The global pyrolysis waste to oil market is showing strong growth. According to data from relevant market research institutions, the global waste-derived pyrolysis oil market reached a considerable size in 2024. It is expected to grow further through 2030, maintaining a compound annual growth rate (CAGR) during the forecast period.

This growth trend is driven by the urgent global demand for sustainable energy and environmentally friendly solutions. With increasing emphasis on environmental protection and the increasing scarcity of traditional fossil fuels, pyrolysis waste to oil technology has garnered widespread attention and favor. It is an innovative technology that effectively treats waste and produces alternative energy.

Currently, a number of companies with leading technologies and market share in the pyrolysis waste-to-oil field have emerged globally.

Mingjie Group, with its advanced pyrolysis technology, has established a significant position in the global plastic waste to oil market. It specializes in the research and development of pyrolysis technology and equipment for plastics, tires, and oil sludge. By continuously optimizing pyrolysis processes and product quality, it has earned a strong reputation in the market.

Applications of Pyrolysis Waste to Oil

Pyrolysis plants can convert solid waste into pyrolysis oil, they have demonstrated broad and significant application value in multiple sectors. They provide strong support for waste resource utilization and energy mix optimization.

Alternative Fuels

In the fuel sector, pyrolysis waste to oil, as a promising alternative fuel, is gradually emerging in various energy-consuming industries. In industrial boilers and furnaces, pyrolysis oil can directly replace traditional fossil fuels, providing heat for industrial processes.

For example, large steel and cement plants require significant amounts of heat to maintain high temperatures during production. The use of pyrolysis oil can meet these energy needs. Compared to traditional fuels, pyrolysis oil produces relatively few pollutants during combustion, helping to reduce the negative environmental impact of industrial production.

Pyrolysis oil also has broad application prospects in the power generation sector. Some power plants have begun experimenting with pyrolysis oil as a power generation fuel. This process uses the heat generated by burning pyrolysis oil to drive steam turbines, generating electricity and converting waste into electricity. This approach not only provides a new solution to waste disposal issues, but also increases the proportion of renewable energy in electricity generation.

Raw Materials for Chemical Products

In the chemical industry, pyrolysis waste to oil is a key raw material source, providing a foundation for the production of numerous chemical products. Pyrolysis oil is rich in a variety of organic compounds, such as aromatic hydrocarbons and olefins. These components are key raw materials for the synthesis of polymer materials such as plastics, rubber, and fibers.

Through a series of chemical reactions and processing techniques, these organic compounds in pyrolysis oil can be converted into various plastic monomers, such as ethylene, propylene, and styrene. These monomers are then used to produce common plastic products such as polyethylene, polypropylene, and polystyrene.

In rubber production, certain components of pyrolysis oil can act as plasticizers and softeners, improving the processing and physical properties of rubber, and enhancing the quality and service life of rubber products.

Pyrolysis oil can also be used to produce chemical products, such as solvents and lubricants. Refining and purification of pyrolysis oil yields solvents with specific chemical compositions and physical properties. These solvents are widely used in industries such as coatings, inks, and adhesives, dissolving various organic substances and facilitating product preparation and application.

Through further processing and blending, pyrolysis oil can be used to produce various types of lubricants. These lubricate and protect mechanical equipment, reducing friction and wear and extending its service life.

Pyrolysis Waste to Oil Plant Manufacturer – Mingjie Group

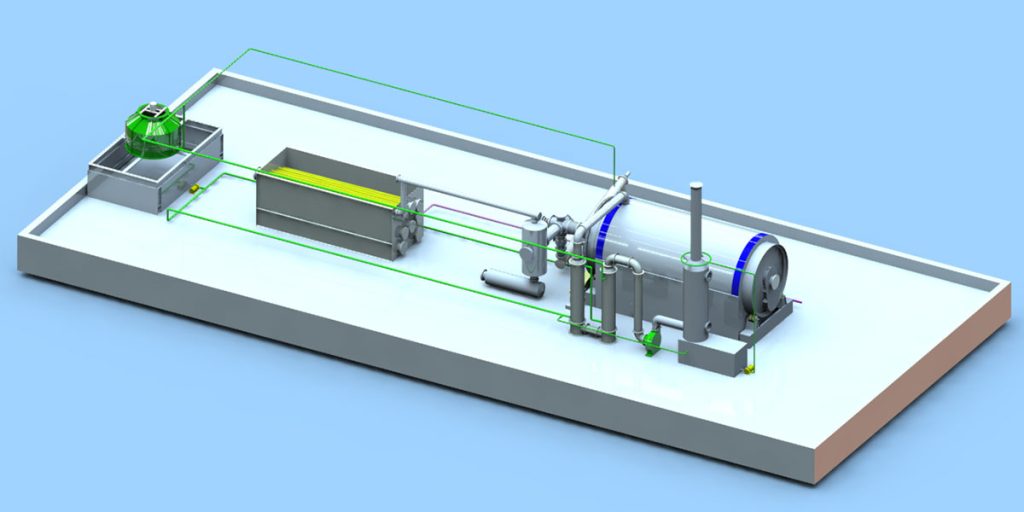

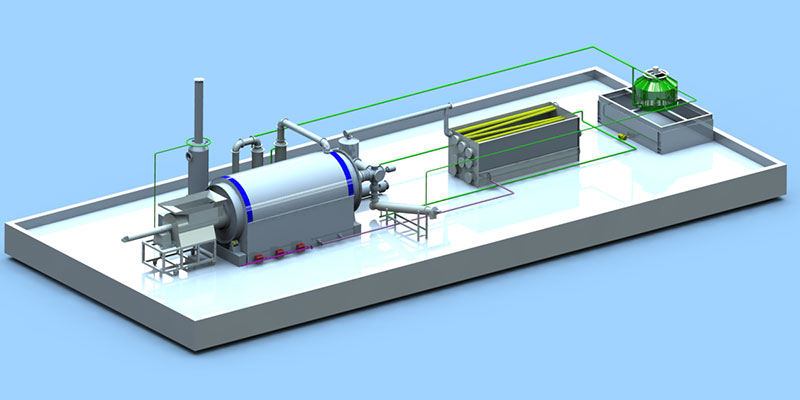

Mingjie Group is a professional pyrolysis plant manufacturer. We provide one-stop pyrolysis waste to oil solutions, from waste pyrolysis solution design to pyrolysis equipment manufacturing, installation and operation guidance of waste pyrolysis project.

In terms of process optimization, Mingjie Group is continuously exploring more efficient and energy-saving pyrolysis waste to oil processes. We offer batch, semi-continuous, and continuous pyrolysis solutions.

Continuous pyrolysis reactors enable uninterrupted waste feed and continuous product output, improving pyrolysis oil production efficiency. Advanced intelligent control technology enables precise control of the pyrolysis process, enhancing both the yield and quality of pyrolysis oil.

By improving the design of the pyrolysis reactor, we are enhancing heat transfer efficiency and making the pyrolysis process more uniform and stable. This further reduces energy consumption and production costs.

Energy recovery technology enables the syngas produced during the pyrolysis process to be used for equipment heating. Advanced exhaust systems purify the flue gas produced during the pyrolysis process to meet emission standards.