellent sealing properties, to meet the high-temperature, high-pressure, and oxygen-free or oxygen-deficient reaction conditions required during the pyrolysis process. To ensure precise control of the reaction process, we provide automated feeding system and exhaust gas purification system.

Plastic pyrolysis technology provides a comprehensive solution for the recycling of waste plastics. Pyrolysis plastic recycling technology transforms waste plastics into valuable resources. It reduces the environmental impact of plastic waste while enabling resource recycling. Many governments and recyclers are now adopting this environmentally friendly and efficient plastics disposal method.

Combined with traditional mechanical recycling, plastic pyrolysis plant can significantly increase the variety of recyclable plastic waste. Pyrolysis plastics recycling also contributes to a circular economy, enabling the continued use of plastic waste as raw material.