As a key equipment to solve the dilemma of plastic pollution, pyrolysis waste plastic equipment is becoming more and more important under the current environmental protection situation. The pyrolysis machine can effectively treat waste plastics, and it is a vivid practice of transforming pyrolysis technology into plastic recycling.

Pyrolysis equipment plays a core role in the field of waste plastic treatment, achieving a gorgeous transformation from “white pollution” to “green resources”.

Mingjie Group has explored the principles of pyrolysis technology and continuously optimized the process of plastic pyrolysis equipment. From the diversified utilization of pyrolysis products to the practice of waste plastic pyrolysis projects at home and abroad. We have seen the huge potential and broad prospects of pyrolysis waste plastic equipment.

Global Pyrolysis Waste Plastic Project

In recent years, the application of pyrolysis equipment in the field of waste plastic treatment has gradually increased. A number of waste plastic pyrolysis plant projects have emerged both at home and abroad. The construction and operation of these pyrolysis plant projects mark the transition of pyrolysis technology from laboratory research to practical application. Pyrolysis waste plastic equipment provides a new way to solve the problem of waste plastic pollution.

Freepoint Eco-Systems in the United States is actively deploying waste plastic pyrolysis projects and working with Turkish waste management company Biotrend. It is developing advanced plastic recycling facilities in Izmir, Turkey, with an annual processing capacity of 60,000 tons.

Total Energy signed a contract with New Hope Energy in Texas, USA. It receives 100,000 tons of pyrolysis oil each year for its Taylor plant in Texas to produce recycled plastics.

New Hope Energy has been operating its Trinity Oak pyrolysis plant in Taylor as early as 2018. It signed a multi-year supply contract with Dow in 2022 and is currently planning to expand the plant.

BP signed a 10-year naphtha offtake agreement with Clean Planet Energy. BP will obtain the first batch of recycled petrochemical raw materials and ultra-low sulfur diesel produced by Clean Planet Energy’s 20,000 tons/year pyrolysis plant in Teesside, UK.

Chinese companies are also actively deploying pyrolysis waste plastic projects. They improve the pyrolysis waste plastic efficiency and product quality through technological innovation and pyrolysis equipment optimization.

Pyrolysis Of Waste Plastics Into Fuels

At present, there are three main processes for pyrolysis of waste plastics into fuels: thermal cracking, catalytic thermal cracking, and thermal cracking-catalytic modification.

Thermal Cracking

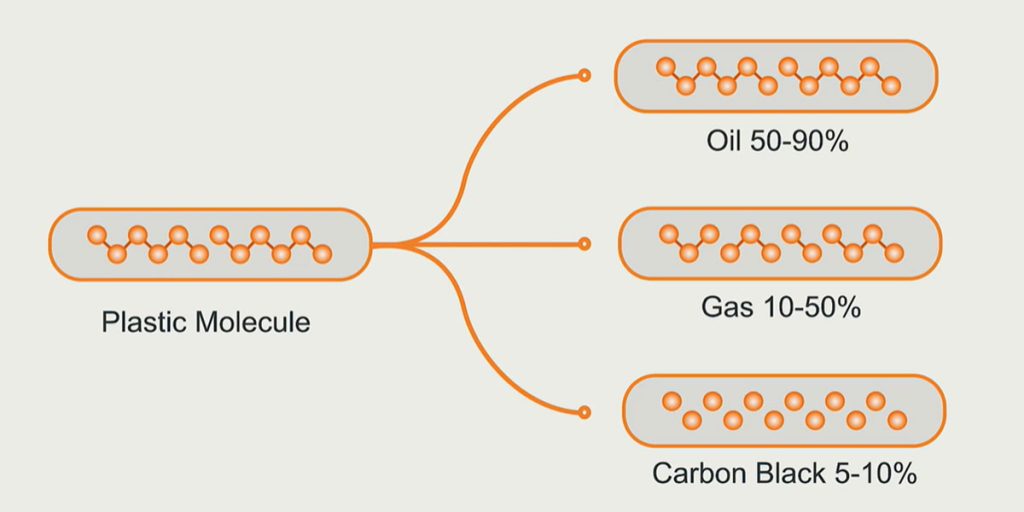

The thermal cracking method is the most basic pyrolysis waste plastic process and the earliest method used in the treatment of waste plastics. Its process is relatively simple. The waste plastics are placed in a pyrolysis reactor. In an oxygen-free or low-oxygen environment, a high temperature is provided by a heating and temperature control device to break and decompose the plastic macromolecular chain.

The advantages of the thermal cracking method are low investment, simple process, and no need for complex equipment and expensive catalysts. But its disadvantages are also very obvious. The cracking reaction temperature is high, the reaction time is long, and the production efficiency is low.

Catalytic Pyrolysis

Catalytic pyrolysis is developed on the basis of pyrolysis waste plastic. It adds catalysts, such as solid aluminum silicate, molecular sieve and other solid acid catalysts, to the pyrolysis process. These catalysts are like accelerators of chemical reactions. They can reduce the activation energy required for the reaction, so that the reaction can proceed quickly at a lower temperature.

Under the action of the catalyst, the plastic undergoes cracking, hydrogen transfer, condensation and other reactions. Products with relative molecular mass and structure within a certain range are generated and then separated. Compared with the pyrolysis waste plastic method, the catalytic pyrolysis method has the advantages of fast reaction rate and low energy consumption.

Pyrolysis – Catalytic Modification Method

Pyrolysis – catalytic modification method is a process that combines pyrolysis and catalytic pyrolysis, also known as a two-stage process. In the first stage of pyrolysis, waste plastics are pyrolyzed at high temperature to produce pyrolysis gas and some primary products. Then, the pyrolysis gas enters the second stage of catalytic modification, where it further reacts under the action of the catalyst to improve the quality of the product.

The advantage of the pyrolysis – catalytic modification method is its flexible operation. The batch pyrolysis plant can process mixed waste plastics with relatively low operating costs. Through catalytic reforming of pyrolysis gas, the content and quality of light fractions, such as gasoline and diesel can be improved.

In Summary

Although pyrolysis technology has shown great potential in the treatment of waste plastic. However, the global recognition of pyrolysis technology is still low, which has become the biggest obstacle to the promotion and application of pyrolysis technology.

From the perspective of regulatory policies, there are large differences in the definition and regulatory standards of pyrolysis technology among countries around the world. Consumers’ awareness and acceptance of pyrolysis technology are also seriously insufficient. In the market, consumers prefer traditional plastic products and are cautious about pyrolysis recycled plastic products.